Large recovered oil and gas tank

A large-scale technology for oil and gas storage tanks, which is applied in the field of large-scale recycled oil and gas storage tanks. It can solve problems such as large diameter, storage tank quality defects, and processing difficulties, and achieve the effects of reducing the difficulty of pressing, easily ensuring the quality of forming, and reducing the number of welds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

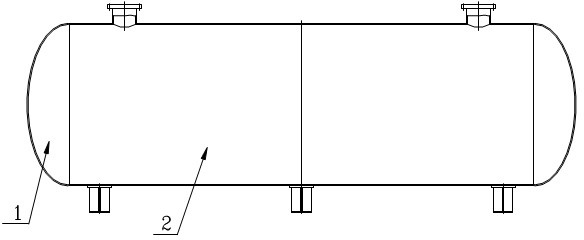

[0022] Specific embodiment 1 of the present invention, as figure 1 As shown, a large-scale recovery oil and gas storage tank is assembled and welded by a head 1 and a cylinder 2.

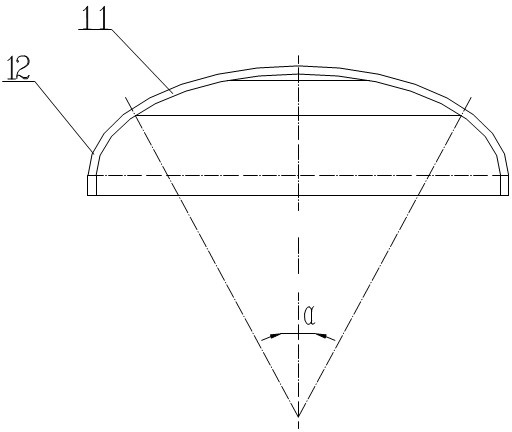

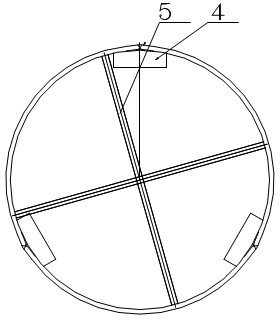

[0023] The equipment head is an oval head, such as figure 2 As shown, the diameter is DN6500mm, and the thickness is 50mm. Because the diameter is too large, the forming quality is difficult to guarantee, and the transportation is difficult after the overall forming. The press-formed petals are pair-welded, and the petals are pressed by cold pressing. First, they are pressed with a blank. After forming, the scribing is cut off and the welding groove is opened. The measured geometric dimensions of each petal after forming meet the requirements of Specifies the requirements. Among them, the petals include top circular plate 11 and side plate 12, among which, there are 3 pieces of top circular plate 11 and 10 pieces of side plate 12. Because the head is assembled and welded with the cylinder after f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com