Void-containing resin molded product, process for producing the void-containing resin molded product, and image receiving film or sheet for sublimation transfer recording material or thermal transfer

A technology of resin molded body and molded body, applied in the direction of copying/marking method, printing, coating, etc., can solve the problem of increased device cost, etc., and achieve the effect of excellent printing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

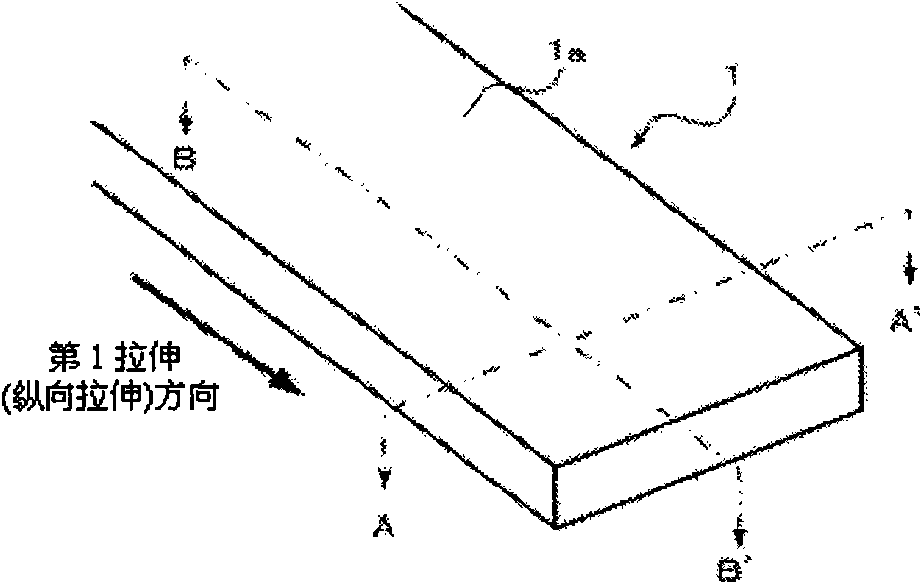

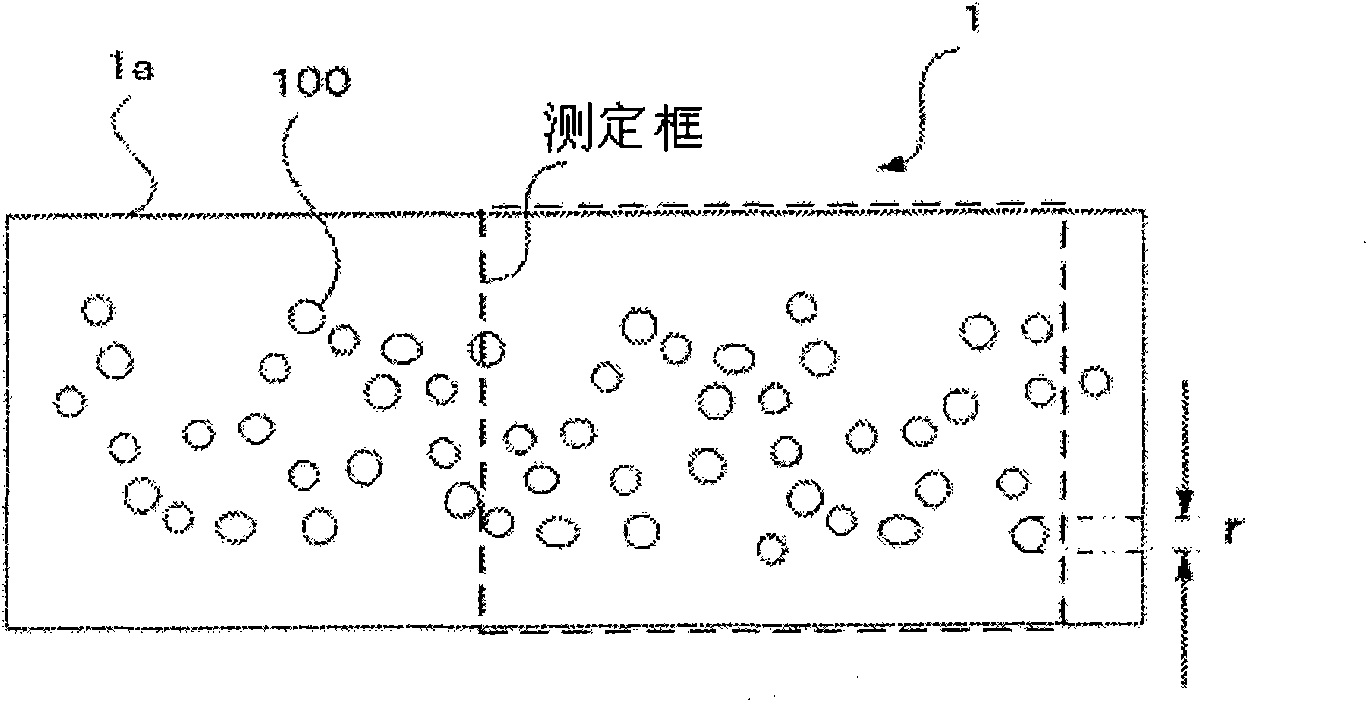

[0085] In the production process of the void-containing resin molded body, the voids are usually oriented in the first stretching direction. Therefore, the "average length (r (μm)) of the voids in the thickness direction perpendicular to the orientation direction of the voids" corresponds to being perpendicular to the surface 1a of the resin molded body 1 containing voids and to the first A cross-section at right angles to the stretching direction ( Figure 2A The average thickness r of the cavity 100 in the A-A' cross section in Figure 2B ). In addition, "the average length of the voids in the orientation direction of the voids (L (μm))" corresponds to a length perpendicular to the surface of the void-containing resin molded article and parallel to the first stretching direction. Parallel sections ( Figure 2A The average length L of the cavity 100 in the B-B' profile in Figure 2C ).

[0086] It should be noted that the first stretching direction means a unidirectional...

Embodiment 1

[0138] Using a melt extruder, extrude PBT1 (polybutylene terephthalate 100% resin) with IV=0.72 at 245°C from a T-die, pass it through a casting drum and solidify it to obtain a polymer film with a thickness of about 120 µm . This polymer film is uniaxially stretched (longitudinal stretch).

[0139] Specifically, uniaxially stretched at a rate of 100 mm / min in a warming atmosphere at 40°C, and after confirming that necking occurs, further uniaxially stretched at a rate of 6000 mm / min in the same direction as the first .

Embodiment 2

[0141] In Example 1, the stretching temperature was set at 30° C., the thickness of the polymer film was about 50 μm, and the longitudinal stretching speed in the second stage was changed from 6000 mm / min to 12000 mm / min for stretching. In addition, A resin film was prepared in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com