Diacetyl epoxy glyceryl oleates and synthesis method thereof

A technology of diacetyl epoxy and vegetable oleic acid, which is applied in the synthesis of plasticizers. In the field of synthetic plasticizers, it can solve the problems of high viscosity, poor fluidity, and low molecular weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]Soybean oil is used as the basic raw material. As can be seen from Table 1: soybean oil belongs to tri-fatty acid glycerides, the main component is eighteen carbon fatty acids, and the others are C 14 -C 20 range of some fatty acids.

[0040] The composition of raw soybean oil fatty acid is as follows:

[0041]

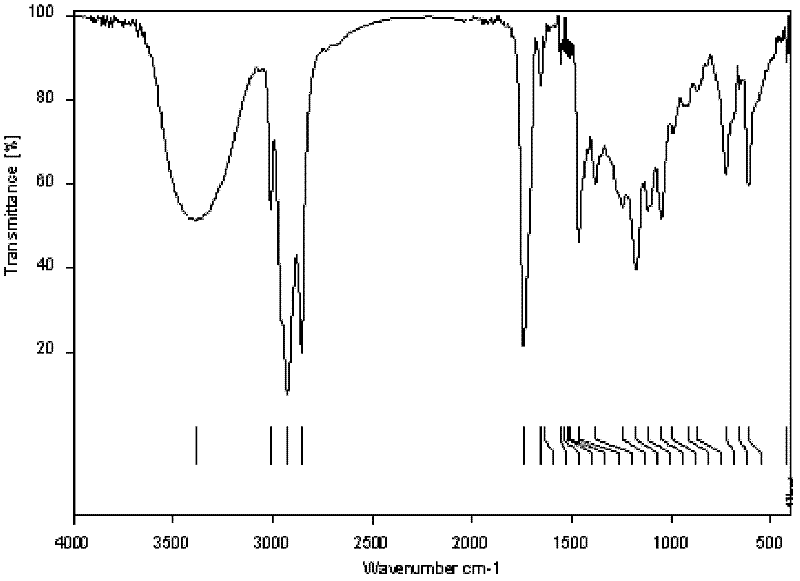

[0042] Transesterification: Add 838g soybean oil and 162g glycerol into a three-necked round-bottomed flask with a stirring device, a thermometer and a reflux condenser in turn, introduce nitrogen and stir to heat up, when the temperature reaches 120°C, add a calcium oxide catalyst 0.2 g, the reaction was incubated at 200°C for 2 hours. The material was taken intermittently, and the reaction was terminated when 1 part of the sample was dissolved in 10 parts of ethanol. Soybean monoglyceride was obtained as a pale yellow oil. Infrared spectroscopy, such as figure 1 shown, IR(KBr): 3383cm- 1 Broad peak is -OH peak, 3009cm- 1 C-H stretching vibration abs...

Embodiment 2

[0046] Soybean oil is used as the basic raw material.

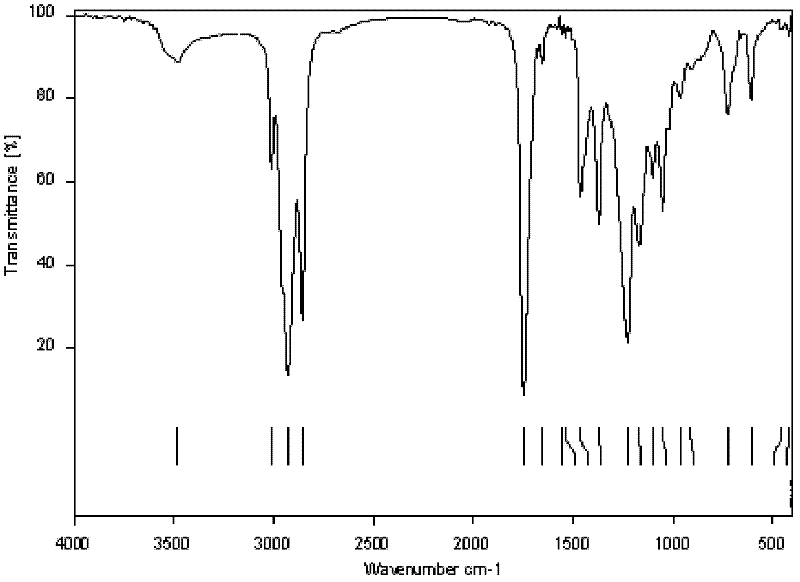

[0047] Transesterification: Add 100g soybean oil and 20.2g glycerol in turn to a three-necked round-bottomed flask with a stirring device, a thermometer and a reflux condenser, introduce nitrogen and stir to heat up, when the temperature reaches 120 °C, add sodium hydroxide 0.02 g of catalyst was incubated at 200°C for 4 hours. The material was taken intermittently, and the reaction was terminated when 1 part of the sample was dissolved in 10 parts of ethanol. A light yellow oily monoglyceride of soybean oleate was obtained. Infrared spectrum measurement, IR (KBr): 3385cm- 1 Broad peak is -OH peak, 3009cm- 1 C-H stretching vibration absorption of unsaturated hydrocarbons; 2926cm- 1 C-H asymmetric stretching vibration absorption of saturated hydrocarbon CH2; 2854cm- 1 is the C-H symmetrical stretching vibration absorption of saturated hydrocarbon CH2; 1741cm- 1 C=O stretching vibration absorption of ester; 1464cm- 1...

Embodiment 3

[0051] Using rice bran oil as the basic raw material, rice bran oil is the same as soybean oil, and its main component is triglyceride. Its fatty acid composition is 40-50% of oleic acid, 29-42% of linoleic acid, and 12-18% of palmitic acid. The average molecular weight of fatty acids is 278-285, and the iodine value is 98-110.

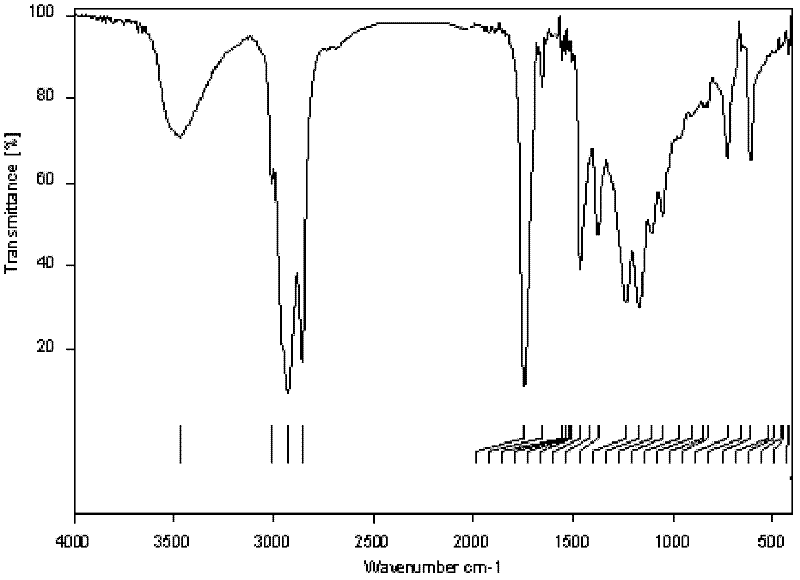

[0052] Transesterification: Add 100g of rice bran oil and 20.2g of glycerol to a three-necked round-bottomed flask with a stirring device, a thermometer and a reflux condenser in turn, and then introduce nitrogen and stir to heat up. When the temperature reaches 120°C, add sodium hydroxide. 0.02 g of catalyst was incubated at 200°C for 4 hours. The material was taken intermittently, and the reaction was terminated when 1 part of the sample was dissolved in 10 parts of ethanol. Obtained a light yellow oily monoglyceride of rice bran oleate. Infrared spectroscopy, such as Figure 4 shown, IR(KBr): 3415cm- 1 Broad peak is -OH peak, 3008cm- 1 C-H st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com