Reverse towing device capable of reducing longitudinal deformation of soil when box culvert is jacked in

A technology of longitudinal deformation and dragging device, which is applied in vertical shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of pipe jacking group disturbance, high construction precision requirements, complicated construction by pipe curtain method, etc. Economic cost and time cost, the effect of avoiding post-consolidation settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

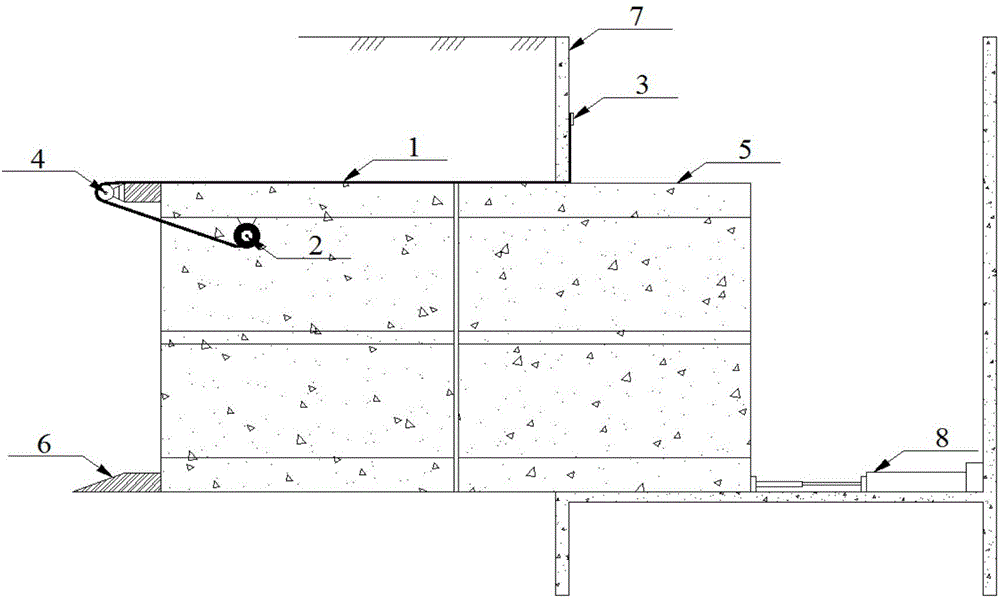

[0025] An anti-drag device that reduces the longitudinal deformation of the soil during box culvert jacking. It is usually used alone on the top of the box culvert structure, and can also be used around the box culvert structure. It is used to replace the pipe curtain method and contact method in box culvert jacking technology. Supporting technologies such as changing mud, its structure is as follows figure 1 As shown, this supporting device for the box culvert jacking method is mainly composed of a dragging plate 1, a storage component 2 inside the dragging sleeve, an anchoring component 3 outside the dragging sleeve and a drag reducing pulley 4.

[0026] The storage component 2 in the towing sleeve and the drag reducing pulley 4 reserve embedded parts when pouring the first section of the box culvert pipe joint. After the pouring is completed, the storage component 2 in the towing sleeve can be a The rotating pulley, the storage assembly 2 and the drag reduction pulley 4 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com