Storage tank hemispherical shell forming method for improving mechanical performance

A technology of hemisphere and storage tank, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of not taking advantage of the high strength of aluminum alloys that can be heat-treated and strengthened, and reduce design requirements, etc. It is easy to achieve wall thickness dimensions Controlling and avoiding longitudinal welds, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A method for forming a tank hemispherical shell with improved mechanical properties, comprising the steps of:

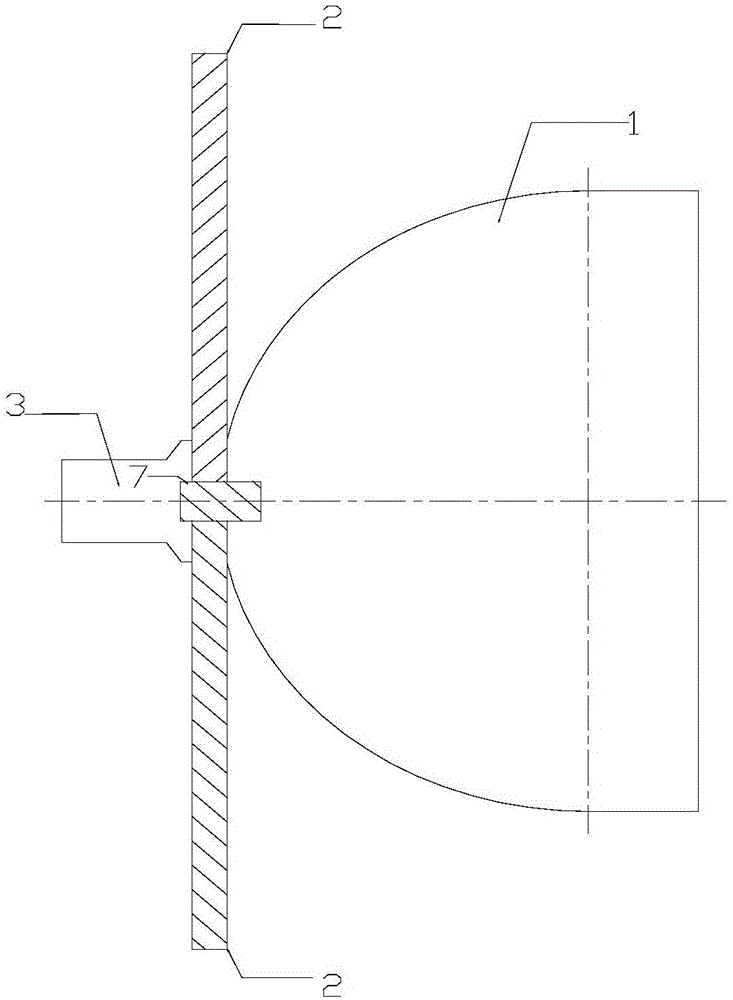

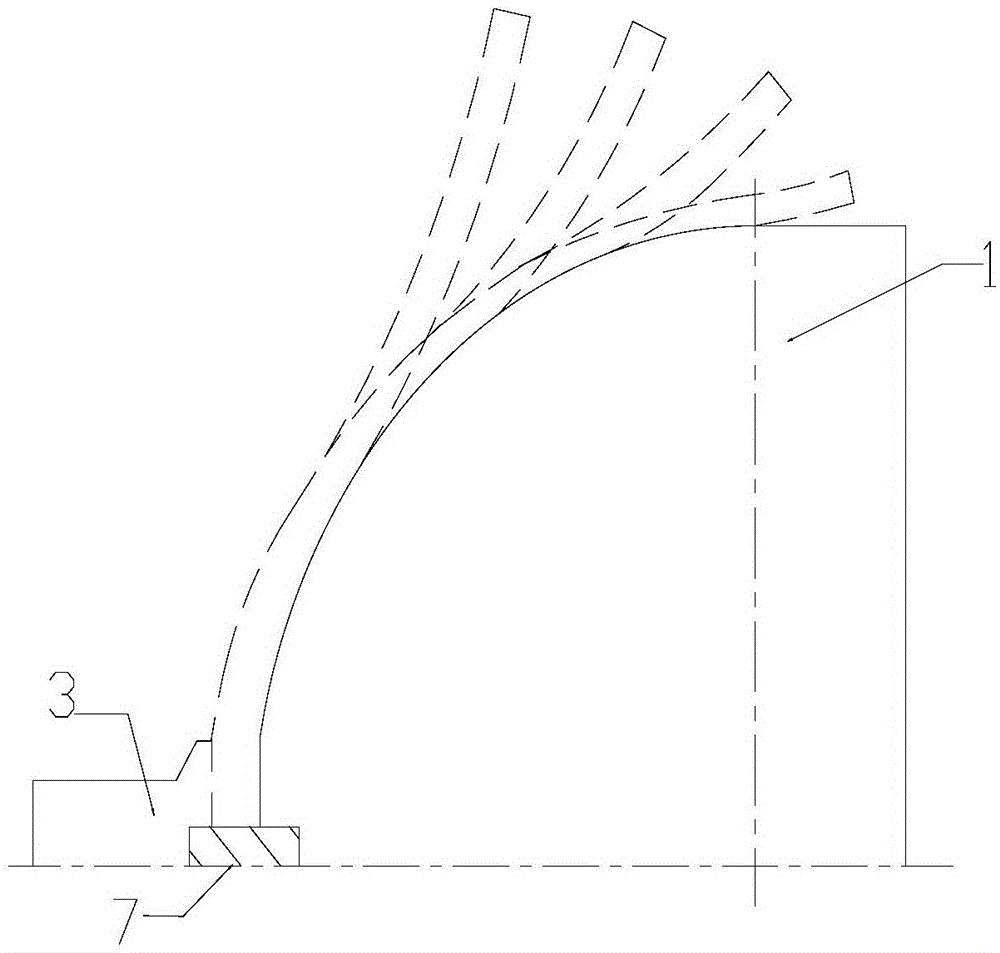

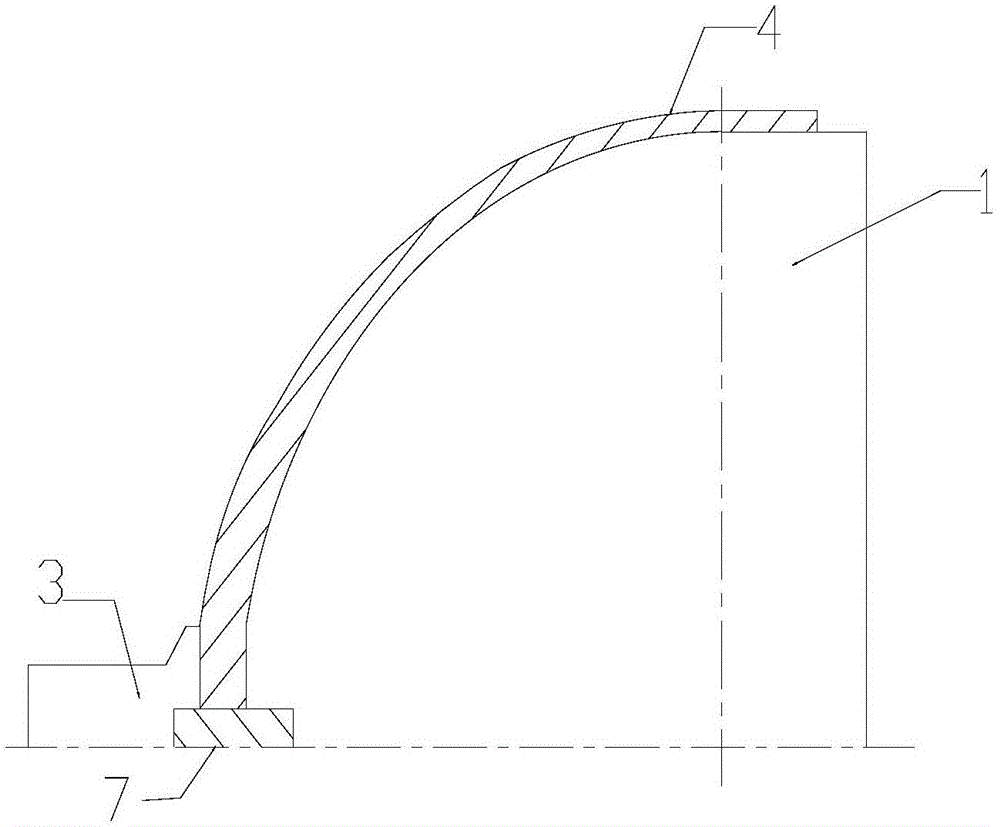

[0039] Step (1), heating the mandrel with an oxygen-acetylene spray gun, and heating the preformed spinning mandrel 1 to a temperature of 100-200°C; see figure 1, Fix the round aluminum alloy plate 2 of the blanking car on the small end plane of the spinning mandrel 1 with a steel pin, and tighten it with the tail top 3. The preformed spinning mandrel (1) is hollow inside. The preformed spinning mandrel (1) includes a hemisphere with a flat top and a cylinder coaxially connected with the hemisphere. The hemisphere with a flat top is a hemisphere with the top removed. The structure has a flat top end and a connecting end, the end face of the flat top end is parallel to the end face of the connecting end, and the radius ratio of the two end faces is: 0.3-0.5; the diameter of the hemisphere is 1-2 mm smaller than the inner diameter of the hemispherical shell of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com