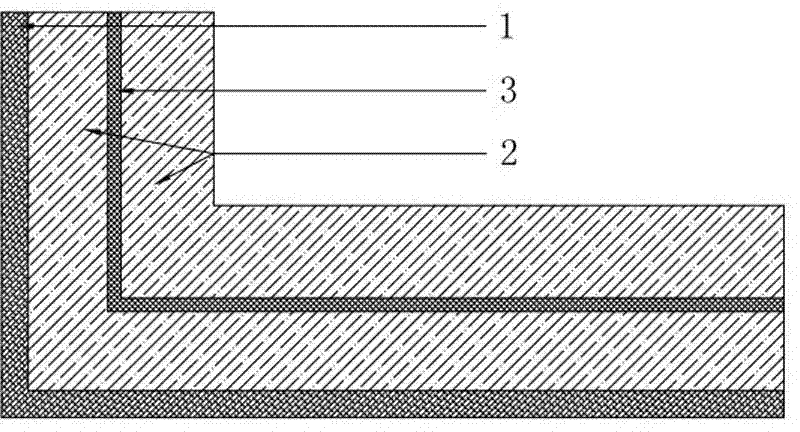

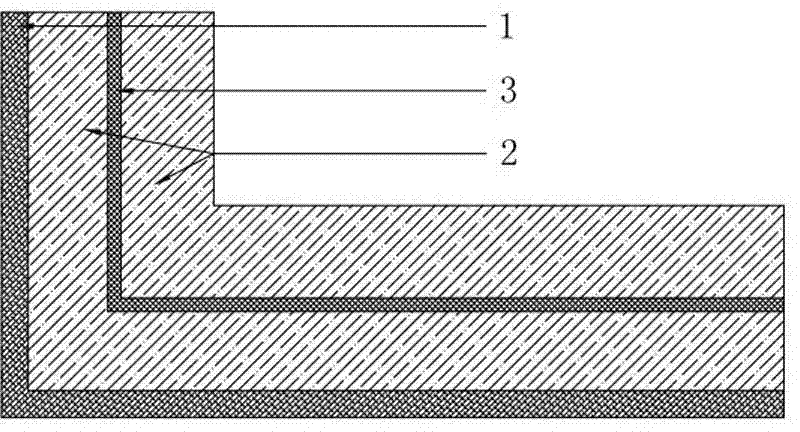

Three-dimensional fiber inorganic composite product and production method thereof

A technology of composite products and production methods, which is applied in covering/lining, construction, building construction, etc., can solve problems such as lack of reinforced concrete, large mixing amount, and fiber agglomeration, so as to reduce consumption and increase economic value , the effect of high plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) According to the weight percentage, 25kg (25%) of cement, 55 kg (55%) of sand, 3kg (3%) of glass chips, 2kg (2%) of metal chips, 0.5kg (0.5%) of carbon fiber, Alkali-resistant glass fiber 0.5kg (0.5%), PVA fiber 0.4kg (0.4%), pulp fiber 0.1kg (0.1%), toner 0.5kg (0.5%), fly ash 1kg (1%), stone powder 1kg ( 1%), 0.5kg (0.5%) of redispersible latex powder and 10.5kg (10.5%) of water are mixed evenly to make slurry for later use.

[0064] (2) Use the premixed spray method to make the decorative layer in a mold with decorative effect, and cure it naturally for 20 minutes.

[0065] (3) According to the weight percentage, 30kg (30%) of cement, 48kg (48%) of sand, 2.5kg (2.5%) of alkali-resistant glass fiber, 1.0kg (1.0%) of PVA fiber, and 0.5 kg (0.5%) of wood fiber ), polycarboxylic acid water reducing agent 0.5kg (0.5%), early strength agent triethanolamine 0.5kg (0.5%), thickener hydroxypropyl methylcellulose 0.3kg (0.3%), retarder wood calcium 0.2 kg (0.2%), metakaolin 2...

Embodiment 2

[0070] (1) According to the weight percentage, 30kg (30%) of cement, 26.5kg (26.5%) of sand, 24.8kg (24.8%) of fine stones, 2kg (2%) of mica fragments, 3kg (3%) of color paste, Aqueous naphthalenesulfonate formaldehyde condensate 0.3kg (0.3%), antifreeze calcium chloride 0.3kg (0.3%), thickener polyacrylamide 0.3kg (0.3%), coagulant wood calcium 0.1kg (0.1%) %), 2.5kg (2.5%) of redispersible latex powder and 10.2kg (10.2%) of water, stir evenly to prepare slurry for later use.

[0071] (2) Use the pre-mixed vibrating method to make the decorative layer in a mold with decorative effect, and cure it naturally for 30 minutes.

[0072] (3) According to the weight percentage ratio, 28kg (28%) of cement, 52kg (52%) of sand, 1.5kg (1.5%) of carbon fiber, 0.4kg (0.4%) of PVA fiber, 0.2kg (0.2%) of pulp fiber, PU Fiber 0.7kg (0.7%), early strength agent nitrite 0.2kg (0.2%), antifreeze potassium carbonate 0.3kg (0.3%), thickener hydroxyethyl cellulose 0.3kg (0.3%), retarder 0.2kg (0.2%), ...

Embodiment 3

[0077] (1) According to the weight percentage, mix 45 kg (45%) of cement, 21 kg (21%) of sand, 2 kg (2%) of ceramic chips, 1 kg (1%) of basalt fiber, and 1 kg (1%) of alkali-resistant glass fiber. , PU fiber 0.3kg (0.3%), PP fiber 0.7kg (0.7%), wood fiber 0.5kg (0.5%), toner 5kg (5%), early strength agent sulfate 0.4kg (0.4%), antifreeze Potassium carbonate 0.4kg (0.4%), thickening hydroxyethyl cellulose 0.5kg (0.5%), retarder 0.2kg (0.2%), metakaolin 4kg (4%), silica fume 1kg (1%) and water 17kg (17%), stir evenly to make slurry for later use.

[0078] (2) Use the premixed spray method to make the decorative layer in a mold with decorative effect, and cure it naturally for 40 minutes.

[0079] (3) According to the weight percentage, 30.8kg (30.8%) of cement, 48kg (48%) of sand, 1 kg (1%) of basalt fiber, 0.6kg (0.6%) of PP fiber, and 0.4kg (0.4%) of PU fiber , 1kg of mineral powder (1%), 1kg (1%) of fly ash, 3kg (3%) of redispersible latex powder and 14.2kg (14.2%) of water are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com