Process for preparing titanium dioxide with high weatherability

A technology of titanium dioxide and weather resistance, which is applied in the direction of chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems that the weather resistance of titanium dioxide cannot be improved, and achieve the effect of improving the weather resistance index and increasing the deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

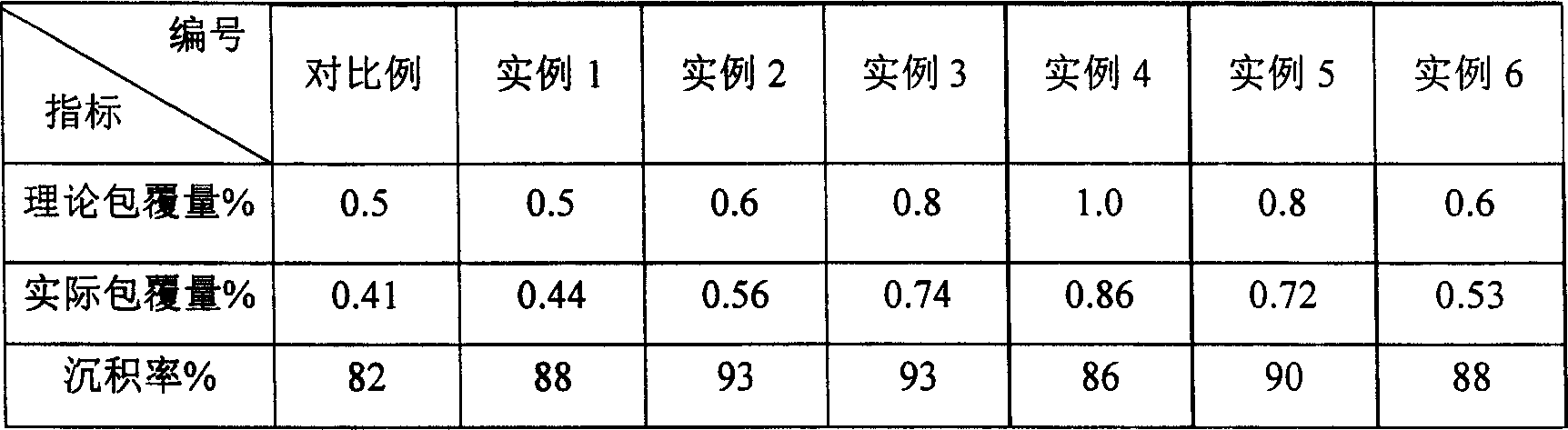

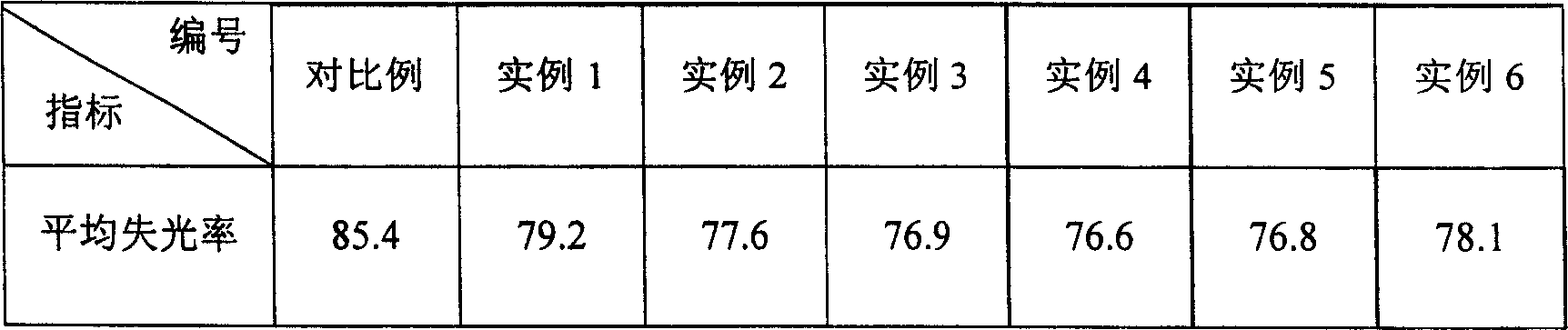

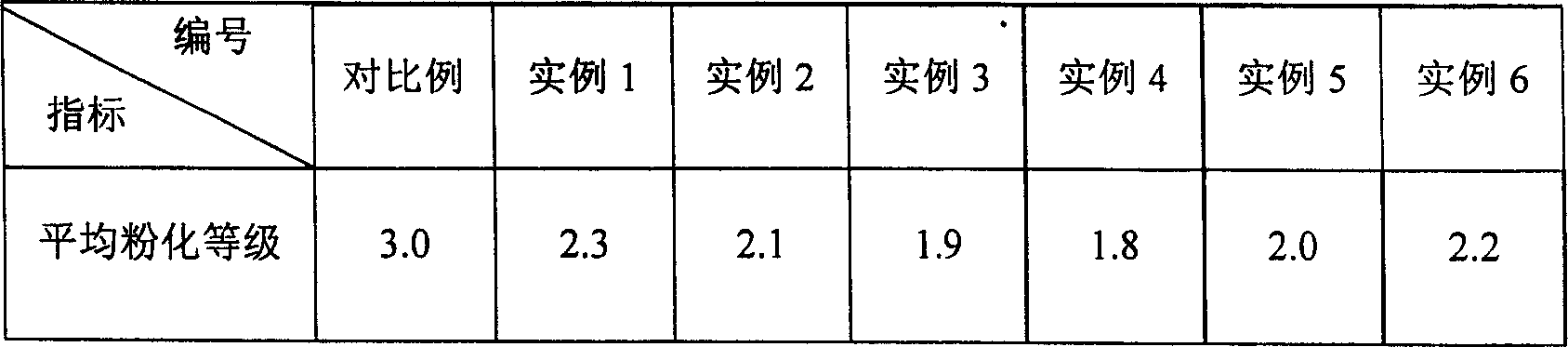

Examples

example 1

[0011] Get 700g of sulfuric acid method rutile type titanium dioxide without surface treatment, add deionized water to make a slurry with a concentration of about 700g / l, add 14ml sodium hexametaphosphate solution (concentration is based on P 2 o 5 Calculated at 50g / l, the amount added is based on TiO 2 0.1% in total), 1.48ml of isopropanolamine (content 98%, density: 0.9650g / ml, the amount added is based on TiO 2 0.2% in total) as a dispersant, and dispersed for 60 minutes at a speed of 3000 rpm on a high-speed disperser. Add a certain amount of deionized water to the dispersed slurry and dilute to 300g / l, get 1000ml of it, heat up to 50°C, adjust PH=5.0 with dilute sulfuric acid solution (concentration is 10%, w / w), in Under this pH condition, add 15ml zirconium sulfate solution simultaneously (the concentration of zirconium sulfate is based on ZrO 2 Calculated at 100g / l, the amount added is based on TiO 2 0.5%) and sodium hydroxide solution, the time is 20 minutes, at p...

example 2

[0013] Get 700g of sulfuric acid method rutile type titanium dioxide without surface treatment, add deionized water to make a slurry with a concentration of about 700g / l, add 28ml sodium hexametaphosphate solution (concentration is based on P 2 o 5 Calculated at 50g / l, the amount added is based on TiO 2 0.2%), 0.74ml isopropanolamine (content 98%, density: 0.9650g / ml, the amount added is based on TiO 2 0.1% in total) as a dispersant, and dispersed for 60 minutes at a speed of 3000 rpm on a high-speed disperser. Add a certain amount of deionized water to the dispersed slurry and dilute to 300g / l, get 1000ml of it, heat up to 55°C, adjust pH=4.5 with dilute sulfuric acid solution (concentration is 10%, w / w), and Under this pH condition, add 18ml zirconium sulfate solution simultaneously (the concentration of zirconium sulfate is based on ZrO 2 Calculated at 100g / l, the amount added is based on TiO 2 0.6%) and sodium hydroxide solution, the time is 20 minutes, at pH=4.5 aging...

example 3

[0015] Get 700g of sulfuric acid method rutile type titanium dioxide without surface treatment, add deionized water to make a slurry with a concentration of about 700g / l, add 42ml sodium hexametaphosphate solution (concentration is based on P 2 o 5 Calculated at 50g / l, the amount added is based on TiO 2 0.3%), 1.48ml isopropanolamine (content 98%, density: 0.9650g / ml, the amount added is based on TiO 2 0.2% in total) as a dispersant, and dispersed for 60 minutes at a speed of 3000 rpm on a high-speed disperser. Add a certain amount of deionized water to the dispersed slurry and dilute to 200g / l, get 1000ml of it, heat up to 55°C, adjust pH=4.0 with dilute sulfuric acid solution (concentration is 10%, w / w), and Under this pH condition, add 16ml zirconium sulfate solution simultaneously (the concentration of zirconium sulfate is based on ZrO 2 Calculated at 100g / l, the amount added is based on TiO 2 0.8%) and sodium hydroxide solution, the time is 30 minutes, at pH=4.0 aging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com