Reinforced concrete inner support with pre-stressed loaders for supporting foundation pit

A reinforced concrete and foundation pit support technology, which is applied in the direction of basic structure engineering, excavation, construction, etc., can solve the problems of reinforced concrete support such as prestressing, difficult control, large deformation of foundation pit, etc., to achieve large span and large support rigidity , The effect of controllable foundation pit deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

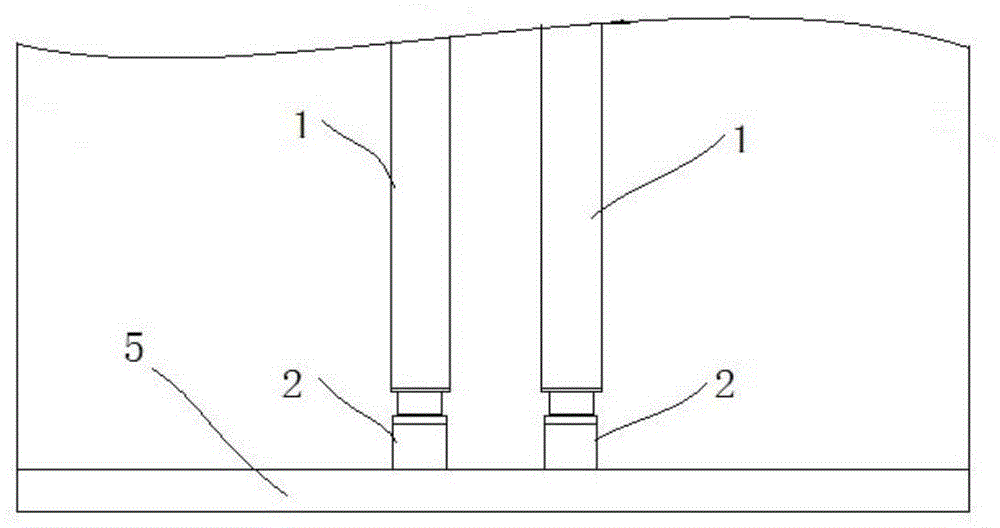

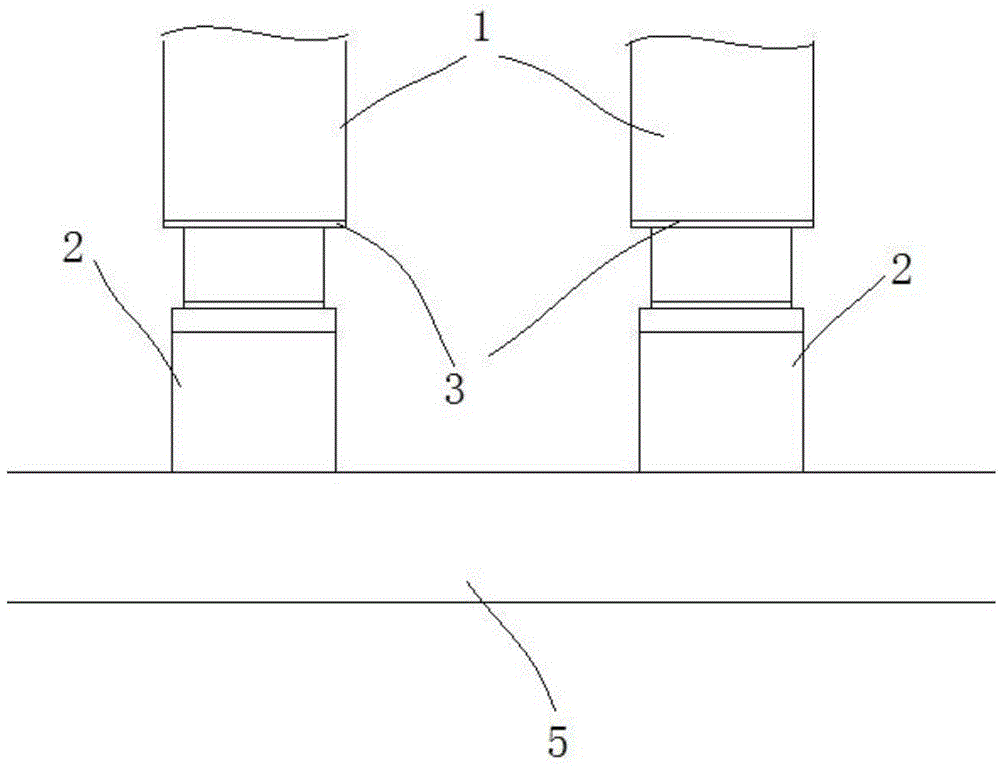

[0020] Embodiment 1, see figure 1 and figure 2 , shown in the figure is a foundation pit adopting the structure of reinforced concrete counter brace 1, and the counter brace 1 is a structure of two side by side, of course, a single or multiple counter brace 1 can also be set as required. It can be seen that when the earth pressure on the outside of the foundation pit changes, the prestress of the reinforced concrete brace 1 needs to be adjusted accordingly to offset the earth pressure on the outside of the foundation pit.

[0021] For this reason, at the connection between the end of the brace 1 and the purlin 5, a disconnected end face is provided, and a prestress loader 2 is arranged on each disconnected end face of the brace 1, and the prestress loader 2 One end is pushed against the disconnected end face of the brace 1, and the other end is pushed against the purlin 5. In order to facilitate the pressing of the loader 2, a steel plate 3 is provided on the end face of th...

Embodiment 2

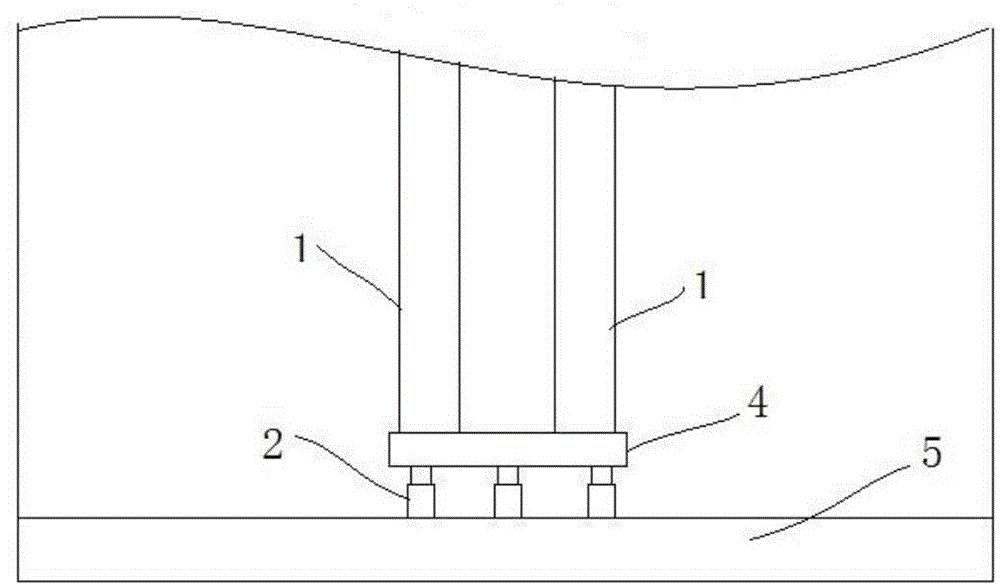

[0023] Example 2, see image 3 and Figure 4 , it can be seen that the reinforced concrete brace 1 is two side-by-side structures, and of course a single or multiple braces 1 can also be provided as required. At the connection between the end of the brace 1 and the purlin 5 , a disconnected end surface is provided for setting the prestress loader 2 . Specifically, a top plate 4 is provided at the end face of the brace 1, and a prestressed loader 2 is arranged between the top plates 4. There are a plurality of loaders 2, which are evenly distributed between the top plate 4 and the purlin 5. Purlin 5 and top plate 4 apply prestress, loader 2 directly applies prestress to one end of purlin to offset the earth pressure, and the other end transmits prestress to counter brace 1 through top plate 4 to be transferred to the purlin of the foundation pit to offset earth pressure. The purlin 5 is a steel concrete composite purlin.

[0024] The top plate 4 is a reinforced concrete str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com