Rewritable thermal label of non-contact type

A non-contact, heat-sensitive technology, applied in the direction of copying/marking method, identification device, temperature recording method, etc., can solve the problems of poor adhesion, inability to print, etc., and achieve the effect of excellent rewriting durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

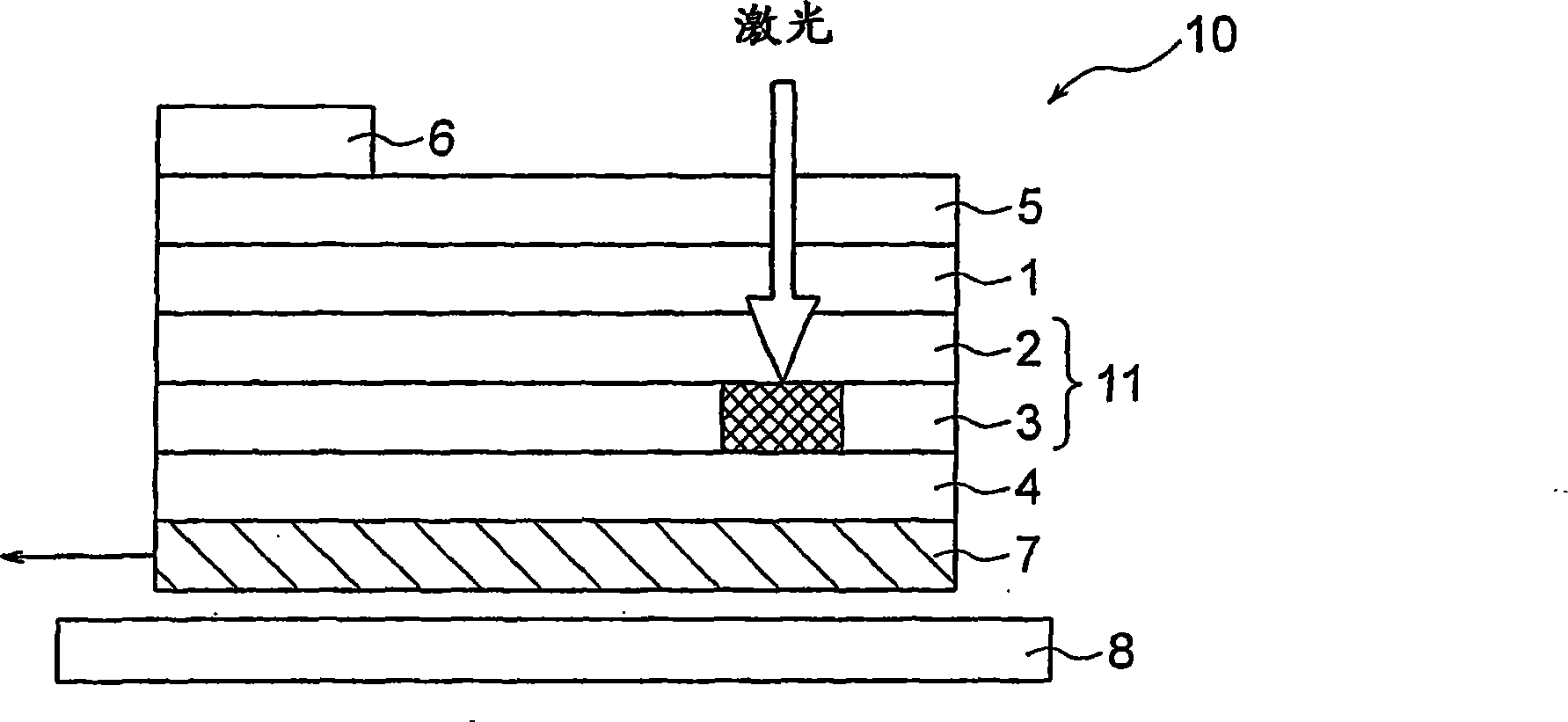

Method used

Image

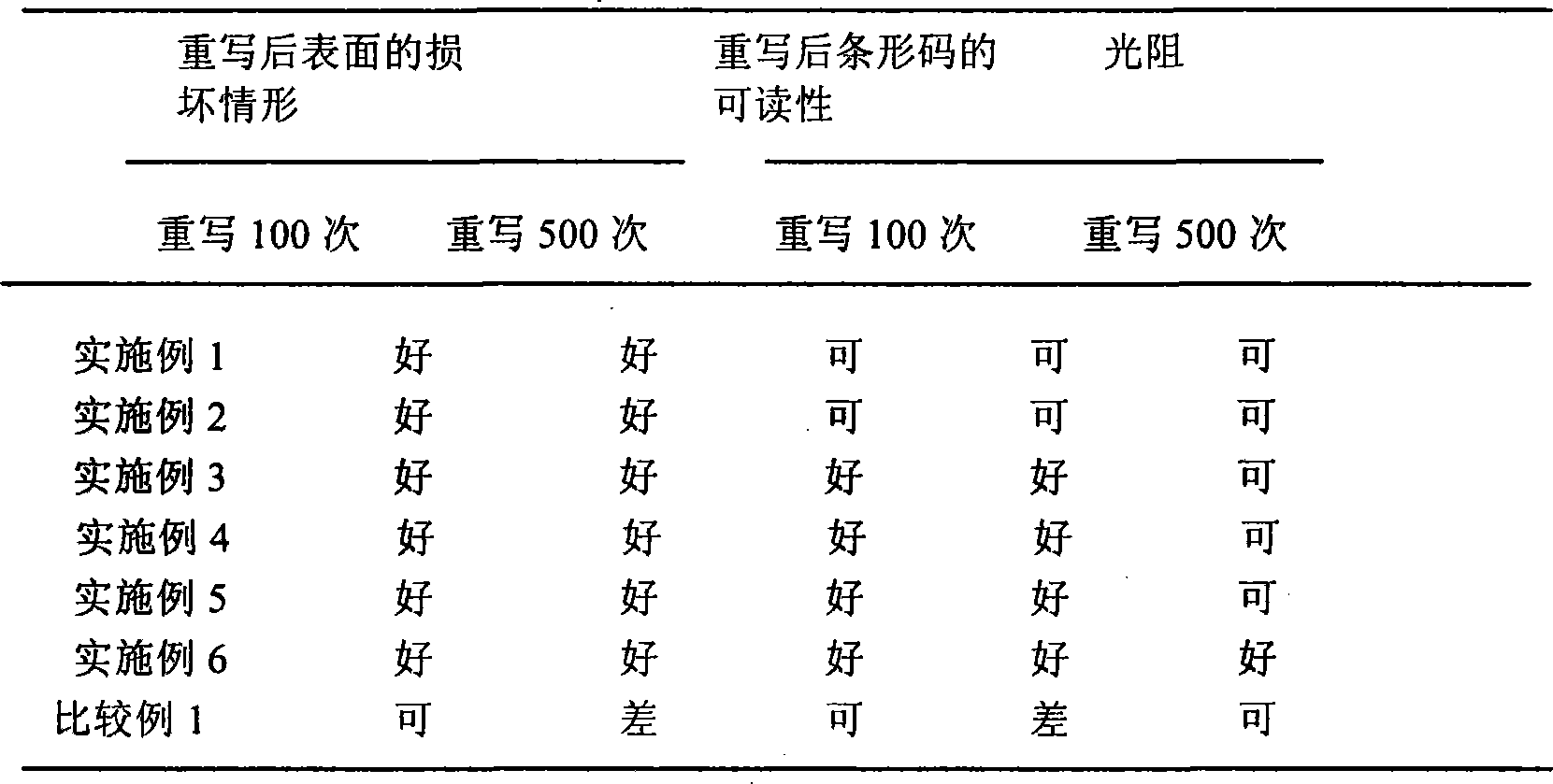

Examples

preparation example 1

[0125] Preparation Example 1 Preparation of a Coating Solution (Liquid A) for Forming a Thermosensitive Color-developing Layer

[0126] 10 parts by mass of 3-(4-diethylamino-2-ethoxyphenyl)-3-(1-ethyl-2-methylindol-3-yl)-4-nitrogen Heterophthalide, which is a triarylmethane compound, 30 parts by mass of 4-(N-methyl-N-octadecylsulfonylamino)phenol as a reversible developer, 1.5 parts by mass of a dispersant Polyvinyl acetal and 2500 parts by mass of tetrahydrofuran as a diluting solvent are ground into powder with a crusher and a disperser (disper) and dispersed to make a coating liquid (liquid A) for forming a heat-sensitive color display layer .

preparation example 2

[0127] Preparation Example 2 Preparation of Coating Liquid (Liquid B) for Forming Light Absorption and Heat Conversion Layer

[0128] 1 part by mass of a near-infrared light absorbing and converting agent (nickel complex colorant) [manufactured by TOSCO Co., Ltd., trade name: "SDA-5131"], 100 parts by mass of an ultraviolet-curable adhesive (urethane acrylate ) [manufactured by DAINICHI SEIKA Color & Chemicals Mfg Co., Ltd., trade name: "PU-5(NS)"] and 3 parts by mass of an inorganic pigment (silica) [manufactured by NIPPON AEROSIL Co., Ltd., trade name: "AEROSIL R-972" ] dispersed by a disperser to prepare a coating liquid (liquid B) for forming a light-absorbing and heat-converting layer.

preparation example 3

[0129] Preparation Example 3 Preparation of Adhesive Layer with Release Sheet

[0130] A polyethylene terephthalate (PET) film [manufactured by TORAY INDUSTRIES, INC "Lumirror T-60"] with a thickness of 100 μm was used containing a catalyst [manufactured by Dow Corning Toray Co., Ltd., trade name: "SRX-211" ] Silicone resin coating to form a coating layer with a thickness of 0.7 μm after drying to make a release sheet. The silicone resin layer on the prepared release sheet was prepared by adding 3 parts by mass of a crosslinking agent to 100 parts by mass of an acrylic pressure-sensitive adhesive [manufactured by TOYO INK MFG Co., Ltd., trade name: "ORIBAINBPS-1109"]. [manufactured by NIPPON POLYURETHANE INDUSTRY CO., LTD., trade name: "CORONATE L"] prepared pressure-sensitive adhesive coating liquid, coated according to the method using a roller coater to form a coating layer having a thickness of 30 μm after drying . The film obtained by applying the pressure-sensitive adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com