Construction method for drilling depressurization hole in gob-side mining roadway

A technology for mining roadway and construction method, which is applied in drilling equipment and methods, drilling equipment, earthwork drilling, etc. and other problems, to achieve the effect of good pressure relief effect, low cost and low construction difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Take the 3201 working face of a coal mine as an example to illustrate.

[0044] The basic conditions of the 3201 working face: the mining depth of the coal mine is 1110m, the thickness of the coal seam is 3.2m, there is a strong impact tendency, and the roadway is greatly deformed by the impact of ground pressure. Therefore, it is necessary to carry out micro-disturbance strong pressure relief impact rock pressure relief hole drilling construction in the gobside mining roadway of 3201 working face.

[0045] The drilling construction of the pressure relief hole in the gob-side mining roadway shall be carried out as follows:

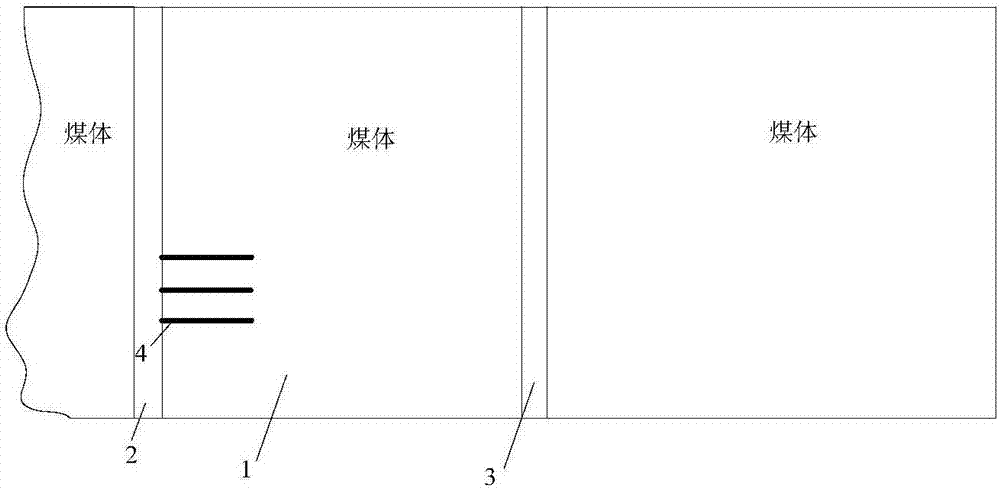

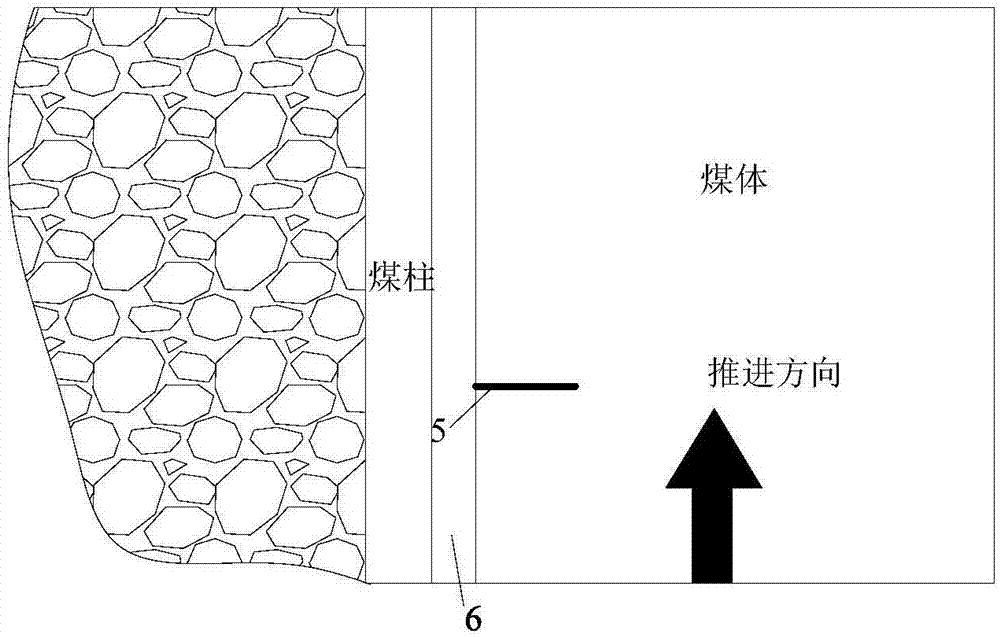

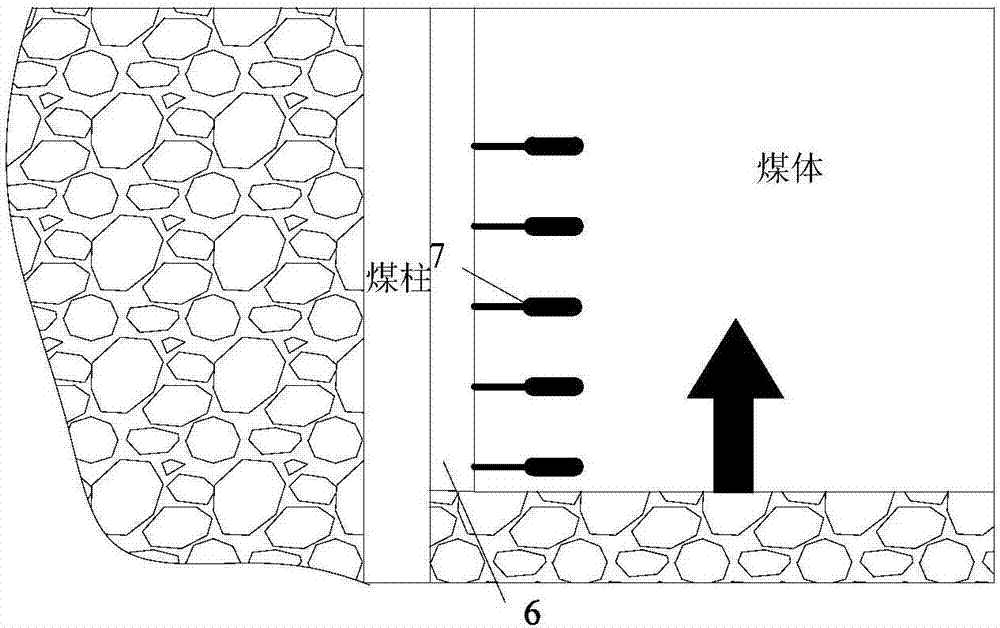

[0046] Such as Figures 1 to 3 As shown, the first step is to drill a total of 3 sampling holes A in the transport channel of the first mining face in the coal side not affected by mining, and collect and weigh the drilled coal chips;

[0047] Then, calculate the pulverized coal mass of the average per meter drilling depth of each sampling hole A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com