Liquid crystal panel and manufacturing method thereof

A technology for a liquid crystal panel and a manufacturing method, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of increasing the size of the liquid crystal panel, the difficulty of designing a narrow frame, and the requirement of increasing the cutting accuracy, so as to improve the overflow and reduce the design difficulty. The effect of the requirement on panel cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

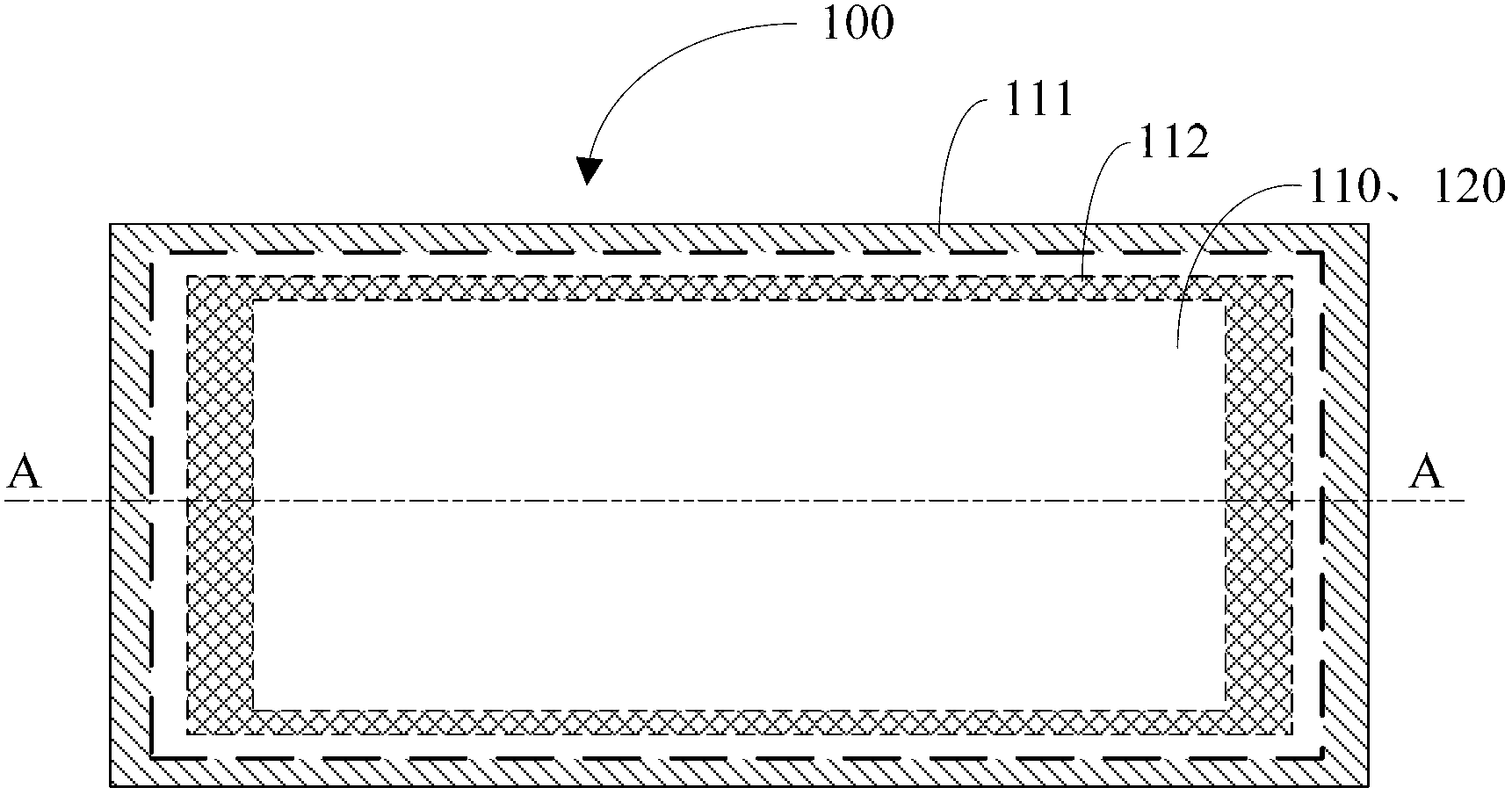

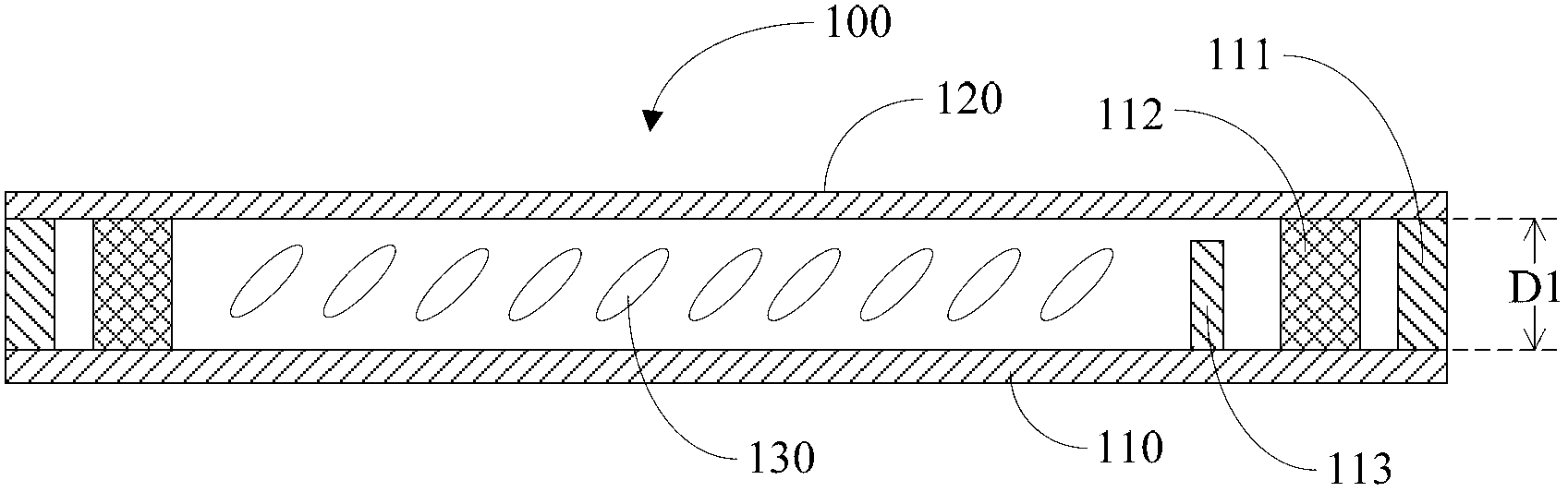

[0023] refer to figure 1 , figure 1 It is a top perspective schematic view of the liquid crystal panel according to the first embodiment of the present invention. figure 2 Yes figure 1 A schematic cross-sectional view of the liquid crystal panel in A-A.

[0024] Please also refer to figure 1 And and figure 2 As shown, in this embodiment, the liquid crystal panel 100 includes a first substrate 110 , a second substrate 120 , a retaining wall 111 , a sealant 112 and a liquid crystal 130 .

[0025] The first substrate 110 is opposite to the second substrate 120 .

[0026] In this embodiment, the first substrate 110 is a color filter substrate, and the second substrate 120 is a thin film transistor array substrate. Alternatively, the first substrate 110 is a thin film transistor array substrate, and the second substrate 120 is a color filter substrate. In other embodiments, the first substrate 110 may be an active element array substrate in other forms, and the second subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com