Cold-resistant oilproof flame-retardant PVC (Polyvinyl Chloride) cable material and preparation method thereof

A flame-retardant polyvinyl chloride and cable material technology, which is applied in the direction of insulating cables, cables, circuits, etc., can solve the problems that the small molecules of plasticizers cannot be inserted, the application of cable materials is limited, and the cold resistance of plasticizers is not enough. Achieve excellent durability and thermal stability, chemical resistance without migration, improve cold resistance and migration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

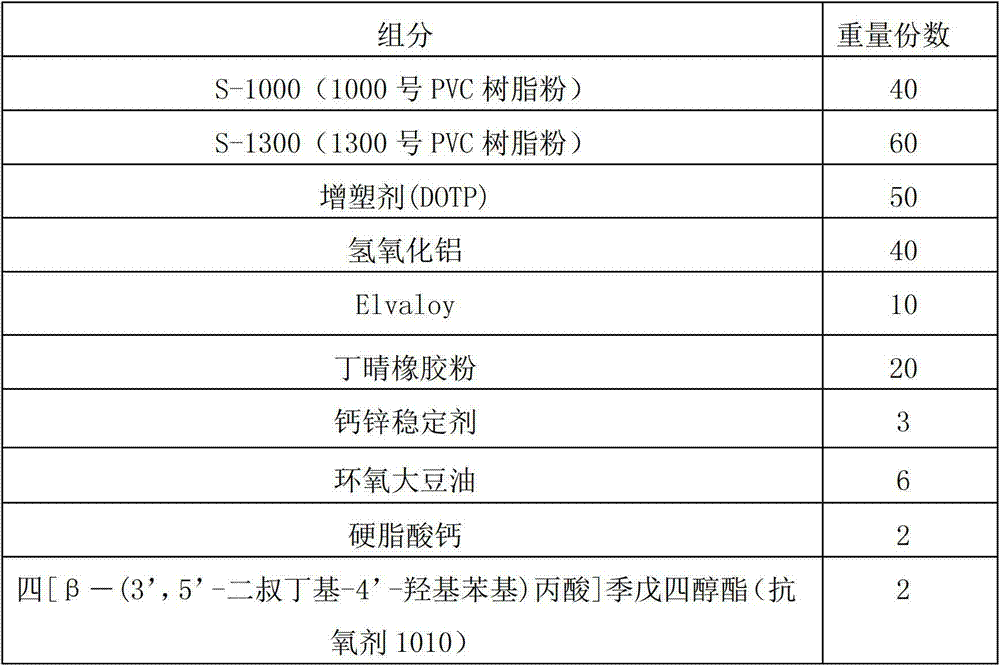

[0019] This embodiment is a kind of cold-resistant, oil-resistant and flame-retardant polyvinyl chloride cable material:

[0020] (1) Raw material formula:

[0021] As shown in the following table:

[0022]

[0023] (2) Preparation process:

[0024] Stir PVC resin powder, plasticizer, nitrile rubber powder, stabilizer, epoxy soybean oil, flame retardant, Elvaloy, antioxidant and lubricant in a high-speed mixer first, and then mix them at a temperature of 120°C In the lower section, it is internally mixed with an internal mixer, extruded by a twin-screw, ground and granulated, fed by a cyclone separator, screened by a vibrating sieve and then packaged to form a finished product of cold-resistant, oil-resistant, and flame-retardant PVC cable material.

[0025] (3) Material properties:

[0026] The cold-resistant, oil-resistant and flame-retardant PVC cable material prepared according to the above formula and process has the following properties: tensile strength 17MPa, elo...

Embodiment 2

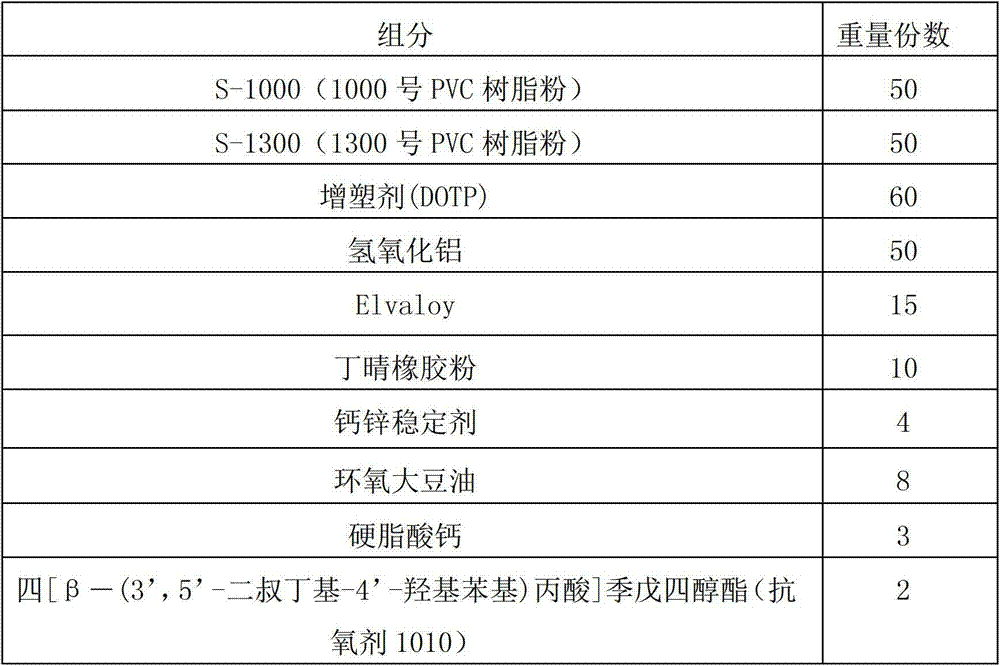

[0028] This embodiment is a kind of cold-resistant, oil-resistant and flame-retardant polyvinyl chloride cable material:

[0029] (1) Raw material formula:

[0030] As shown in the following table:

[0031]

[0032] (2) Preparation process:

[0033] Stir PVC resin powder, plasticizer, nitrile rubber powder, stabilizer, epoxy soybean oil, flame retardant, Elvaloy, antioxidant and lubricant in a high-speed mixer, and then mix them at a temperature of 130°C In the lower section, it is internally mixed with an internal mixer, extruded by a twin-screw, ground and granulated, fed by a cyclone separator, screened by a vibrating sieve and then packaged to form a finished product of cold-resistant, oil-resistant, and flame-retardant PVC cable material.

[0034] (3) Material properties:

[0035] The cold-resistant, oil-resistant and flame-retardant polyvinyl chloride cable material prepared according to the above formula and process has the following properties: tensile strength 1...

Embodiment 3

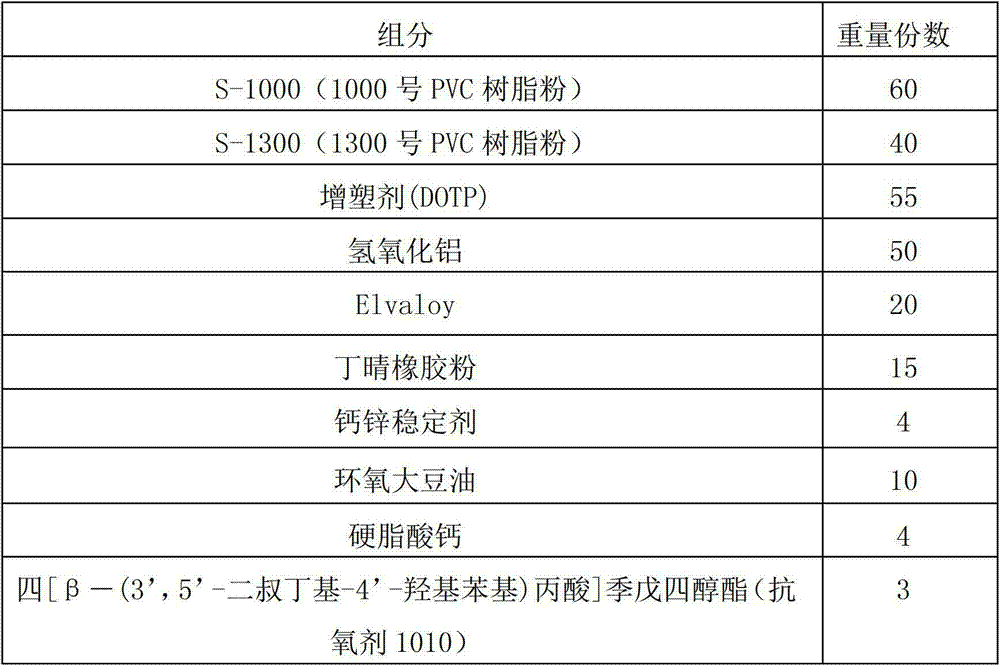

[0037] This embodiment is a kind of cold-resistant, oil-resistant and flame-retardant polyvinyl chloride cable material:

[0038] (1) Raw material formula:

[0039] As shown in the following table:

[0040]

[0041] (2) Preparation process:

[0042] Stir PVC resin powder, plasticizer, nitrile rubber powder, stabilizer, epoxy soybean oil, flame retardant, Elvaloy, antioxidant and lubricant in a high-speed mixer, and then mix them at a temperature of 140°C In the lower section, it is internally mixed with an internal mixer, extruded by a twin-screw, ground and granulated, fed by a cyclone separator, screened by a vibrating sieve and then packaged to form a finished product of cold-resistant, oil-resistant, and flame-retardant PVC cable material.

[0043] (3) Material properties: The cold-resistant, oil-resistant and flame-retardant PVC cable material prepared according to the above formula and process has the following properties: tensile strength 18MPa, elongation at break...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com