Organosilicone modification polyurethane color fixing agent and preparation method thereof

A technology of polyurethane and color-fixing agent, which is applied in fiber treatment, textiles and papermaking, etc. It can solve the problems of poor color fastness to washing and poor water resistance, etc., so as to improve rough hand feeling, increase cross-linking property, and increase film-forming property Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 6 parts of hydroxy silicone oil 400 and 60 parts of polypropylene glycol 600 into the reaction vessel, remove water for 1 hour at a temperature of 110°C and a vacuum of -0.05MPa; cool down to 75°C, and add 0.1 part of dibutylene after nitrogen gas for 0.5h Base tin laurate, start to add 43 parts of isophorone diisocyanate dropwise, keep warm at 80°C for 3h after the dropwise addition; cool down to 50°C, add 1 part of trihydroxypropane, and slowly add 10 parts of N-formazol Diethanolamine and 30 parts of acetone, the dropwise addition time is 1.5 hours, and after the addition, it is kept at 45°C for 2 hours; 6 parts of methyl ethyl ketone oxime is added, and the capping reaction is carried out at 50°C for 2 hours, and then 5 parts of acetic acid is added to neutralize 0.5 h, finally add 480 parts of deionized water and stir at high speed, remove acetone under reduced pressure at 50°C to obtain a silicone-modified polyurethane color fixing agent.

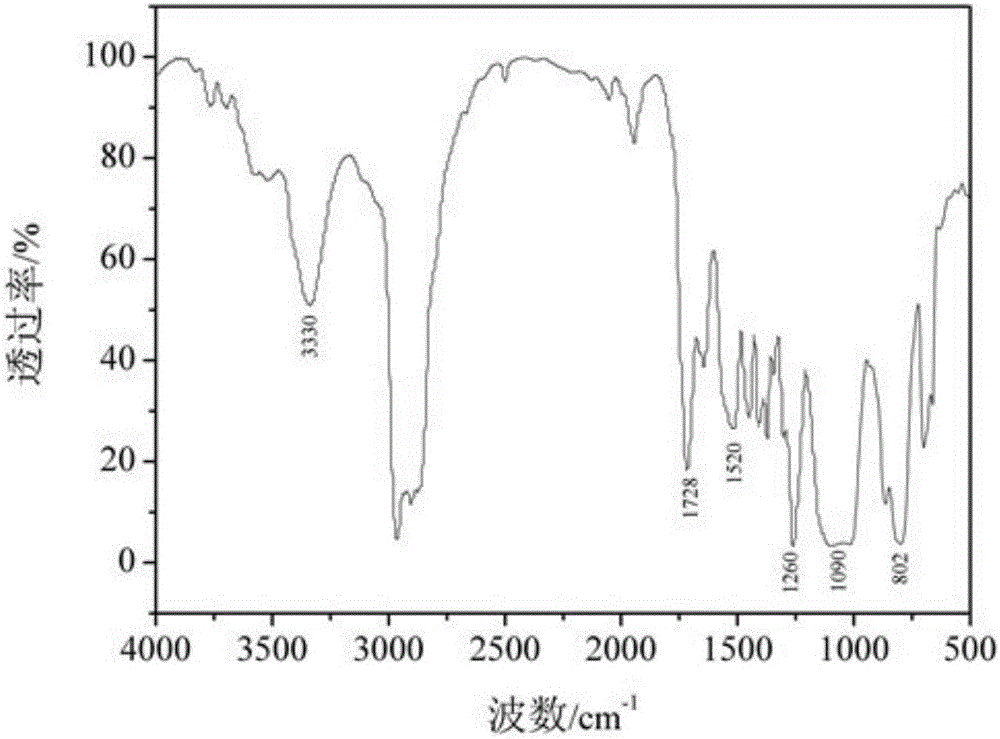

[0024] See attached...

Embodiment 2

[0026] Add 5 parts of hydroxy silicone oil 800 and 48 parts of polypropylene glycol 600 into the reaction vessel, remove water for 1 hour at a temperature of 110°C and a vacuum of -0.05MPa; cool down to 75°C, and add 0.1 part of dibutylene after nitrogen gas for 0.5h Base tin laurate, start to add 35 parts of isophorone diisocyanate dropwise, keep warm at 80°C for 4h after the dropwise addition; cool down to 50°C, add 1 part of trihydroxypropane, and slowly add 8 parts of N-methyl Diethanolamine and 25 parts of acetone, the dropwise addition time is 1h, after the addition, keep warm at 50°C for 2h; add 5 parts of methyl ethyl ketone oxime, 50°C for 2h, then add 4 parts of acetic acid to neutralize for 0.5h , and finally add 400 parts of deionized water and stir at high speed, and remove acetone under reduced pressure at 50°C to obtain a silicone-modified polyurethane color fixing agent.

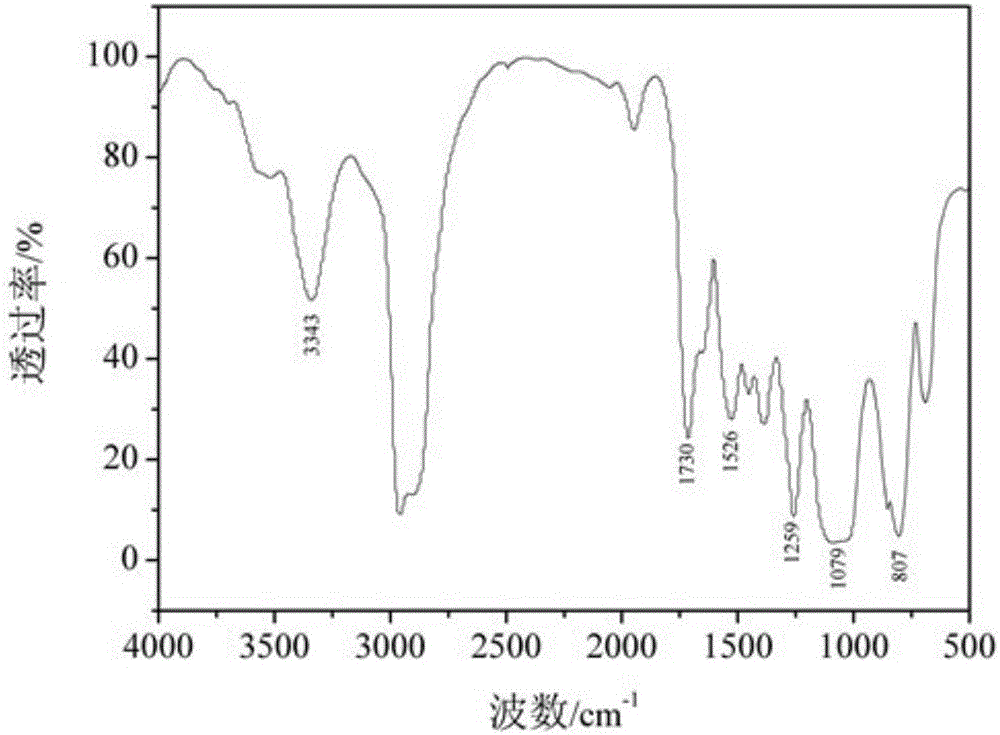

[0027] See attached figure 2 , which is the infrared spectrum of the silicone-modified ...

Embodiment 3

[0029] Add 4 parts of hydroxy silicone oil 800 and 60 parts of polypropylene glycol 600 into the reaction vessel, remove water for 1 hour at a temperature of 110°C and a vacuum of -0.06MPa; cool down to 75°C, and add 0.2 parts of dibutylene after nitrogen gas for 0.5h Base tin laurate, start to add 40 parts of isophorone diisocyanate dropwise, keep warm at 82°C for 3 hours after the dropwise addition; cool down to 50°C, add 1 part of trihydroxypropane, and slowly add 10 parts of N-methyl Diethanolamine and 30 parts of acetone, the dropwise addition time is 1.5 hours, after the addition, keep warm at 50°C for 2 hours; add 3 parts of methyl ethyl ketone oxime, 50°C capping reaction for 1.5 hours, then add 5 parts of acetic acid to neutralize After 0.5h, add 460 parts of deionized water and stir at high speed, and remove acetone under reduced pressure at 50°C to obtain a silicone-modified polyurethane color fixing agent.

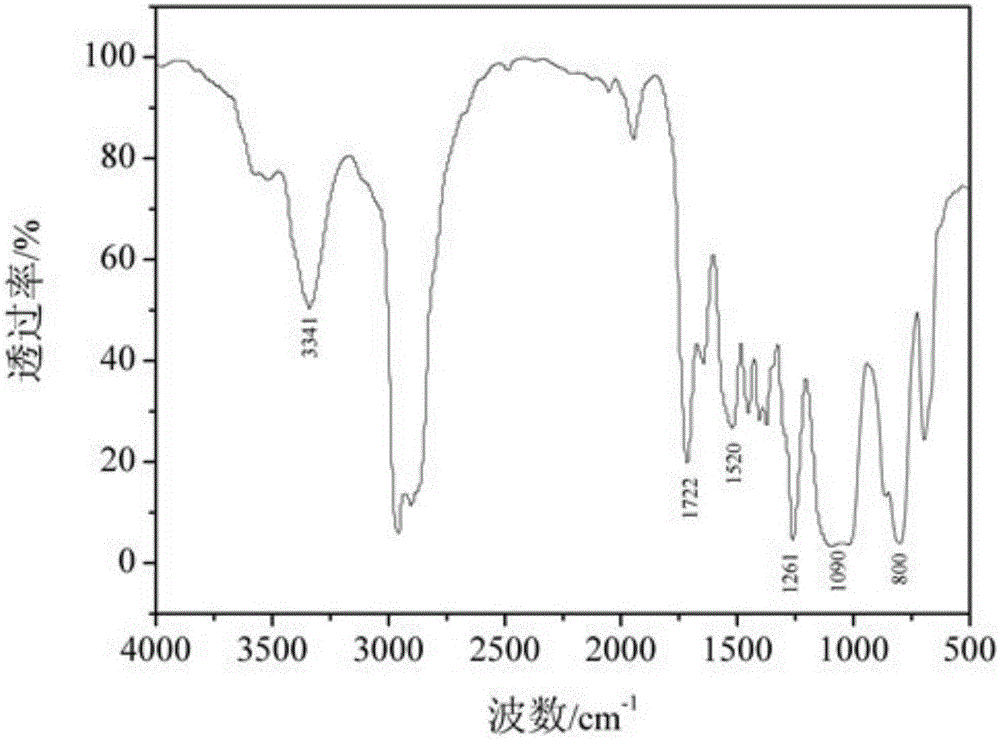

[0030] See attached image 3 , which is the infrared spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com