Construction process for prestress support in deep foundation pit

A construction technology and prestressing technology, which is applied in foundation structure engineering, sheet pile walls, excavation, etc., can solve problems such as deformation, hidden safety hazards in pipelines, and unsuitable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

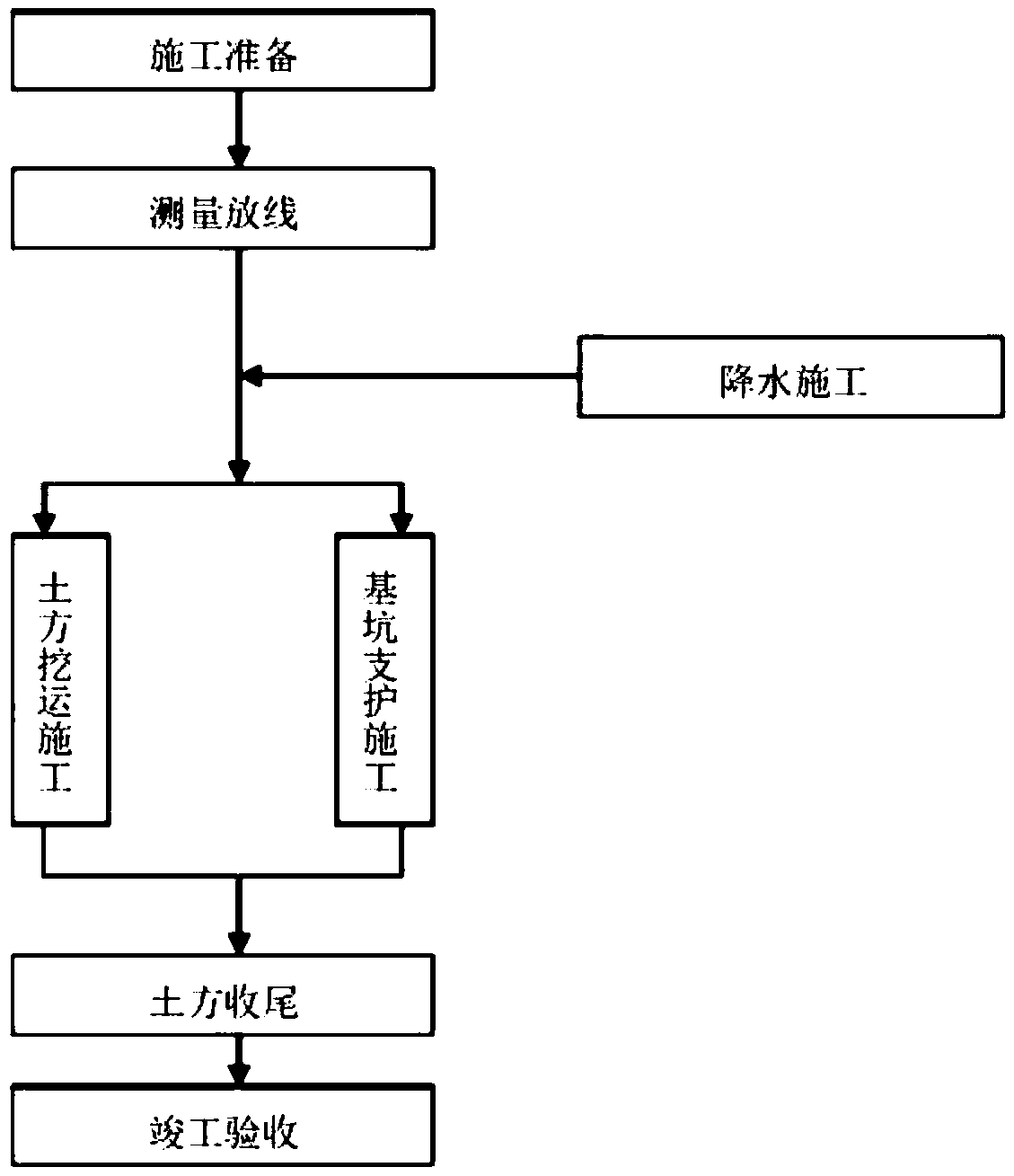

[0090] Example: such as figure 1 As shown, the construction technology of the prestressed support in the deep foundation pit specifically includes the following steps:

[0091] (1) Clean up the site and set out the construction line: clean up the site, and each pile position should be positioned and set out with theodolite and steel tape according to the design requirements;

[0092] (2) Construction preparation: Prepare the required materials and enter the site in batches, and then enter the site after overhauling and maintaining the required mechanical equipment to ensure good performance of the mechanical equipment;

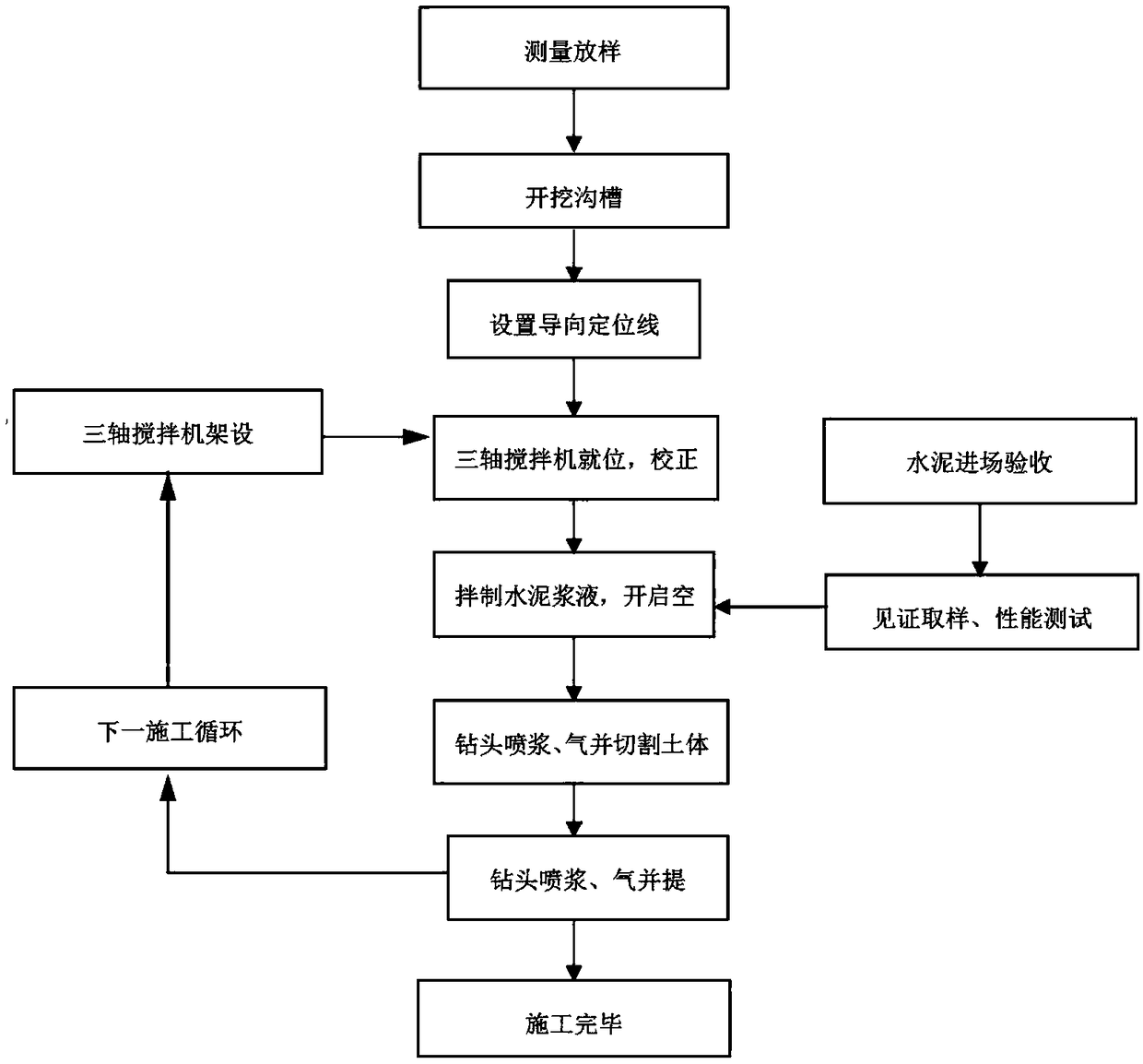

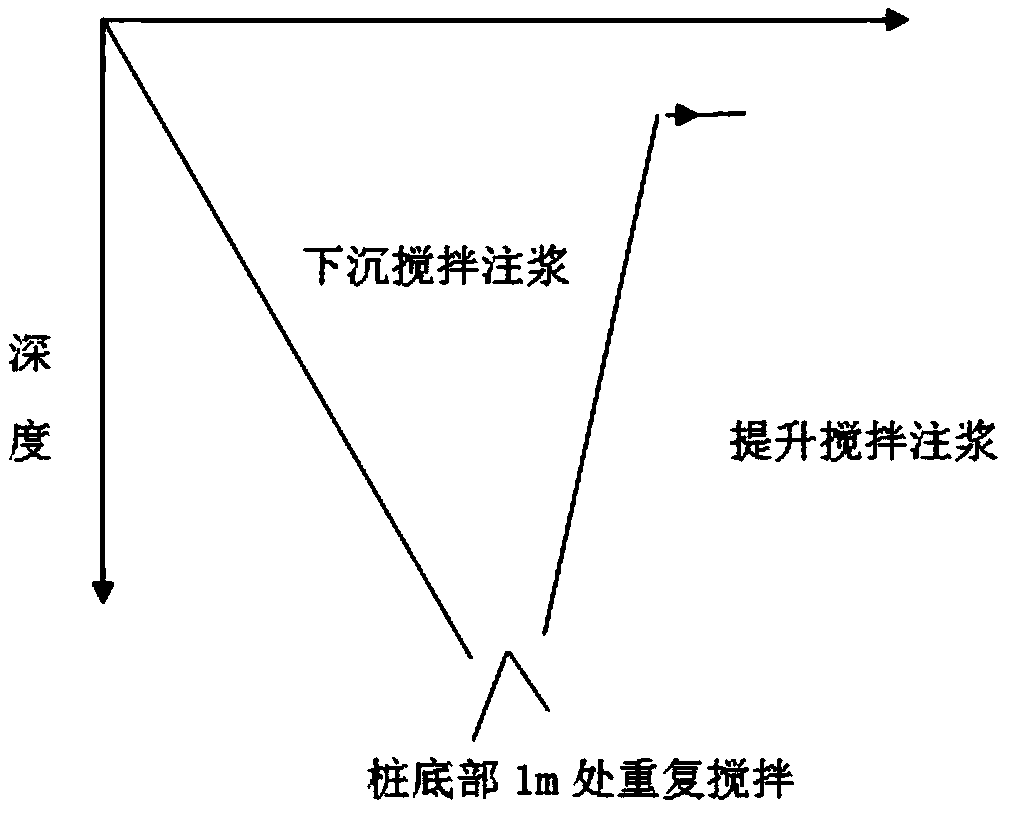

[0093] (3) Constructing the enclosure project: the enclosure method adopts three-axis mixing pile water stop, bored cast-in-situ pile, biaxial mixing pile, reinforced anchor pile and anchor shotcrete, and double-split waist beam to apply prestress; among them, the order is first Connecting and interspersing construction of three-axis mixing piles for water-st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com