Method of forming electrode pattern for solar cell, electrode manufactured using the same and solar cell

A technology for solar cells and electrode patterns, applied in the field of solar cells, can solve the problems of continuous printability deterioration of fine serial resistance patterns, and achieve high resolution, improve printing characteristics, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

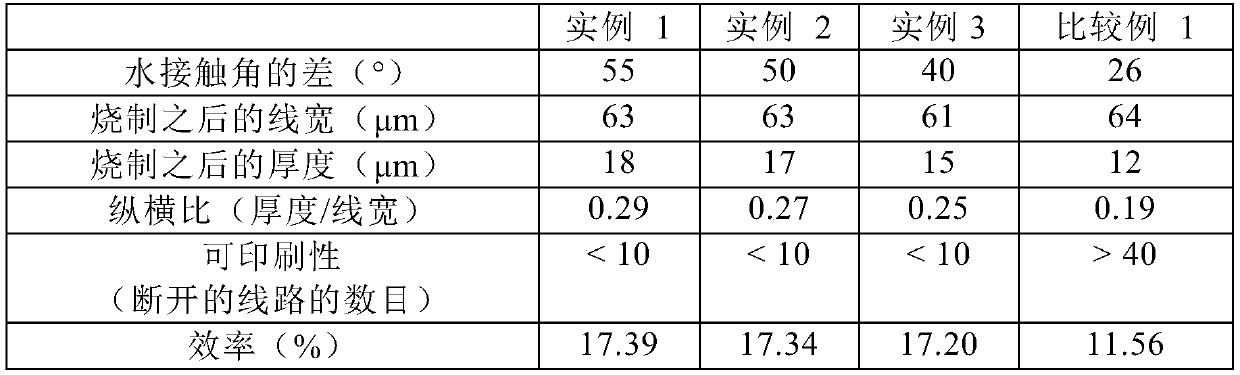

[0065] A composition for forming a solar cell electrode was prepared by adding 0.5% by weight of an organic binder (weight average molecular weight = 50,000 g / mol, STD4, Dow Chemical Company) at 60° C. Sufficiently dissolve in 7.5% by weight of butyl carbitol (Dow Chemical Co.) as a solvent, add 88.5% by weight of spherical silver powder (AG-5-11F, Tonghe High-tech Co., Ltd.) with an average particle diameter of 2.0 micrometers Co., Ltd. (Dowa Hightech Co. Ltd.)), 3% by weight of bismuth-tellurium-based lead-free glass powder with an average particle diameter of 1.0 μm (ABT-1, Asahi Glass Co., Ltd. )), 0.2% by weight of dispersant (BYK-102, BYK-Chemie (BYK-Chemie)), and 0.3% by weight of thixotropic agent (Thixatrol (Thixatrol) ST, Elementis (Elementis) Co.)), and disperse it with a three-roll machine. The composition for forming a solar cell electrode was coated on a polyethylene terephthalate (PET) film, and after distilled water was dropped thereon, a contact angle measuri...

example 2

[0067] Except using 7.5% by weight of butyl carbitol acetate (Dow Chemical Company) instead of butyl carbitol (Dow Chemical Company) as solvent, prepared according to the same method as Example 1. A composition for forming a solar cell electrode, wherein the water contact angle is 20 degrees when measured according to the same method as in Example 1.

example 3

[0069] Except using 7.5% by weight of butyl carbitol acetate (Dow Chemical Co.) Powder (AG-4-8F, Tonghe High-Tech Co., Ltd.) replaces the spherical silver powder (AG-5-11F, Tonghe High-Tech Co., Ltd.) with an average particle diameter of 2.0 microns, prepared according to the same method as Example 1 A composition for forming a solar cell electrode according to Example 3, wherein the water contact angle was 30 degrees when measured according to the same method as Example 1 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com