Filter-press type water electrolyzer

A water electrolysis cell and filter press technology, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of increasing the voltage drop of the electrolyte, uneven pole distance, and increasing energy consumption, so as to simplify the electrolysis process and improve the Current efficiency, the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

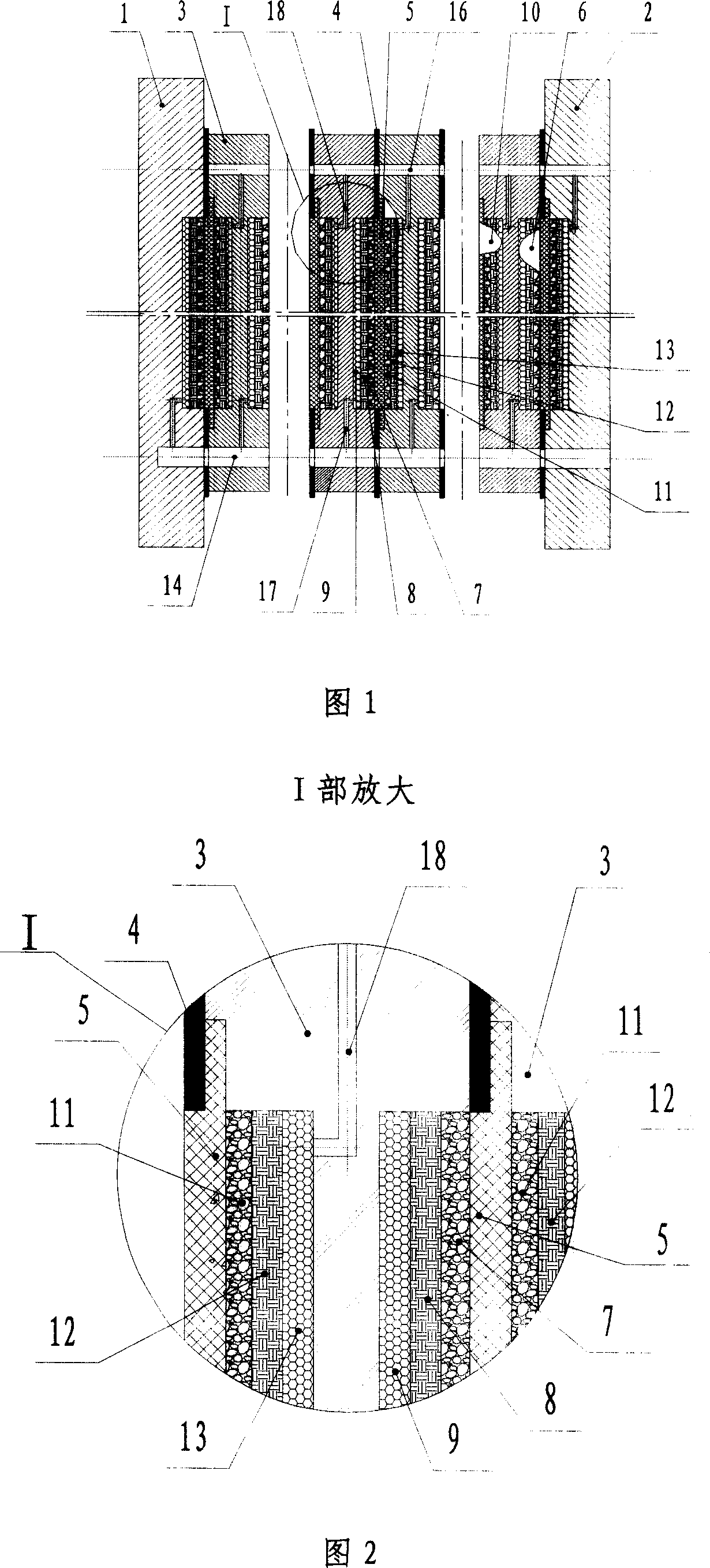

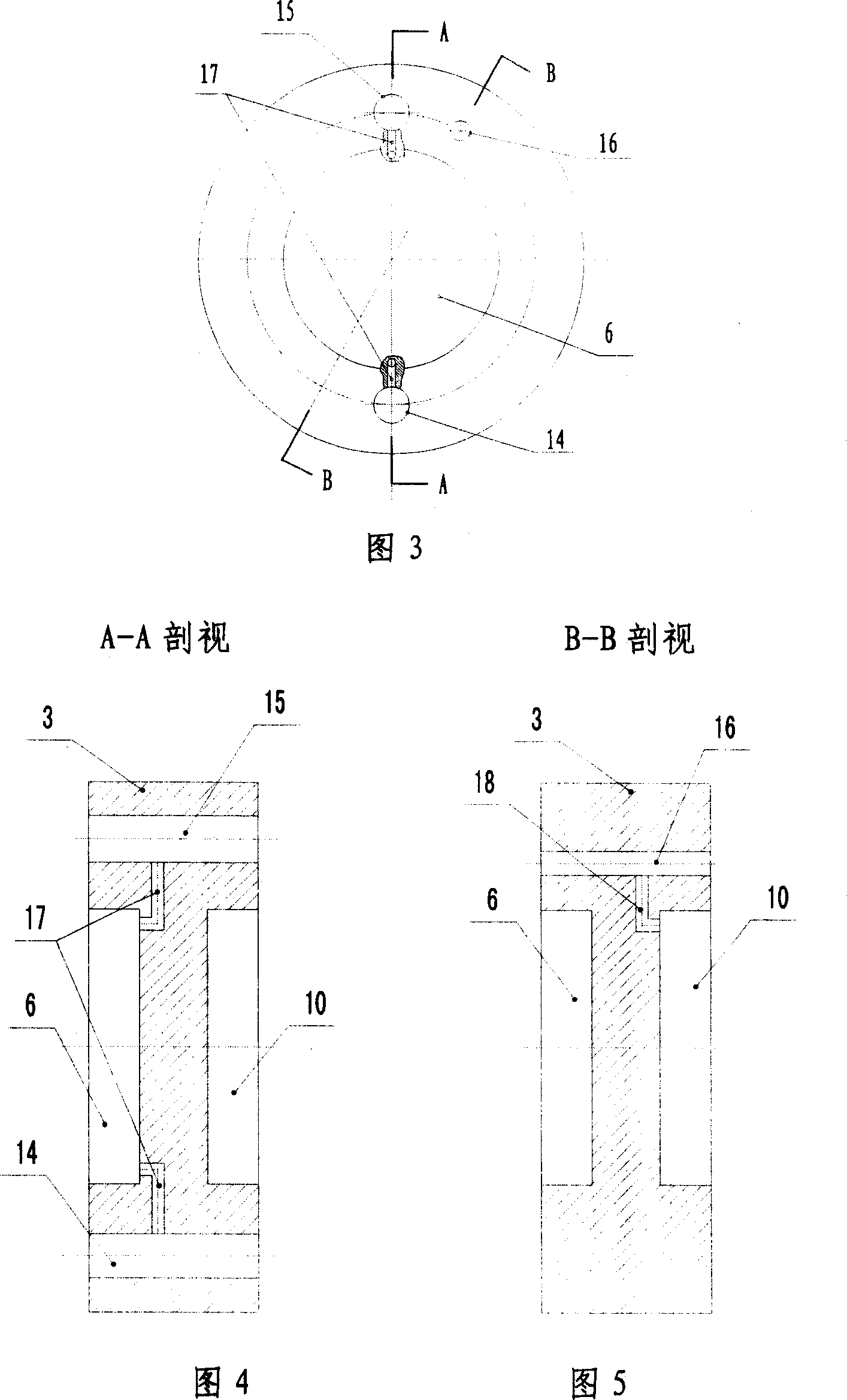

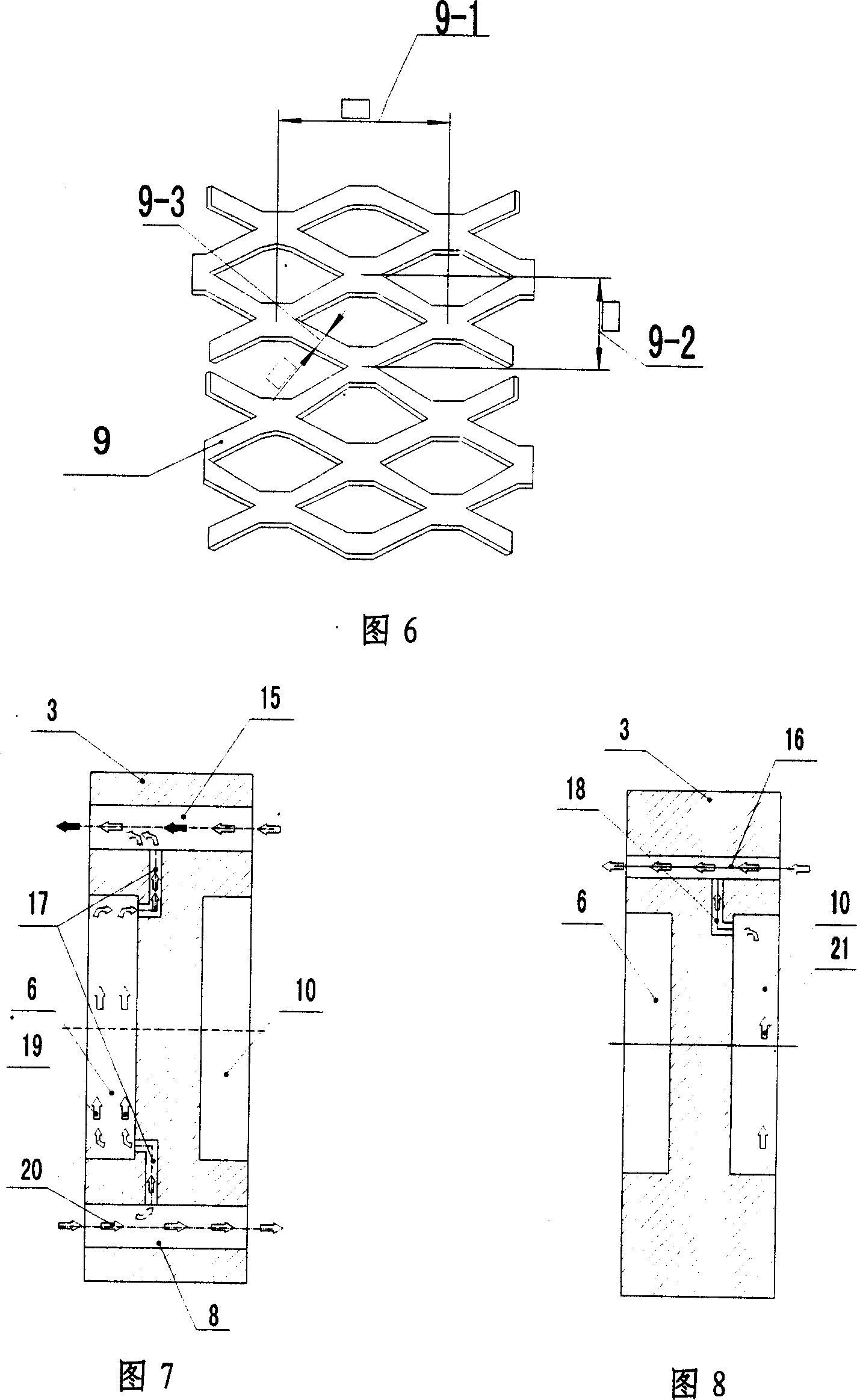

[0041] Embodiments of the present invention and their effects will be further described below in conjunction with the accompanying drawings.

[0042]With reference to accompanying drawing 1,2 pressure filter type water electrolyzer comprises anode half-cell body 1, cathode half-cell body 2, at least one bipolar unit cell body 3 positioned between the two, and the insulation between the three Sealing gasket 4, diaphragm 5, the anode chamber 6 of anode half cell body 1, bipolar unit cell body 3 is installed flexible metal or by the netted main anode 7 of metal wire weaving, meshed auxiliary anode 8 and have An anode support assembly 9 with air-permeable and liquid-permeable mesh structure and elastic expansion performance, a flexible metal or a mesh-shaped main cathode 11 woven by metal wire is installed in the cathode chamber 10 of the cathode half-cell body 2 and the bipolar unit cell body 3 , Mesh-shaped auxiliary cathode 12 and cathode support assembly 13 with air-permeable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com