Mortar spreader for building wall and using method thereof

A grouting device and wall technology, which is applied in the field of brick or block masonry, can solve problems such as incompleteness, cracks in the wall, and messiness, so as to ensure thermal performance, save masonry mortar, and reduce the weight of the wall. effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

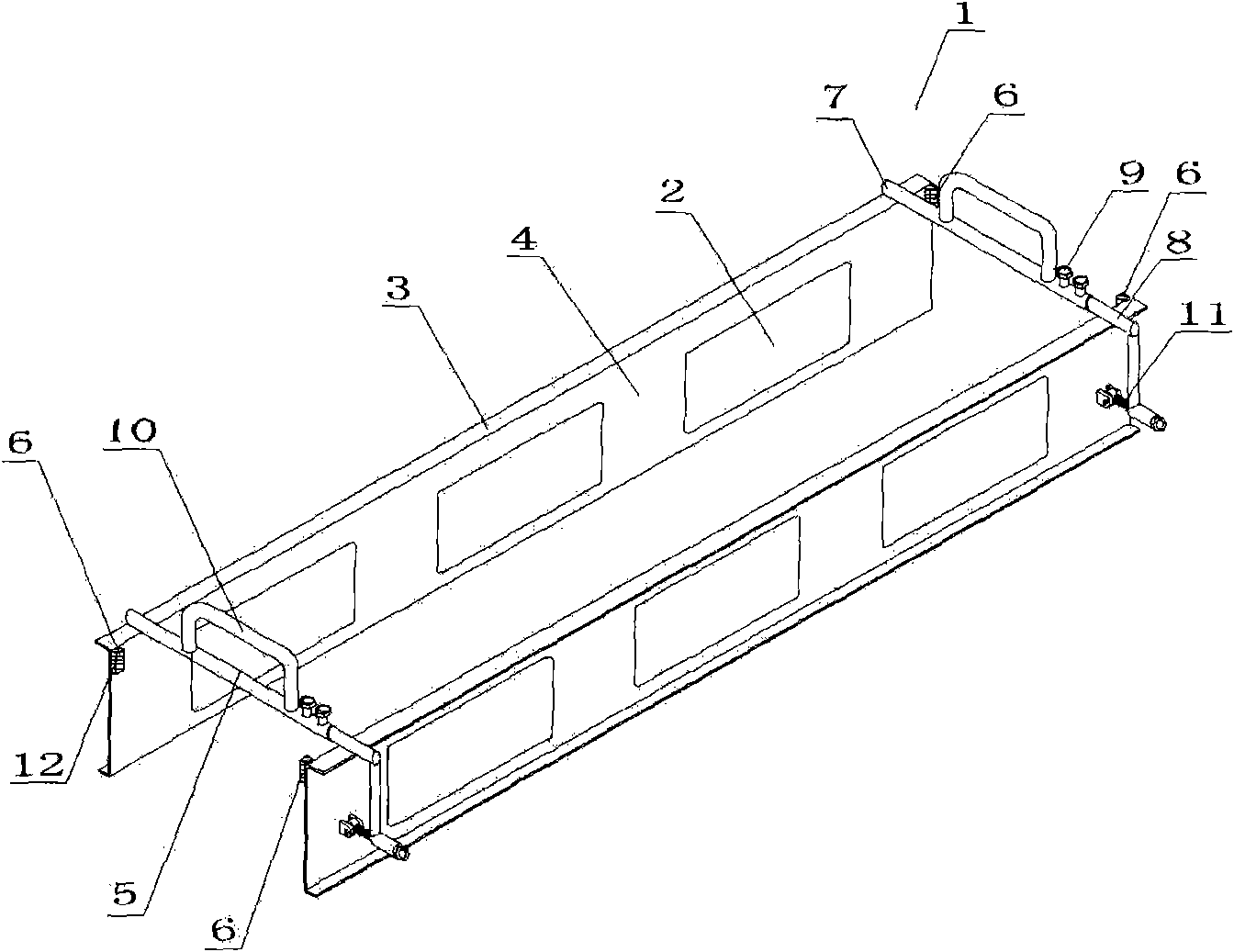

[0033] Technical scheme of the present invention figure 1 The dot-shaped thickness gauge paver 1 is connected by a side plate 4 with a hole 2 and a folded edge 3 through a connecting piece 5, and four dot-shaped thickness gauges 6 are arranged on the side plate 4, and the connecting piece 5 It consists of a fixed connecting rod 7 and a movable connecting rod 8. The fixed connecting rod 7 is provided with a positioning bolt 9 and a handle 10, and the movable connecting rod 8 is provided with an adjusting spring 11, which is connected with the side plate 4. The height 12 of the four point-like thickness gauges 6 is the grout thickness, usually 10-20 mm, which can be adjusted and determined according to the porosity of bricks or blocks.

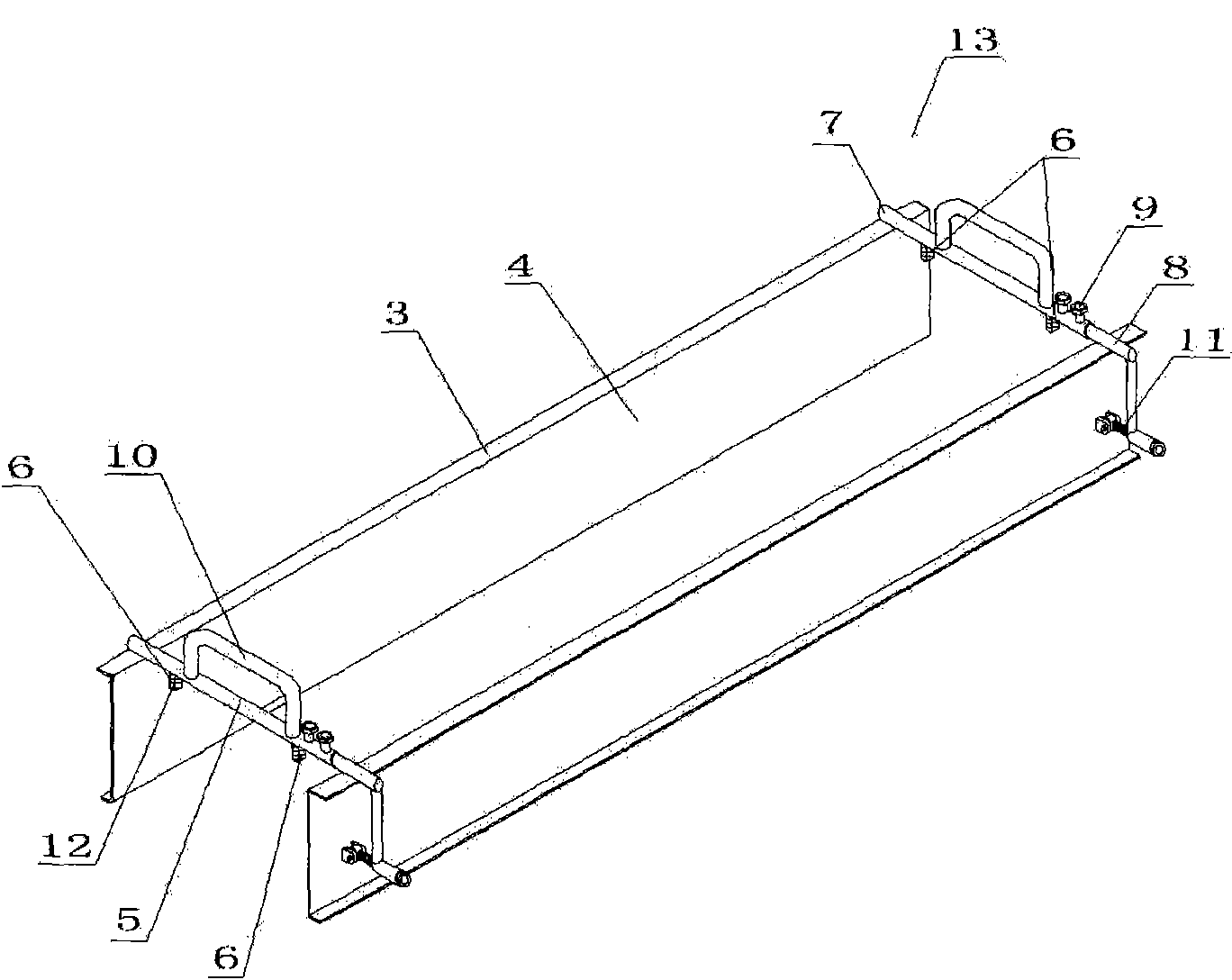

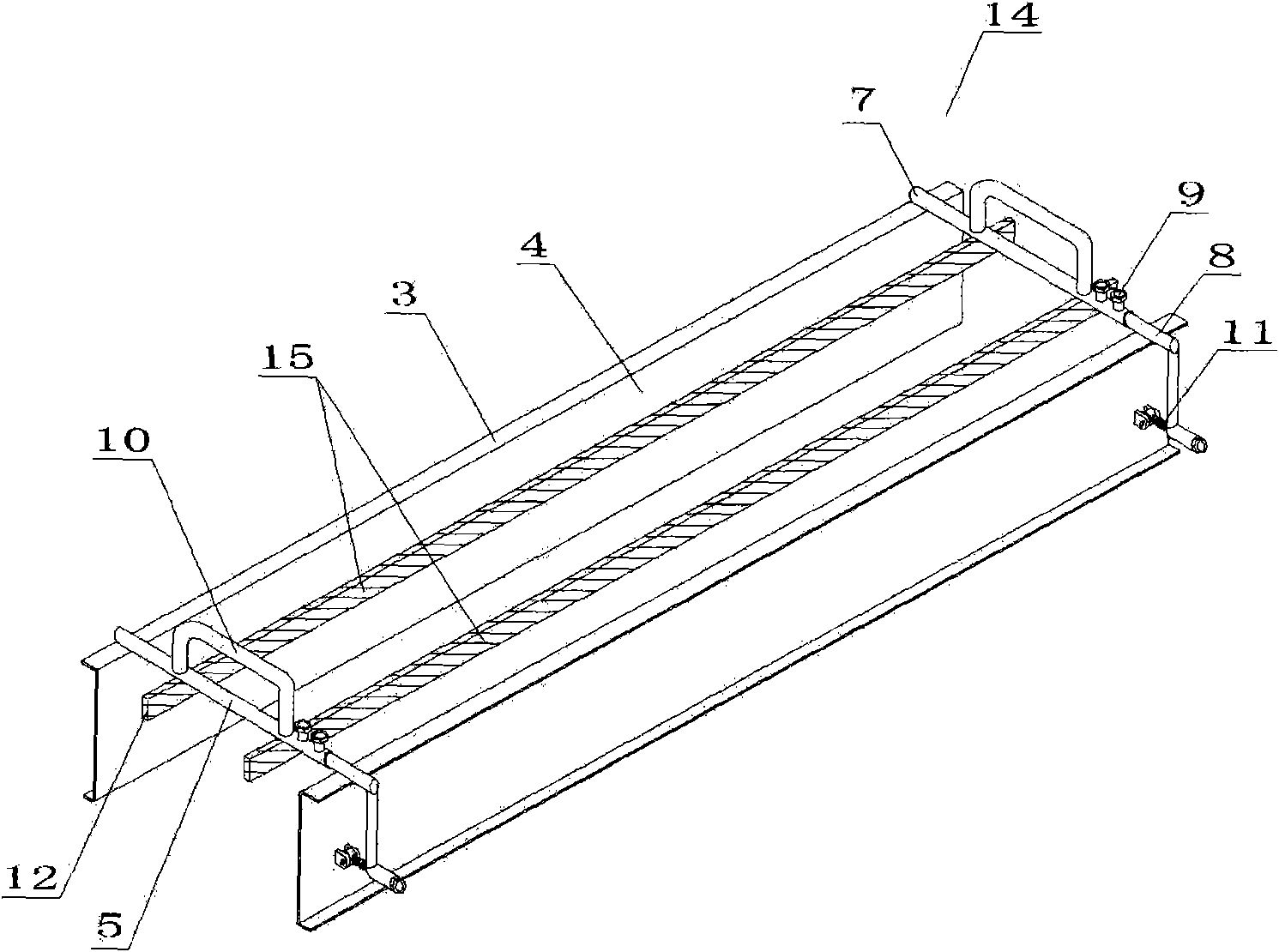

[0034] Technical scheme of the present invention figure 2 The grouting device 13 of the dot-shaped thickness gauge is connected by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com