High-elasticity heat transfer membrane and preparation method thereof

A technology of heat transfer and elasticity, applied in the direction of copying/marking method, temperature recording method, coating, etc., can solve the problems of inability to stretch, inability to cover the surface of the fabric, and broken color layers, so as to improve aesthetics and excellent ease of use. The effect of peelability and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

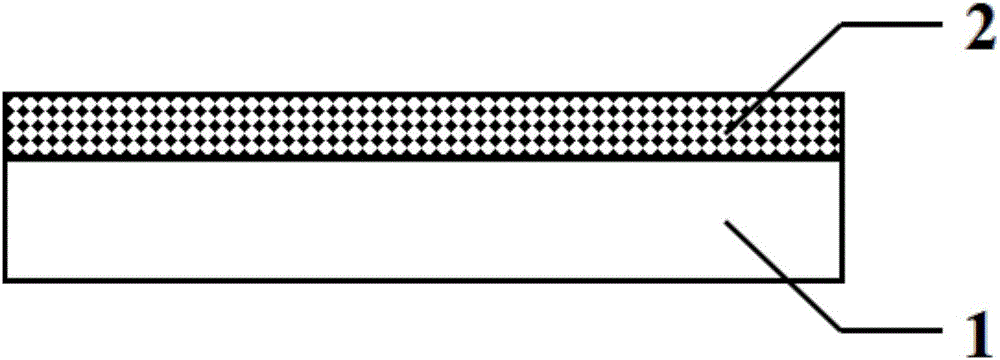

Image

Examples

Embodiment 1

[0021] Embodiment 1 of a preparation method of a high elastic heat transfer film: a preparation method of a high elastic heat transfer film, the preparation steps are as follows

[0022] 1) Use 20μm biaxially oriented polypropylene film as the base film, hereinafter referred to as BOPP base film;

[0023] 2) Coating the surface of the BOPP base film to form an elastic color layer: mix 22% polyurethane resin, 77% methyl ethyl ketone, and 1% accelerator and stir evenly, then add 2% dye and continue stirring evenly to prepare elastic Color layer material, and then apply the above elastic color layer material to the surface of BOPP base film with a 50-mesh screen roller, react and dry in a four-stage oven to form an elastic color layer, in which the highest temperature is 90 °C, and the speed is 45m / min;

[0024] 3) Slitting and winding the elastic film with a slitting machine to obtain the high elastic heat transfer film.

Embodiment 2

[0025] Example 2 of a method for preparing a high-elastic heat transfer film: a method for preparing a high-elastic heat transfer film, the preparation steps are as follows

[0026] 1) A 25 μm biaxially oriented polypropylene film is used as the base film, hereinafter referred to as the BOPP base film;

[0027] 2) Coating the surface of the BOPP base film to form an elastic color layer: first mix 30% polyurethane resin, 68% methyl ethyl ketone, and 1.2% accelerator and stir evenly, then add 0.8% dye and continue stirring evenly to prepare Elastic color layer material, and then apply the above elastic color layer material to the surface of the BOPP base film with a 60-mesh screen roller, and react and dry in a four-stage oven to form an elastic color layer. 80m / min;

[0028] 3) Slitting and winding the elastic film with a slitting machine to obtain the high elastic heat transfer film.

[0029] The color layer after hot stamping of the invention can be stretched along with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com