Thermal printing head, manufacturing method thereof and thermal printer

A technology of a thermal print head and a manufacturing method, applied in directions such as printing, can solve the problems of electrode short circuit, printing efficiency reduction of printing medium and other printing characteristics, frequent disconnection, etc., and achieve the effect of improving printing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

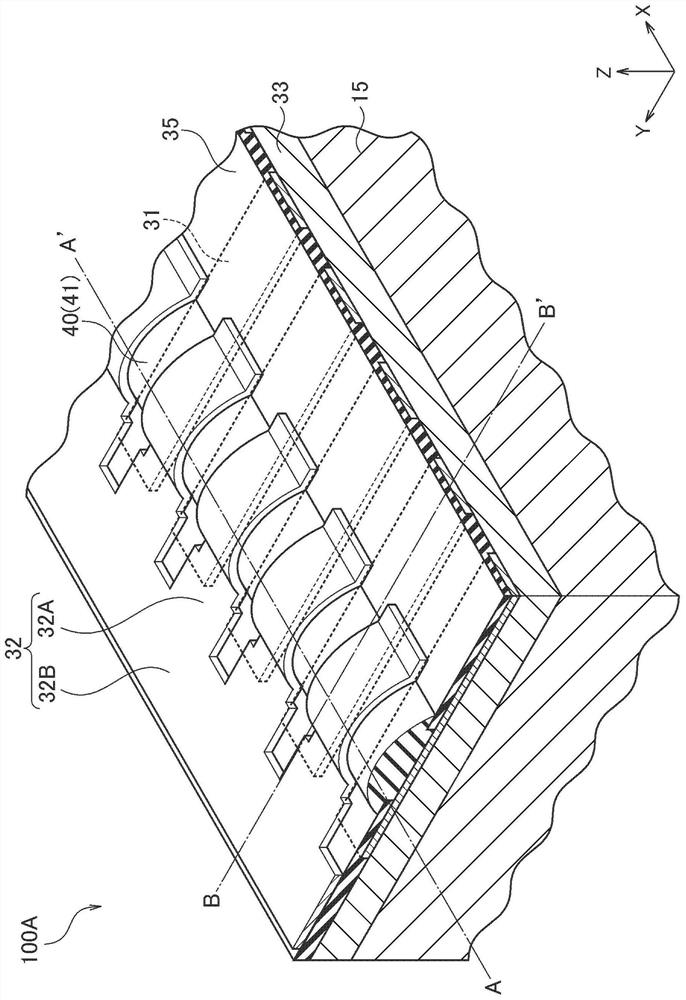

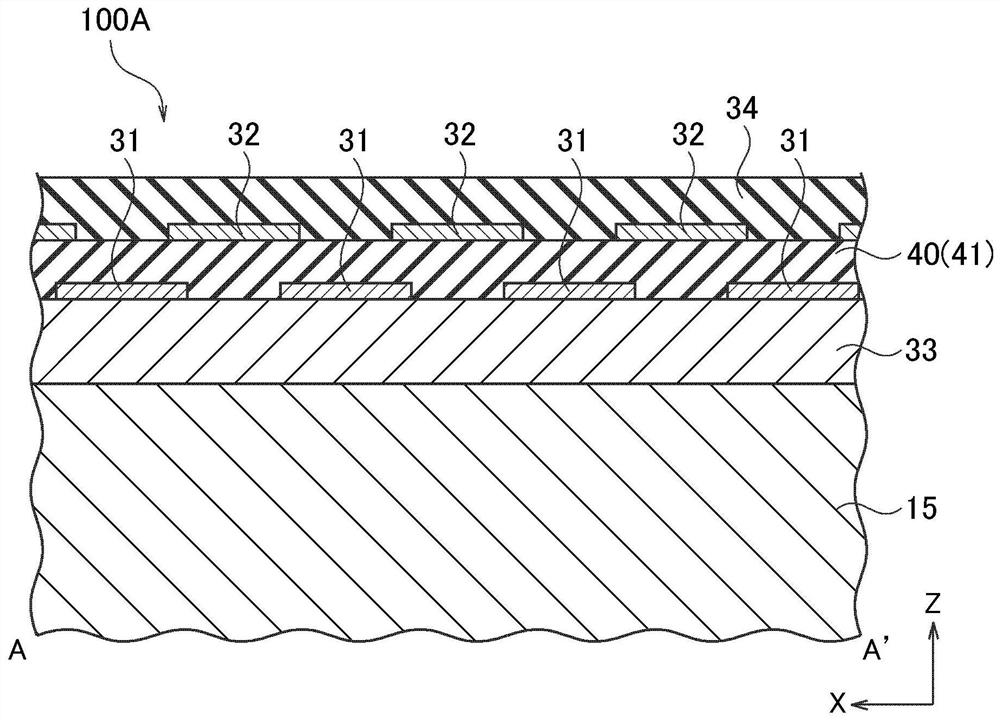

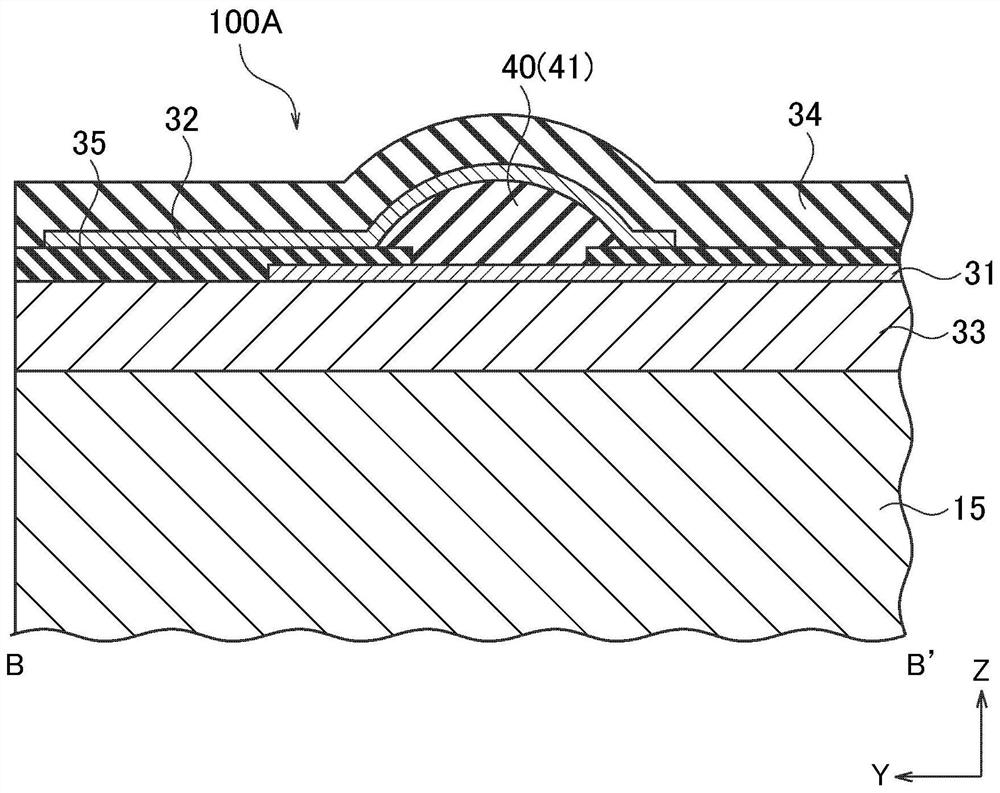

[0106] The thermal printhead according to this embodiment will be described with reference to the drawings.

[0107] figure 1 It is a partial perspective view showing a thermal print head. figure 2 is along the main scanning direction X figure 1 A partial sectional view of the A-A' line. image 3 is along the sub-scanning direction Y figure 1 A partial cross-sectional view of the B-B' line. Figure 1 ~ Figure 3A part of the thermal head (corresponding to one thermal head) is shown, and in this embodiment, this one thermal head is a single-chip thermal head 100A. The thermal printhead 100A includes at least a heat storage layer 33 , a first electrode portion on the heat storage layer 33 , a heat generating resistor 40 on the first electrode portion, a second electrode portion on the heat generating resistor 40 , and an electrode covering the second electrode portion. and the protective film 34 of the heating resistor 40 . Specifically, the thermal print head 100A include...

Embodiment approach 2

[0137] The thermal printhead according to this embodiment will be described with reference to the drawings.

[0138] Figure 19 It is a partial perspective view showing a thermal print head. Figure 20 is along the main scanning direction X Figure 19 A partial sectional view of the A-A' line. Figure 21 is along the sub-scanning direction Y Figure 19 A partial cross-sectional view of the B-B' line. Figure 19 ~ Figure 21 A part of the thermal print head (corresponding to one thermal print head) is shown, and in this embodiment, this one thermal print head is a single-chip thermal print head 100B. The thermal printhead 100B includes at least a heat storage layer 33 , a first electrode portion on the heat storage layer 33 , a heat generating resistor 40 on the first electrode portion, a second electrode portion on the heat generating resistor 40 , and an electrode covering the second electrode portion. and the protective film 34 of the heating resistor 40 . Specifically,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com