Floating type aerating and feeding dual-purpose machine

A suspended and dual-purpose technology, which is applied in the field of fish farming, can solve the problems of affecting the walking of breeders, unfavorable feeding and growth of fish, a large amount of manpower and time, and achieves the advantages of convenient feeding, no floor space occupation, and high utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

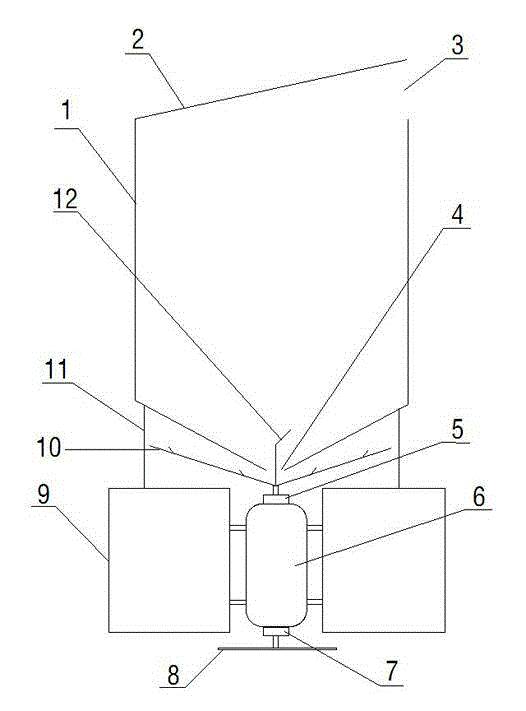

[0025] Feed box 1 and motor 6 are all fixed on the buoyancy box 9 that foam or buoyant barrel are made by fixed mount 11, and whole feeding machine is fixed on the fish pond center with rope.

[0026] The motor 6 is running, use the remote controller to combine the output shaft of the motor 6 with the remote clutch I5, the output shaft at the upper end of the motor 6 rotates, and the output shaft is connected to the feeding tray 10 through the remote clutch I5 with the remote control device to rotate, and the feeding box will be fed 1. The feed falling into the feeding tray 10 is thrown out along the parabolic path on the feeding tray 10 by centrifugal force, and the feeding process is completed; the output shaft of the motor 6 is separated from the remote control clutch I5 by the remote controller, and the feeding tray 10 stops rotating , stop feeding.

[0027] In the same way, the motor 6 is running, and the output shaft of the motor 6 is combined with the remote control clu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com