Cationic styrene-acrylate surface sizing agent and preparation method thereof

A technology of styrene acrylate and surface sizing agent, which is applied in the direction of water repellent addition, etc., and can solve the problems of affecting the sizing effect, decreasing water resistance, and making little contribution

Inactive Publication Date: 2010-10-27

SHAANXI UNIV OF SCI & TECH

View PDF2 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Oxidized starch can improve the ring compressive strength and stiffness of corrugated base paper, but it is easy to absorb moisture after film formation, which affects water resistance and ring compressive strength

The AKD surface sizing agent has good water resistance, but its affinity with fibers is poor, and its contribution to ring pressure and stiffness is not large. The emulsion is easily hydrolyzed during storage and affects the sizing effect, and there are The problem in the curing period is that it takes a certain period of time after the paper is off the machine to reach the maximum sizing degree. During the curing period, due to the absorption of water, the ring compressive strength decreases greatly, and at the same time, the water resistance also decreases. Ordinary styrene-acrylic emulsion It is prepared by emulsion polymerization of styrene and acrylate monomers. Small molecule emulsifiers are often used in the preparation process, which not only affects the water resistance of corrugated base paper but also causes environmental pollution. Currently, most styrene acrylate surface sizing agents are used. It is an aqueous solution-based anionic polymer. During use, the water contains Al3+, Ca2+, etc., which will cause emulsion precipitation and have an adverse effect on sizing.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

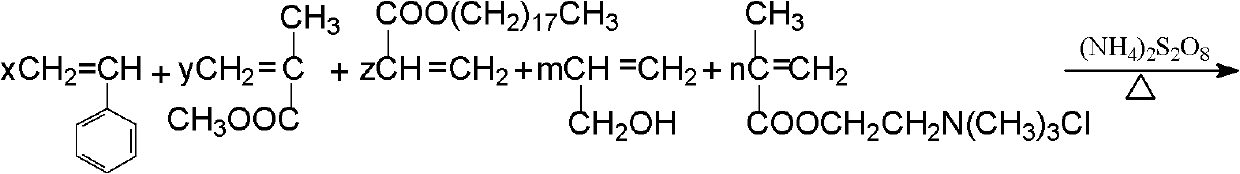

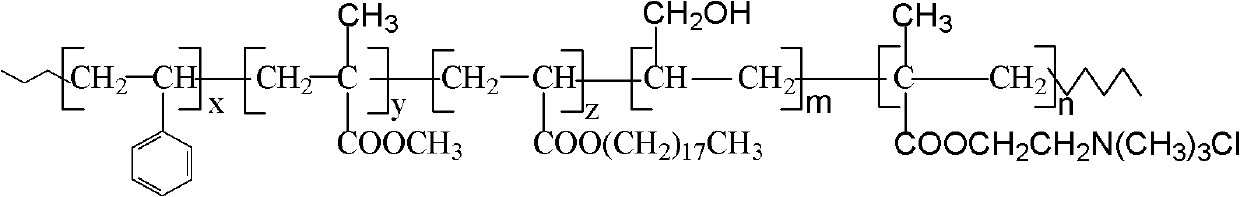

The invention discloses a cationic styrene-acrylate surface sizing agent and a preparation method thereof. The cationic styrene-acrylate surface sizing agent has a molecular structure shown in the specifications. The cationic styrene-acrylate surface sizing agent is prepared by performing soap-free emulsion polymerization reaction on polyvinyl alcohol 1788 serving as a dispersing agent, ammonium persulfate serving as an initiator, and styrene, methyl methacrylate, octadecyl acrylate, allyl alcohol and methacrylatoethyl trimethyl ammonium chloride serving as a mixed monomer. The prepared cationic styrene-acrylate surface sizing agent can form a strong ionic bond with electronegative paper fiber so as to improve the adhesion of the cationic styrene-acrylate surface sizing agent and corrugated base paper fiber and improve the ring crush strength of corrugated base paper; and simultaneously, the sizing agent forms a film layer on the surface of the corrugated base paper so as to improve the water resistance of the corrugated base paper.

Description

technical field The invention relates to the field of preparation of corrugated base paper surface sizing agents, in particular to a cationic styrene acrylate surface sizing agent and a preparation method thereof. Background technique With the rapid growth of my country's commodity export volume, the quality requirements for commodity packaging paper continue to increase, which puts forward higher requirements for my country's corrugated base paper manufacturers. Fresh fruits, food, vegetables, flowers and other agricultural products that are widely packaged and transported in corrugated cartons need to be sold by sea. It takes a long time for export commodities to be transported by sea. Due to the high humidity of the sea air, it is easy to cause the packaging cartons to absorb moisture and deform. In severe cases, the packaged commodities will be damaged and cause economic losses. At the same time, container technology is used in modern transportation, which requires frei...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D21H21/16

Inventor 张国运杨秀芳徐永建付旭东彭莉杨军胜

Owner SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com