Low temperature fireable paste composition for forming an electrode or wiring

一种组合物、电极的技术,应用在印刷元件电连接形成、分散在不导电无机材料中的导电材料、电路等方向,能够解决难以实现高分辨率电极图案、降低Ag粒子密合性和熔接性、缓慢固化速度等问题,达到优异电阻率特性、印刷特性优异、固化度优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3、 and comparative example 1 and 2

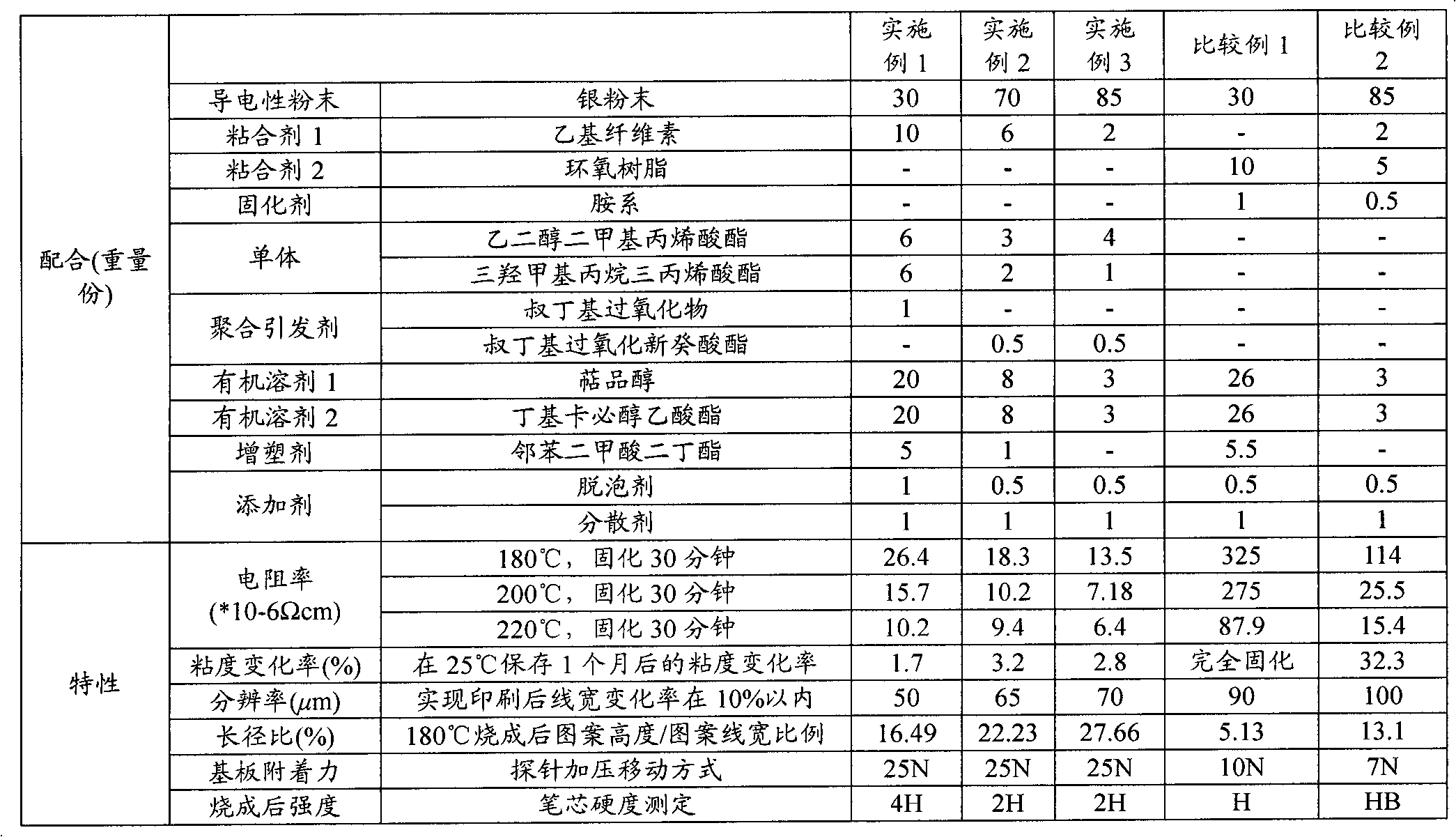

[0047] The components described in the following Table 1 were used in corresponding amounts, and were mixed with a three-roll kneader to manufacture the target paste composition.

[0048] Next, resistivity, viscosity change, resolution, aspect ratio, substrate adhesion, strength after firing, etc. were measured for the produced paste composition, and the physical property measurement results are also shown in Table 1.

[0049] Table 1

[0050]

[0051] As can be seen from the above Table 1, the paste compositions of the present invention produced in Examples 1 to 3, compared with the compositions produced in Comparative Examples 1 and 2, not only exhibit significantly superior resistivity characteristics, stability, strength and Substrate adhesion, high resolution and high aspect ratio electrode patterns can also be achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com