Paste composition for solar cell electrode

A technology for solar cells and compositions, applied in conductive materials dispersed in non-conductive inorganic materials, circuits, photovoltaic power generation, etc., can solve problems such as plate pollution, and achieve improved fluidity, excellent printing characteristics and good workability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

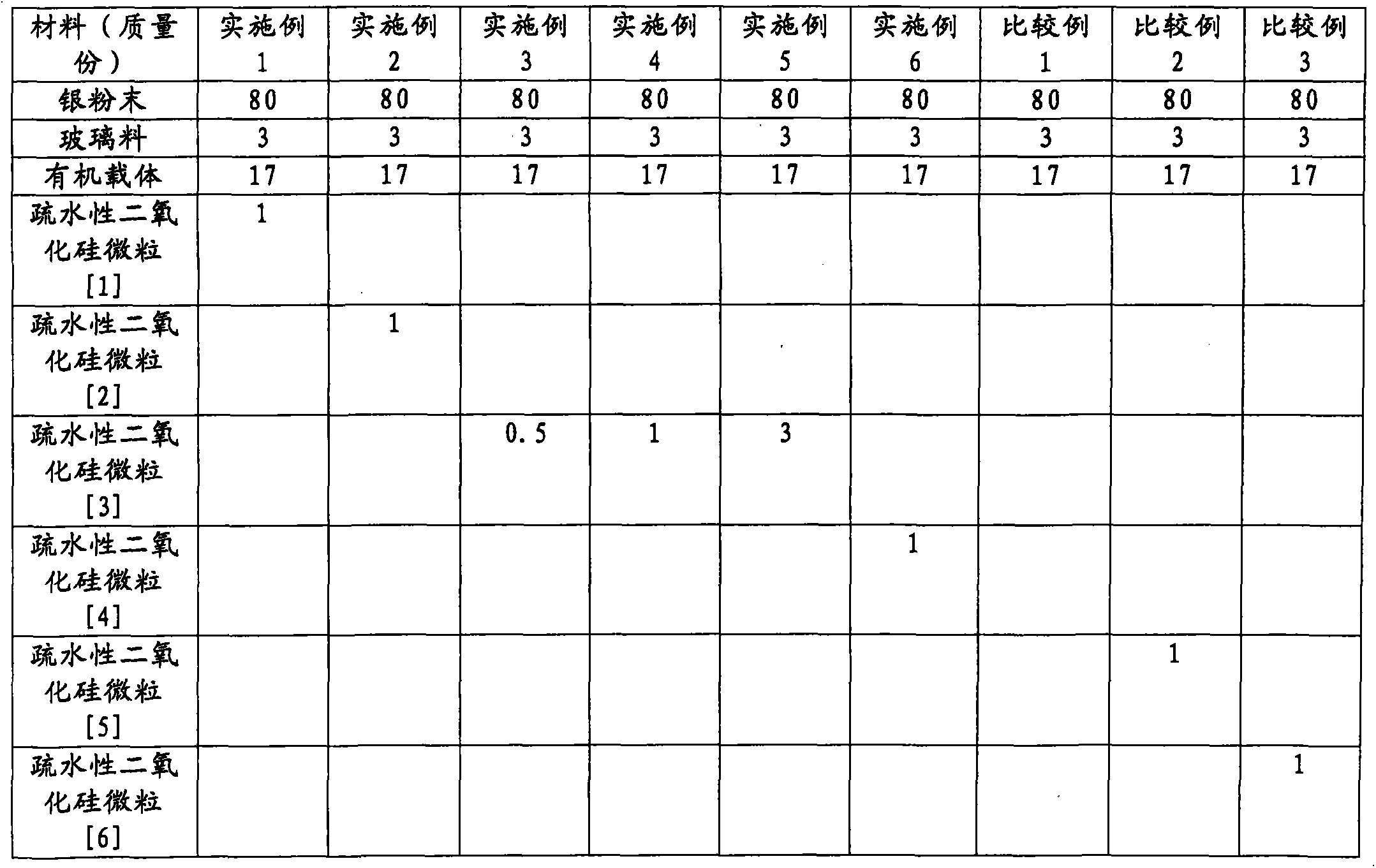

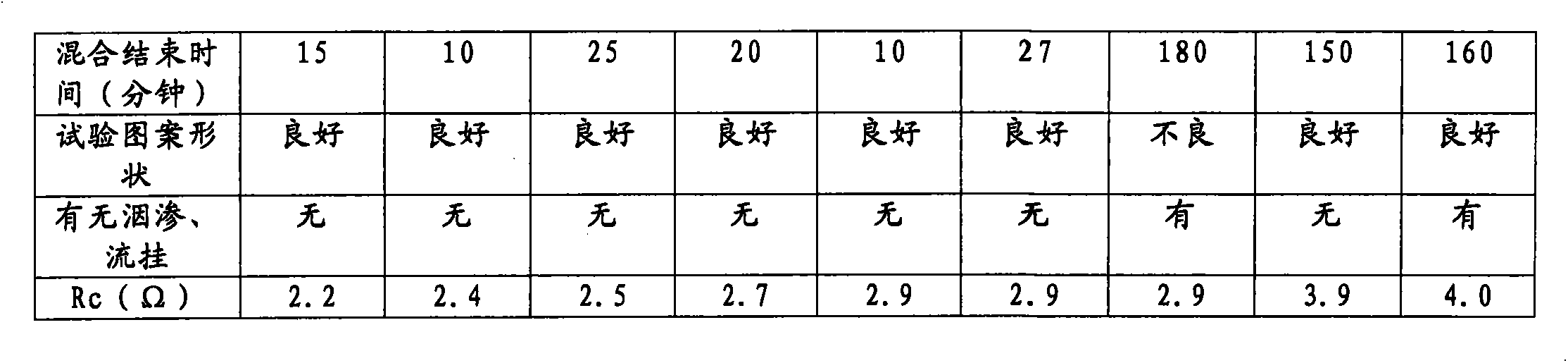

[0113] The present invention will be specifically described below using Examples and Comparative Examples. In addition, the following examples do not limit the present invention in any way.

Synthetic example 1

[0115] [Synthesis of Hydrophobic Spherical Silica Microparticles]

[0116] ・Step (A1): Synthesis of hydrophilic spherical silica particles

[0117] 989.5 g of methanol, 135.5 g of water, and 66.5 g of 28% by mass ammonia water were placed in a 3-liter glass reactor equipped with a stirrer, a dropping funnel, and a thermometer, and mixed. It adjusted so that this solution might become 35 degreeC, and it dripped 436.5 g (2.87 mol) of tetramethoxysilanes over 6 hours, stirring. After completion of the dropping, stirring was continued for another 0.5 hour to conduct hydrolysis to obtain a suspension of hydrophilic spherical silica fine particles.

[0118] ・Step (A2): Surface treatment step using a trifunctional silane compound

[0119] In the suspension obtained above, 4.4 g (0.03 moles) of methyltrimethoxysilane was added dropwise at room temperature for 0.5 hours, and the stirring was continued for 12 hours after dropping to carry out hydrophobic treatment on the surface of th...

Embodiment 1

[0136] In Example 1, in step (A1), the amounts of methanol, water, and 28% by mass ammonia water were changed to 1,045.7 g of methanol, 112.6 g of water, and 33.2 g of 28% by mass ammonia water, and hydrophobic spherical silica was obtained in the same manner. Microparticles [2] 188g. Using the hydrophobic spherical silica fine particles, it was measured in the same manner as in Synthesis Example 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com