Cationic rosin size sizing agent and preparation method thereof

A technology of cationic rosin glue and cationic rosin, which is applied in the direction of water-repellent addition, etc., can solve the problems of restricting the use of paper, poor stability of sizing agent, and low ring compressive strength of paper, and achieve the goal of improving ring compressive strength and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A method for preparing a cationic rosin size sizing agent, the preparation method comprising the following steps: (1) heating the temperature of the stainless steel reactor to 45°C, and adding 6 kg of cationic rosin size and 12 kg of vinyl acetate to the reactor after the temperature is constant , polyacrylonitrile is 2kg, tetradecyl methacrylate is 5kg, carry out sufficient mechanical stirring, stir until mixing evenly; (2) add polyoxyethylene sorbitan tristearate to stainless steel reaction kettle again and be 12kg 1. Deionized water is 240kg. Use a mechanical stirring paddle to fully stir and emulsify until the mixed solution becomes an emulsion. After becoming an emulsion, continue to stir for 30 minutes; (3) Add 4kg of alum to the stainless steel reaction kettle, and stir to fully react. The stirring time 2h; (4) After the reaction is over, cool the prepared sizing agent slowly to room temperature.

Embodiment 2

[0014] A method for preparing a cationic rosin size sizing agent, the preparation method comprising the following steps: (1) heating the temperature of the stainless steel reactor to 45°C, and adding 7 kg of cationic rosin size and 10 kg of vinyl acetate to the reactor after the temperature is constant , polyacrylonitrile is 3kg, tetradecyl methacrylate is 5kg, carry out sufficient mechanical stirring, stir until mixing evenly; (2) add polyoxyethylene sorbitan tristearate to stainless steel reaction kettle again and be 13kg 1. Deionized water is 260kg. Use a mechanical stirring paddle to fully stir and emulsify until the mixed solution becomes an emulsion. After becoming an emulsion, continue to stir for 30 minutes; (3) Add 3kg of alum to the stainless steel reaction kettle, and stir to fully react. The stirring time 2h; (4) After the reaction is over, cool the prepared sizing agent slowly to room temperature.

Embodiment 3

[0016] A preparation method of a cationic rosin size sizing agent, the preparation method comprising the following steps: (1) heating the temperature of the stainless steel reaction kettle to 45°C, and adding 8kg of cationic rosin size and 9kg of vinyl acetate to the reaction kettle after the temperature is constant , polyacrylonitrile is 2kg, tetradecyl methacrylate is 6kg, carry out sufficient mechanical stirring, stir until mixed; 1. Deionized water is 250kg. Use a mechanical stirring paddle to fully stir and emulsify until the mixed solution becomes an emulsion. After becoming an emulsion, continue to stir for 30 minutes; (3) Add 4kg of alum to the stainless steel reactor, and stir to fully react. The stirring time 2h; (4) After the reaction is over, cool the prepared sizing agent slowly to room temperature.

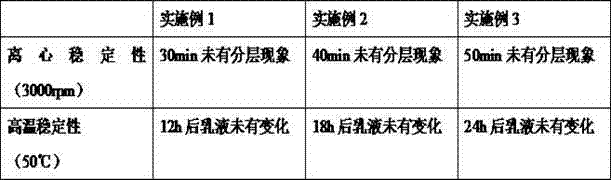

[0017] The sizing agents of Example 1, Example 2, and Example 3 were centrifuged at 3000rpm for 30min, 40min, and 50min, respectively, and then the sizing agents of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com