Machine and method for producing one or more layers of fibrous webs consisting of cardboard or wrapping paper

A technology of fiber material and wrapping paper, applied in the field of fiber material web machine, can solve the problems of quality loss and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

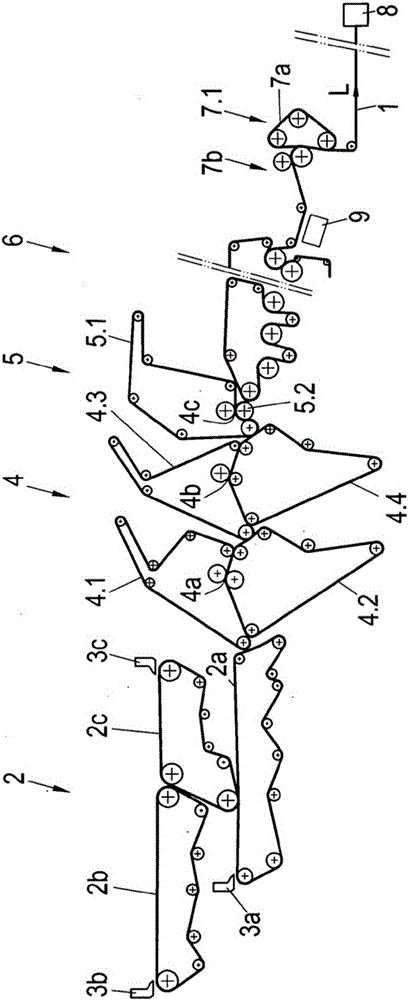

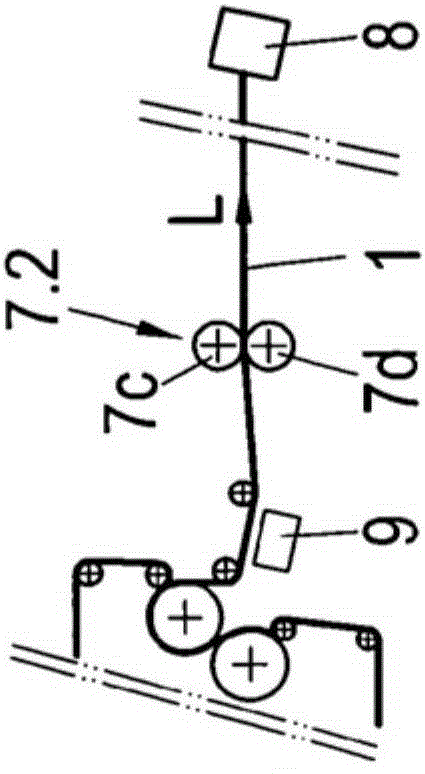

[0029] exist figure 1 In the diagram, a first embodiment of a paper machine for producing a one- or multi-layer fibrous web 1 of cardboard or packaging paper is shown schematically according to the invention.

[0030] The fiber suspension forming the layers of the multilayer web produced afterwards is uniformly distributed in the forming unit 2 over the respectively corresponding forming wires 2a, 2b, 2c via separate headboxes 3a, 3b, 3c, and These are successively joined together to form a multilayer fibrous or cardboard web 1 .

[0031] In the forming unit 2 or wire section, eg white material is processed, which either consists of pulp, white old paper or a combination of white old paper and pulp.

[0032] The forming wire 2a is an elongated wire and transfers the wet fibrous web 1 to a press section 4 having a plurality of separate smoothing nips arranged one behind the other.

[0033] In this embodiment, the fibrous web 1 passes in the machine direction L through three p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com