Golf Balls Including A Crosslinked Thermoplastic Polyurethane Cover Layer Having Improved Scuff Resistance

a thermoplastic polyurethane and golf ball technology, applied in the field of golf balls, can solve the problems of poor scuff resistance of ionomer resin-covered golf balls, cover surface scraping, and poor scuff resistance of ionomer covers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

examples

[0086]Two golf balls in accordance with the present disclosure were fabricated as described below, and their scuff resistance was compared to several comparative examples.

[0087]For each golf ball, the core was made from a material selected from Table 1, and the cover layer was made from a material selected from Table 2. The amount of the materials listed in Tables 1 and 2 is shown in parts by weight (pbw) or percentages by weight.

TABLE 1Core MaterialsRubber compound:ABTAIPOL ™ BR0150*100100Zinc diacrylate2825Zinc oxide55Barium sulfate1618Peroxide11

[0088]TAIPOL™ BRO150 is the trade name of a rubber produced by Taiwan Synthetic Rubber Corp.

TABLE 2Cover MaterialsCDEFGHIPTMEG (pbw)100 100 100100BG (pbw)15 15 1515TMPME 10% 10%010%(weight %to totalcomponents)DCP0.2%0.5%00(weight %to totalcomponents)MDI (pbw)87.887.855.087.8(NCO index) 1.01 1.011.011.01Texin ® 245100Elastollan ®1001195ASurlyn ® 894050Surlyn ® 991050

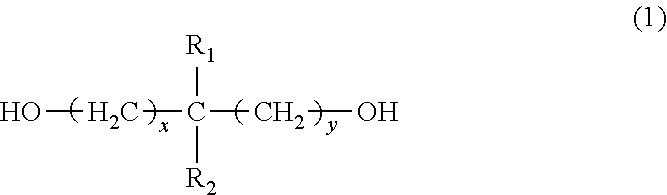

[0089]“PTMEG” is polytetramethylene ether glycol, having a number avera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com