Delustring medical soft PVC modified material with low temperature resistance and low DOP precipitation

A modified material and low-temperature-resistant technology, which is applied in the field of matting medical soft PVC modified materials, can solve the problems of low-temperature flexibility, sticky surface, and large plasticizer precipitation, etc., achieve excellent precipitation resistance, improve matting performance, The effect of excellent low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

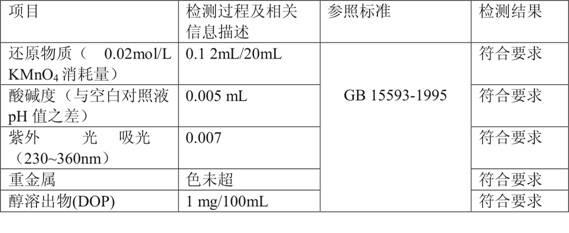

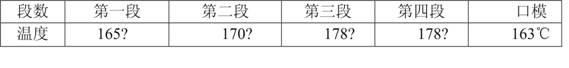

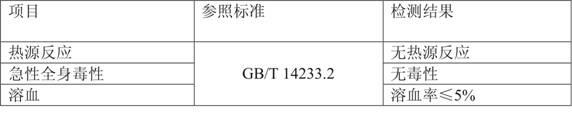

Examples

Embodiment 1

[0028] Matting resin powder (polymerization degree 1000~1500, gel content 19.0%~25.0%) 35 parts

[0029] Ordinary resin powder (polymerization degree 1000~1800) 65 parts

[0030] ACR-201 2 parts

[0031] Plasticizer: DOP 60 parts

[0032] Liquid Calcium Zinc 0.9 parts

[0033] Tris(nonylphenyl) phosphite 0.3 parts

[0034] Auxiliary stabilizer: 4 parts of epoxy soybean oil

[0035] Oxidized polyethylene wax 0.2 parts

[0036] The preparation method is as follows:

[0037] Mixing: Add PVC resin powder, ACR and stabilizer to the high-speed mixer at low speed. The low-speed operation speed is 441rpm; when the temperature reaches 65°C, add DOP, antioxidant, epoxy soybean oil, and turn to high speed after 1.5min. , the high-speed operation speed is 877rpm; when the temperature reaches 110°C, add lubricant, continue to stir until 145°C and discharge the material to the cold pot until the temperature of the material reaches about 30°C;

[0038] Granulation: use SJSZ-65 twin-sc...

Embodiment 2

[0043] Matting resin powder (polymerization degree 1000~1500, gel content 19.0%~25.0%) 20 parts

[0044] Ordinary resin powder (polymerization degree 1000~1800) 80 parts

[0045] Plasticizer: DOP 20 parts

[0046] Liquid calcium zinc 0.8 part

[0047] Tris(nonylphenyl) phosphite 0.2 parts

[0048] Auxiliary stabilizer: epoxy soybean oil 1 part

[0049] Oxidized polyethylene wax 0.2 parts

[0050] The preparation method is as in Example 1.

Embodiment 3

[0052] Matting resin powder (polymerization degree 1000~1500, gel content 19.0%~25.0%) 80 parts

[0053]Ordinary resin powder (polymerization degree 1000~1800) 20 parts

[0054] ACR-201 5 copies

[0055] Plasticizer: DOP 80 parts

[0056] Liquid Calcium Zinc 3 parts

[0057] Phosphite tris(nonylphenyl ester) 1.5 parts

[0058] Auxiliary stabilizer: 6 parts of epoxy soybean oil

[0059] Oxidized polyethylene wax 0.8 parts

[0060] The preparation method is as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com