Preparation and application of emulsion type reinforcing agent for case board paper

An emulsion type and reinforcing agent technology, applied in the direction of reinforcing agent addition, etc., can solve the problem of insufficient ring pressure strength effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

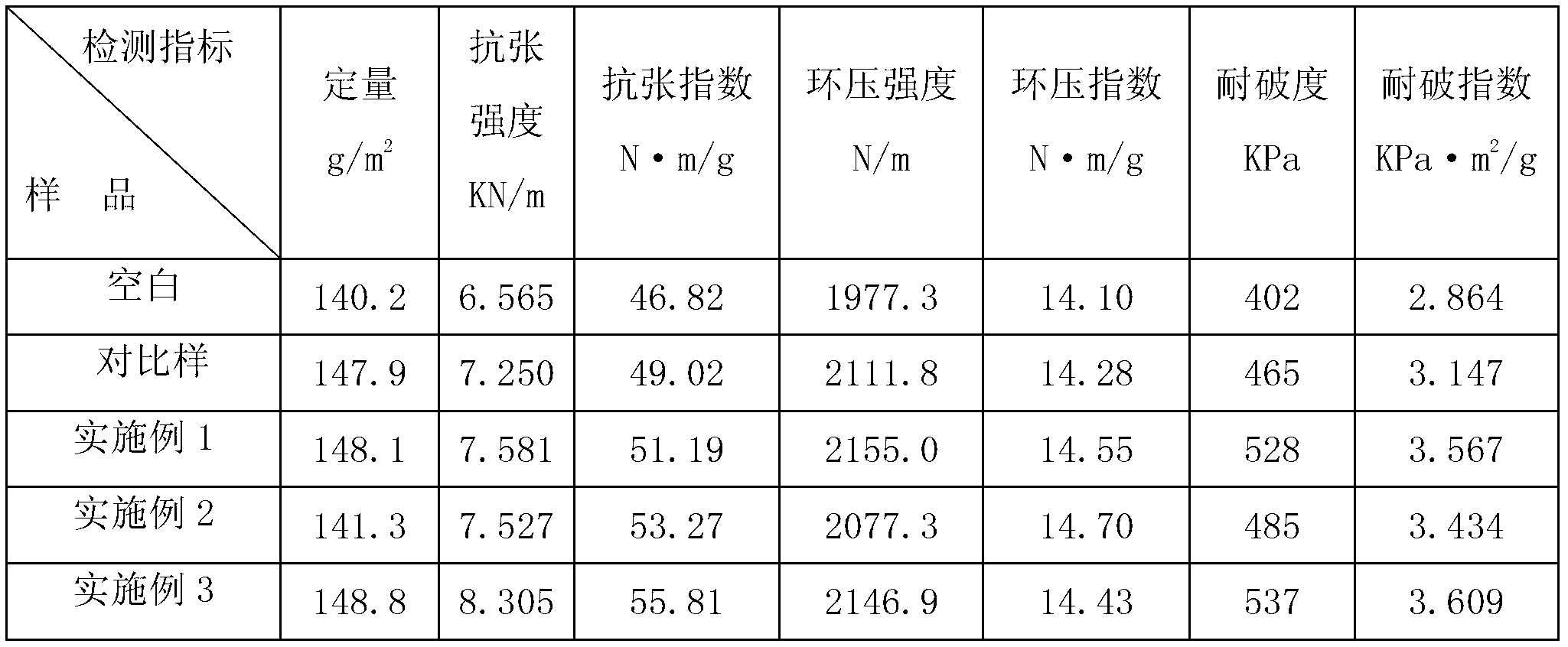

Examples

Embodiment 1

[0028] 1. Preparation of seed emulsion:

[0029] (1) Dissolve 0.2 parts of OP-10 in 10 parts of deionized water, add 30 parts of methyl methacrylate, 15 parts of butyl acrylate, and 5 parts of methacryloyloxyethyl trimethyl chloride under stirring Ammonium chloride is used to emulsify it to obtain a seed monomer pre-emulsion; 0.212 parts of ammonium persulfate is dissolved in 10 parts of deionized water to obtain a seed initiator solution;

[0030] (2) Add 350 parts of deionized water in a four-necked flask equipped with stirring, thermometer, reflux tube and constant pressure dropping funnel, start stirring, add 1.02 parts of cationic guar gum under stirring, heat up to 45°C, After 30 minutes of heat preservation, add 0.52 parts of non-ionic emulsifier OP-10 and stir evenly, raise the temperature of the water bath to 70°C, add all the seed initiator solution under stirring, then slowly add the seed monomer pre-emulsion, the dropping speed is 1.0 hours, drop After the additio...

Embodiment 2

[0036] 1. Preparation of seed emulsion:

[0037] (1) Dissolve 0.6 parts of OP-4 in 15 parts of deionized water, add 40 parts of methyl acrylate, 10 parts of ethyl acrylate, and 5 parts of dimethyl diallyl ammonium chloride under stirring to emulsify , to obtain the seed monomer pre-emulsion; 0.2 parts of sodium persulfate were dissolved in 10 parts of deionized water to obtain a seed initiator solution;

[0038] (2) Add 400 parts of deionized water into a four-necked flask equipped with stirring, a thermometer, a reflux tube and a constant pressure dropping funnel, start stirring, add 1.15 parts of cationic gelatin under stirring, heat up to 45°C, After 40 minutes of heat preservation, add 0.9 parts of non-ionic emulsifier OP-4 and stir evenly, raise the temperature of the water bath to 75°C, add all the seed initiator solution under stirring, then slowly add the seed monomer pre-emulsion, the dropping speed is 1.0 hours, drop After the addition is complete, keep warm for 35 ...

Embodiment 3

[0044] 1. Preparation of seed emulsion:

[0045] (1) Dissolve 0.5 parts of OP-10 in 15 parts of deionized water, add 36 parts of vinyl acrylate, 14 parts of isooctyl acrylate, and 2.5 parts of acryloyloxyethyltrimethylammonium chloride under stirring. It is emulsified to obtain a seed monomer pre-emulsion; 0.24 parts of potassium persulfate are dissolved in 10 parts of deionized water to obtain a seed initiator solution;

[0046] (2) Add 380 parts of deionized water in a four-necked flask equipped with stirring, thermometer, reflux tube and constant pressure dropping funnel, start stirring, add 0.9 part of cationic guar gum under stirring, heat up to 45°C, After 30 minutes of heat preservation, add 0.7 parts of non-ionic emulsifier OP-10 and stir evenly, raise the temperature of the water bath to 72°C, add all the seed initiator solution under stirring, then slowly add the seed monomer pre-emulsion, the dropping speed is 1.0 hours, drop After the addition is complete, keep wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com