Preparation method for corrugated paper ring crush reinforcing agent

A technology of ring pressure strengthening and corrugated paper, which is applied in the direction of reinforcing agent addition, etc., to achieve the effect of fast curing, easy process control and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

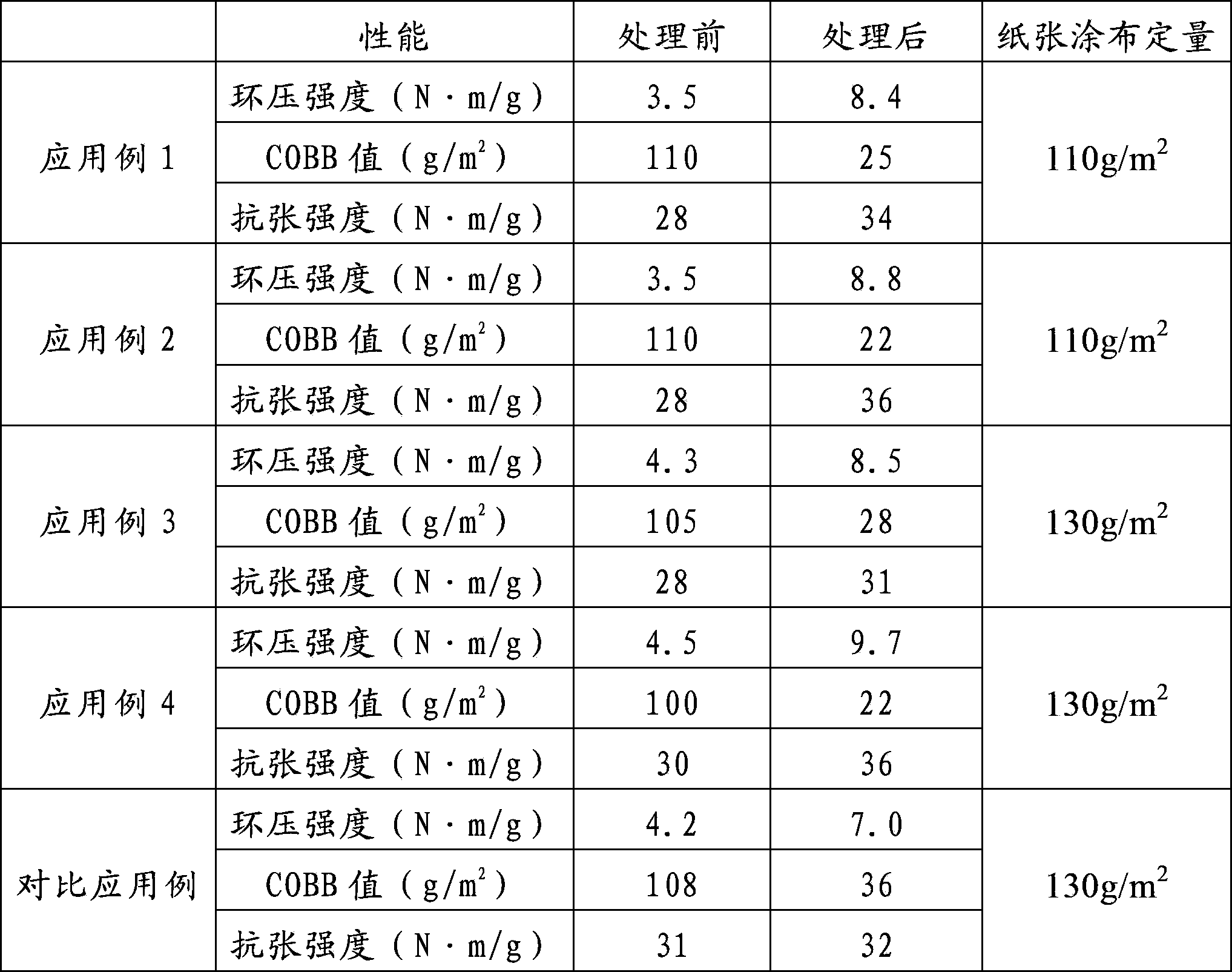

Examples

Embodiment 1

[0023] This embodiment is used to illustrate the preparation method of a kind of corrugated paper ring pressure reinforcing agent provided by the present invention, comprises the following steps:

[0024] (1) Corrugated paper ring pressure strengthening agent: Mix 50kg of glyoxal aqueous solution with a concentration of 40wt% and 1kg of p-toluenesulfonic acid evenly, adjust the pH value to 7.5-8.0, then add 15kg of melamine, heat up to 70°C, and react for 30 minutes ; then lower the temperature to 65°C, adjust the pH value to 5.5-6.0, and react for another 30 minutes; then add 10kg of methanol, continue the reaction for 30 minutes, and cool down to room temperature to obtain melamine glyoxal resin.

[0025] (2) Incomplete oxidation of starch: Add 75kg of water, 10kg of soybean starch and 0.03kg of sodium persulfate into the reactor, mix well, raise the temperature of the reactor to 85°C, reflux (to prevent excessive water loss) and keep warm for 25 Minutes, obtain the product ...

Embodiment 2

[0028] This embodiment is used to illustrate the preparation method of a kind of corrugated paper ring pressure reinforcing agent provided by the present invention, comprises the following steps:

[0029] (1) Ring pressure enhancer for corrugated paper: Mix 60kg of glyoxal aqueous solution with a concentration of 40wt% and 1.5kg of p-toluenesulfonic acid evenly, adjust the pH value to 7.5-8.0, then add 19kg of melamine, heat up to 75°C, and react for 35 minutes; then lower the temperature to 70°C, adjust the pH value to 5.5-6.0, and react for another 35 minutes; then add 21kg of methanol, continue the reaction for 40 minutes, and cool down to room temperature to obtain melamine glyoxal resin.

[0030] (2) Incomplete oxidation of starch: Add 82kg of water, 18kg of cornstarch and 0.09kg of ammonium persulfate into the reactor, mix well, raise the temperature of the reactor to 95°C, and reflux for 30 minutes to obtain incomplete cornstarch. Oxidized product 99kg.

[0031] (3) Sy...

Embodiment 3

[0033] Raw material proportioning and preparation method are the same as embodiment 1. The difference is: tapioca starch is used as the starch in step (2), 30wt% hydrogen peroxide is used as the oxidizing agent, and the amount of hydrogen peroxide used is 0.6kg when the oxidizing agent concentration is 30wt%, and the heat preservation reaction time is 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com