Novel technique for producing seamless steel pipe

A technology of seamless steel pipe and new technology, which is applied in the direction of manufacturing tools, metal processing equipment, rolling mill control devices, etc., can solve the problems of expensive cold drawn pipe machine, many processing procedures, high equipment cost, etc., and achieve excellent physical and chemical properties of products, The effect of simple technology and low investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

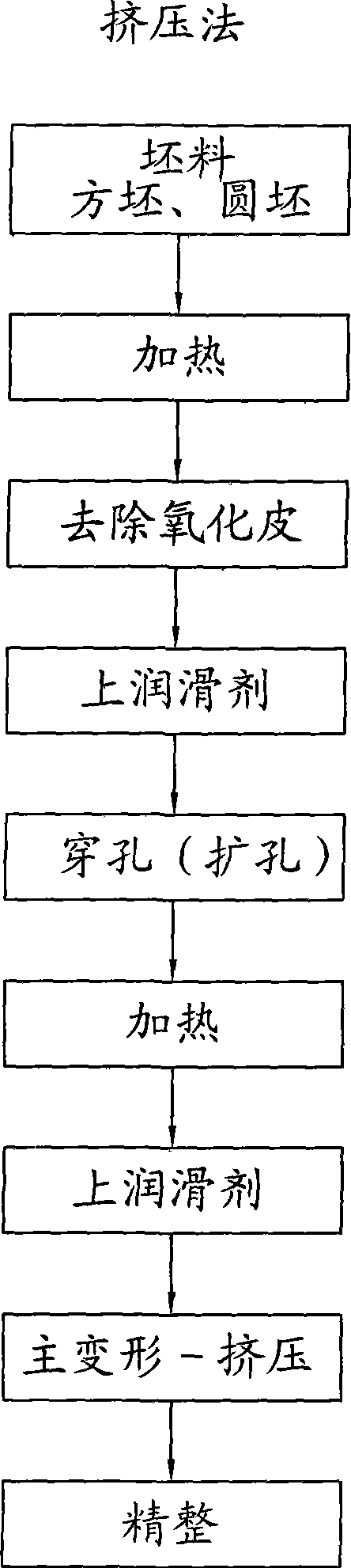

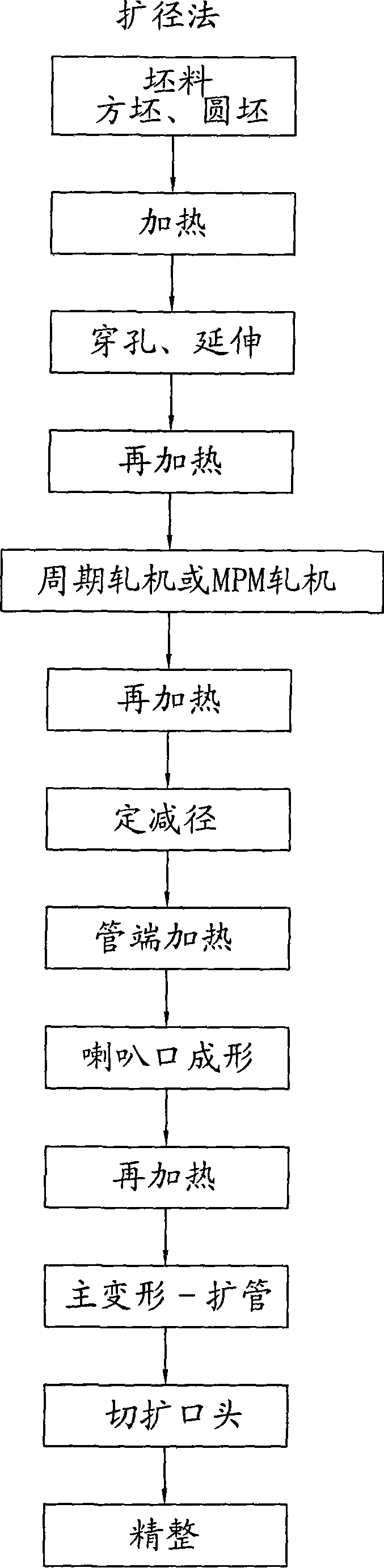

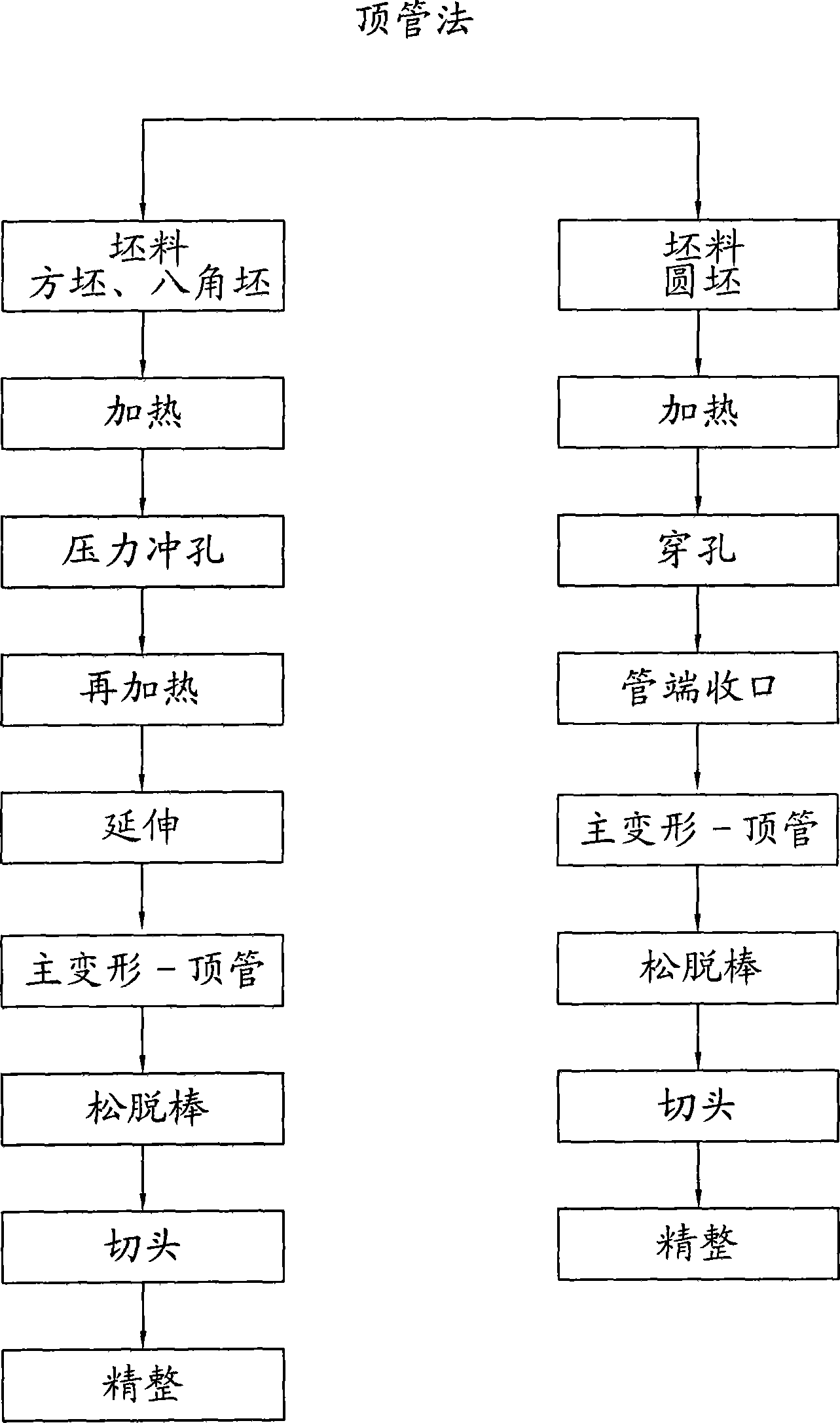

Method used

Image

Examples

Embodiment Construction

[0073] like Figure 4 As shown, according to the first embodiment provided by the present invention, the following process steps are included:

[0074] The first step is to produce a large-diameter and medium-thick-walled hollow billet by centrifugal casting; the centrifugal casting is carried out on an inclined centrifugal casting machine with an angle between the rotation axis of the mold and the horizontal, that is, the inclination angle is 15 to 30 degrees. The large-diameter thick-walled hollow billet produced by centrifugal casting is a hollow billet with an inner diameter closing at one end, that is, a hollow billet with a ring-shaped cup bottom at one end, that is, the inner diameter at the end becomes smaller, forming a hollow billet with a cup bottom 2 1. This cup bottom 2 has a hollow part 21, such as Figure 5 shown. The arrangement of the above-mentioned structure can be beneficial to the subsequent jacking process, and the end of the mandrel of the pipe jacking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com