Head joint drainage device, wall system and method for draining moisture from a head joint

a head joint and drainage device technology, applied in the direction of girders, joists, transoms, etc., can solve the problems of affecting the flow of moisture through the wall cavity, exacerbate the problem, etc., and achieve the effect of preventing the passage of moistur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

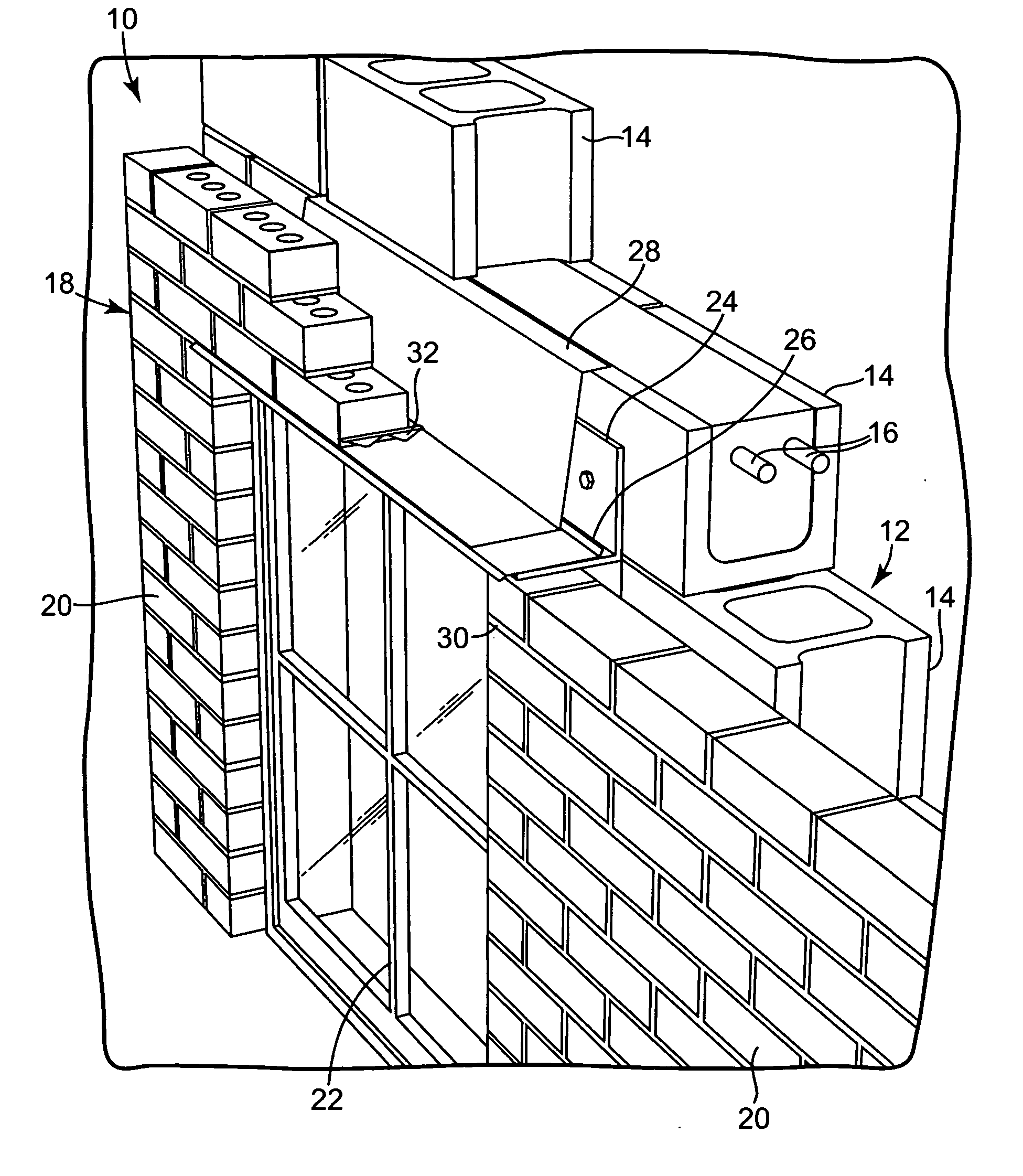

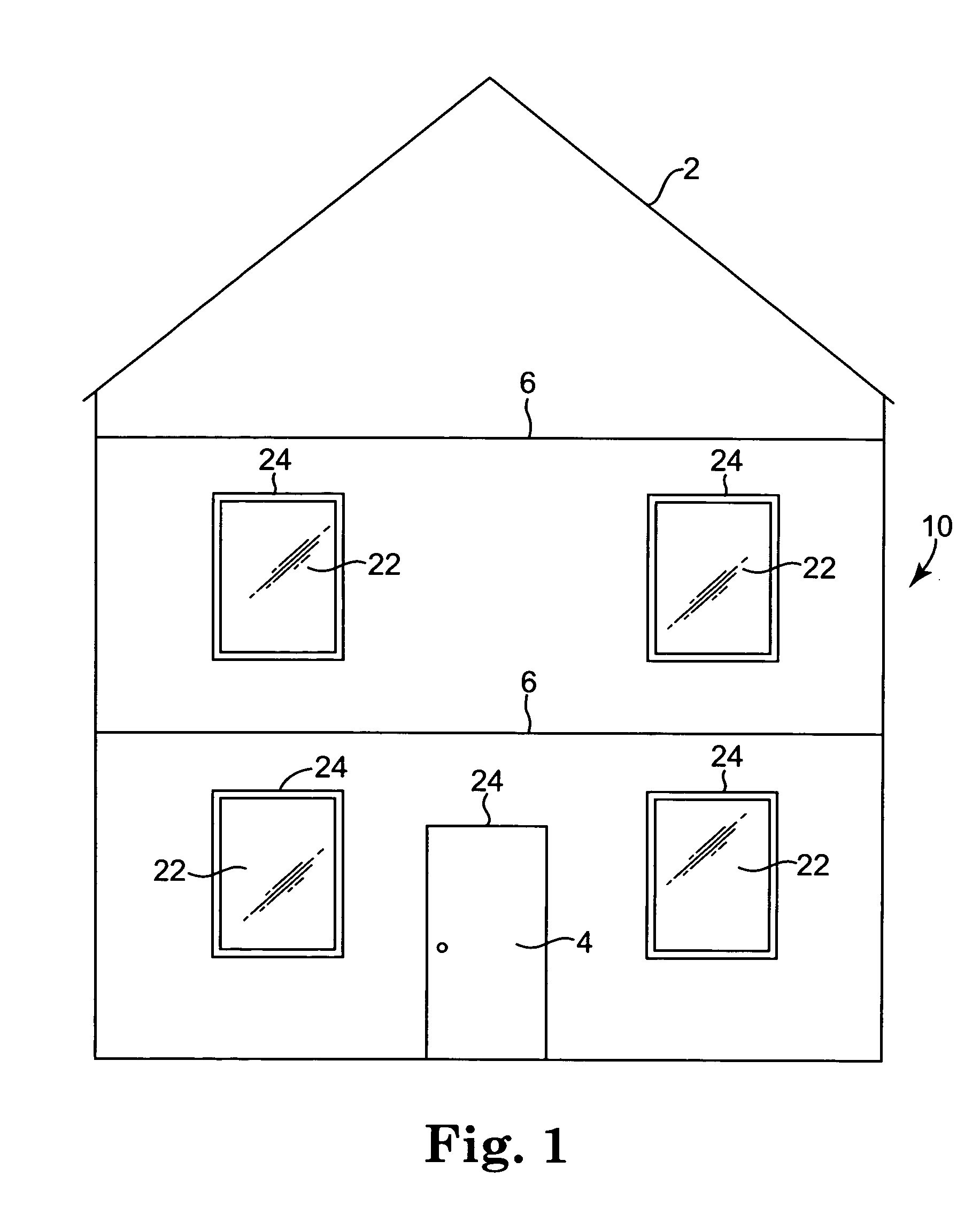

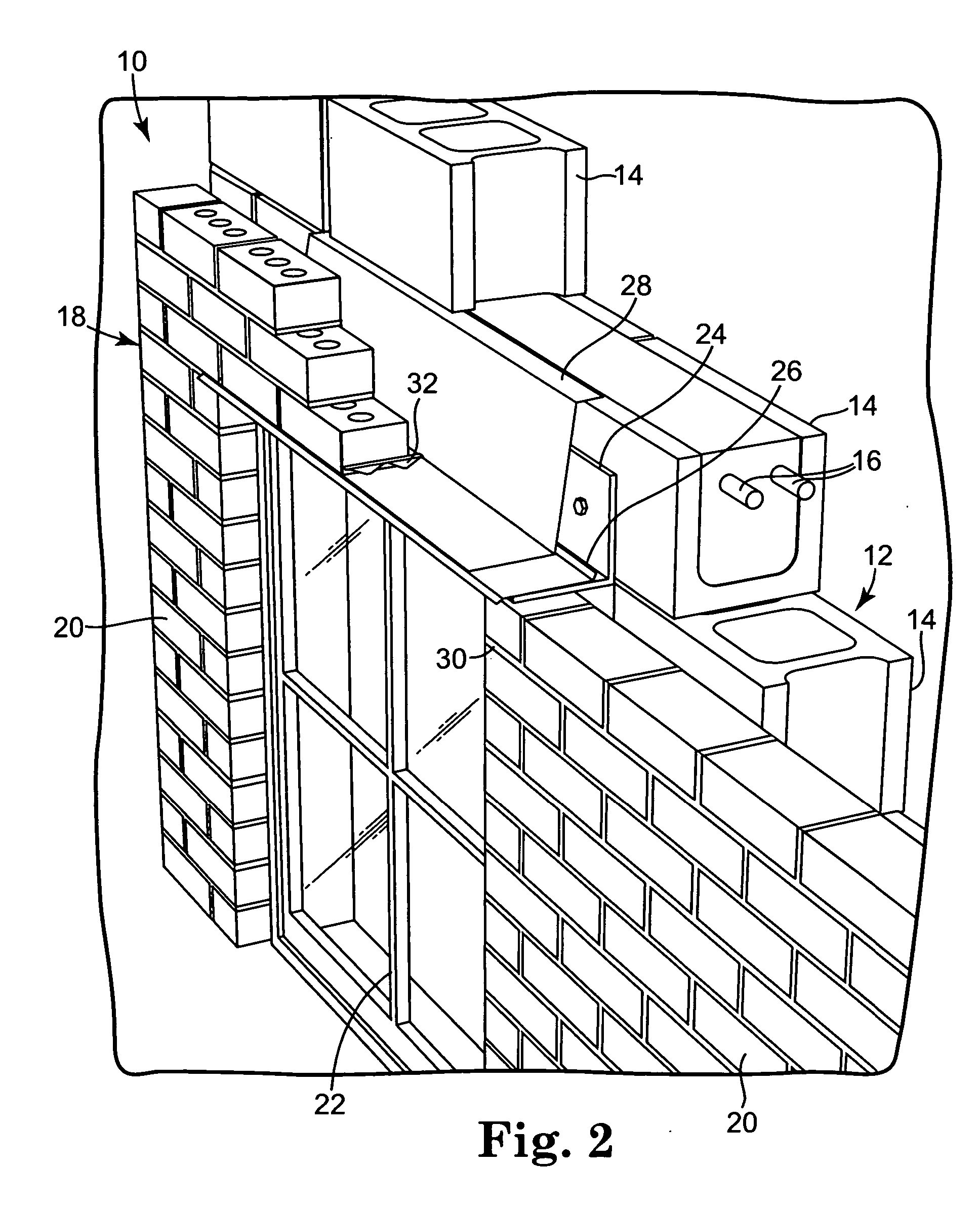

[0044] A head joint is formed in a wall structure when the wall structure has an opening in what would otherwise be an unbroken expanse of wall. Openings are commonly made in wall structures for windows and doors, for example. The wall structure essentially stops at the top of the window or door opening and, in the case of a window opening, may start again below the opening. The wall structure above the opening is typically supported by a structural header, designed to carry the load of the wall structure above the opening and spread the weight of that load the load bearing capacity of the wall structure on either side of the opening.

[0045] In the case of a wall structure having an a brick exterior, typically an exterior veneer of brick set in mortar, the weight of the wall structure above an opening is also distributed by a structural member to either side of the opening. With a brick wall structure, the load bearing member is typically called a lintel. A lintel is commonly constr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com