High-wear-resistant artificial leather and preparation method thereof

A kind of artificial leather and wear-resistant technology, which is applied in the direction of textiles and papermaking, and can solve the problems of poor stain resistance, poor impact resistance, and poor wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

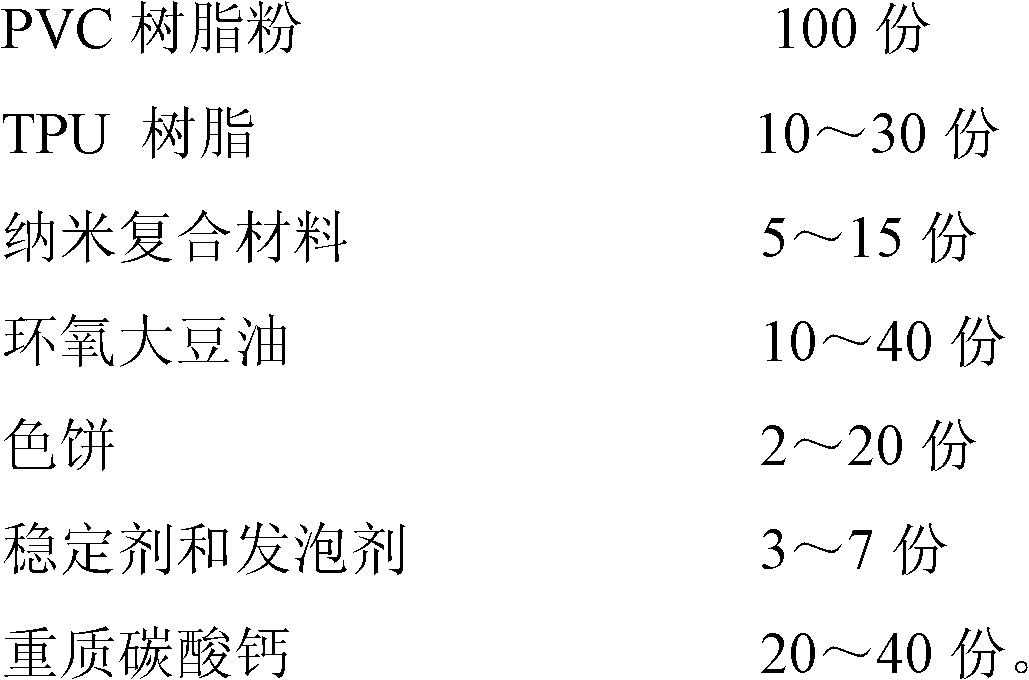

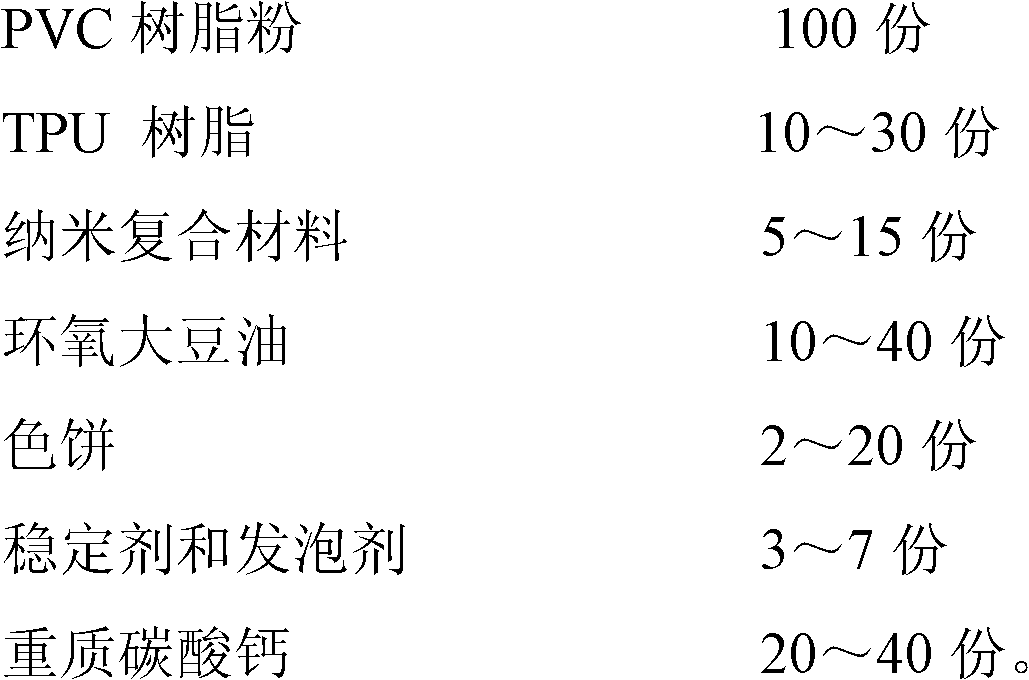

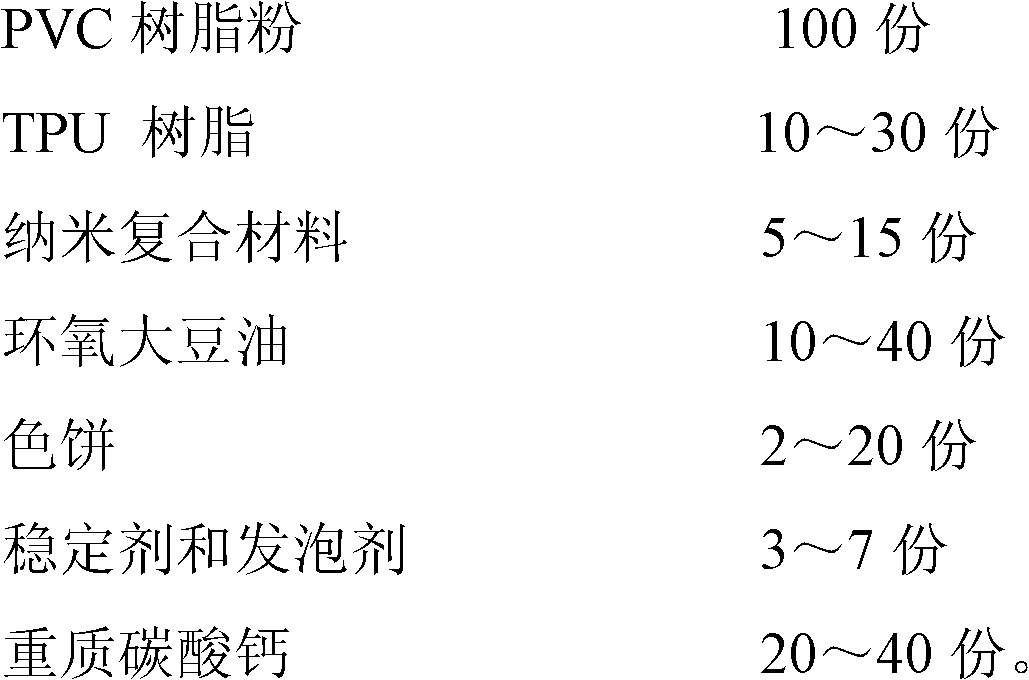

[0020] The raw materials of the high wear-resistant slurry and their weight ratios are: 100 parts of PVC resin powder, 25 parts of TPU resin, nano-alumina and nano-silica composite material (1:1, average particle size 20nm; specific surface area ≥ 50m / g) 14 parts, 30 parts of epoxy soybean oil, 7 parts of color cake, 2 parts of potassium zinc stabilizer, 2 parts of foaming agent, 30 parts of heavy calcium.

[0021] According to the ingredients, the above-mentioned materials measured are input into the high-speed mixer through the pulse feeder, and the temperature is controlled at 100-150 ° C. After fully stirring, they enter the internal mixer, and the temperature is controlled at (160 ° C) for several minutes; After the base material (various fabrics) is opened, apply PU slurry (150°C), combine the fully mixed material with the base material with PU slurry, enter the second rolling mill (160°C) for kneading, and then After entering the four-roll calender (temperature 160-190°...

Embodiment 2

[0024] The raw materials of the high wear-resistant slurry and their weight ratios are: 100 parts of PVC resin powder, 15 parts of TPU resin, nano-alumina and nano-silica composite material (1:2, average particle size 20nm; specific surface area ≥ 50m / g) 8 parts, 20 parts of epoxy soybean oil, 15 parts of color cake, 1 part of barium zinc stabilizer, 3 parts of azodicarbonamide, 20 parts of heavy calcium.

[0025] According to the ingredients, the above-mentioned materials measured are input into the high-speed mixer through the pulse feeder, and the temperature is controlled at 100-150 ° C. After fully stirring, they enter the internal mixer, and the temperature is controlled at (160 ° C) for several minutes; After the base material (various fabrics) is opened, apply PU slurry (150°C), combine the fully mixed material with the base material with PU slurry, enter the second rolling mill (160°C) for kneading, and then After entering the four-roll calender (temperature 160-190°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com