Linear sliding rail lubricating system

A lubricating system and linear slide rail technology, applied in the direction of engine lubrication, linear motion bearings, bearings, etc., can solve the problems of uneven service life, shortened service life, and inaccurate machining accuracy of the balls of the linear slide rail.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

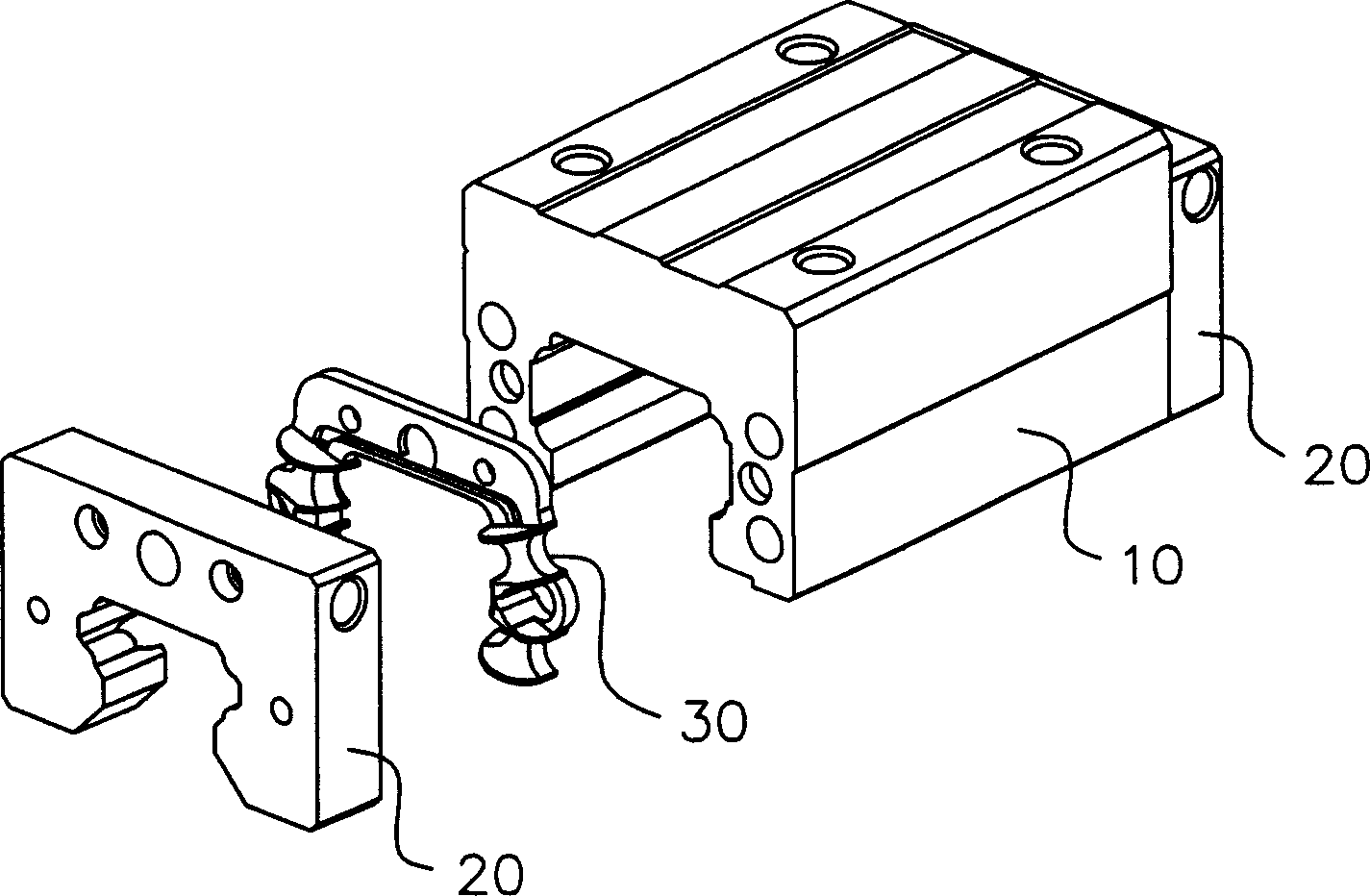

[0033] figure 1 It is a three-dimensional schematic diagram of the lubrication system of the linear slide rail of the present invention; wherein, end caps 20 and cover plates 30 are provided at both ends of the slider 10, and the end caps 20 and cover plates 30 can be combined into a complete reflux groove for the balls to turn and return.

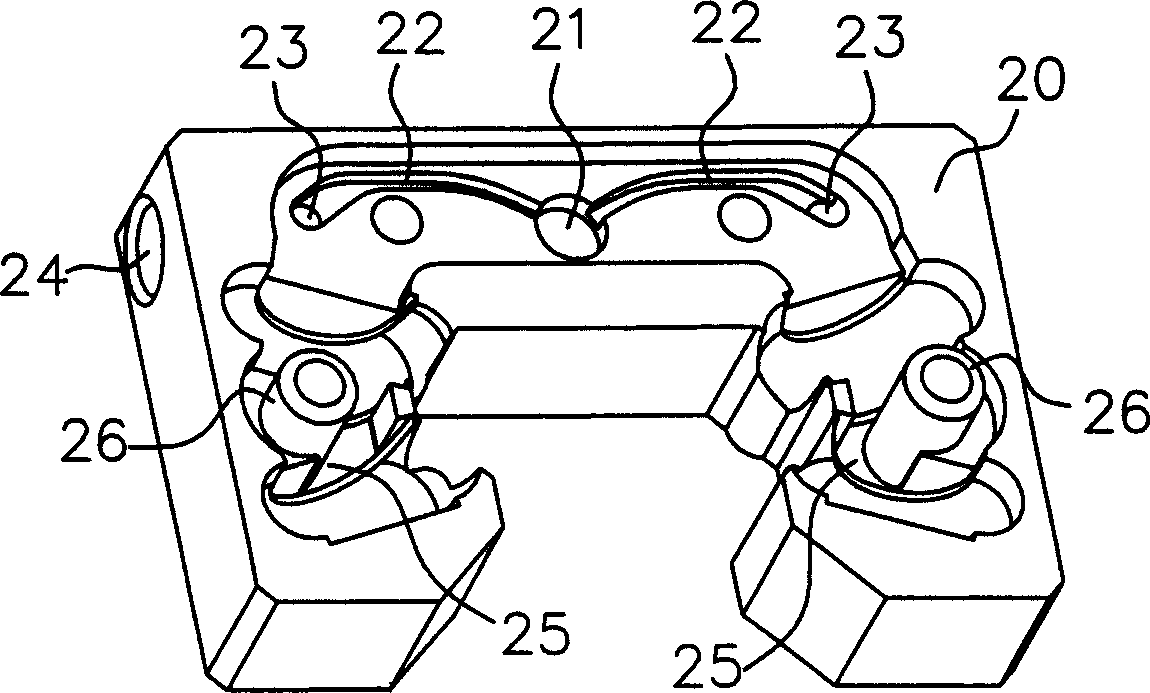

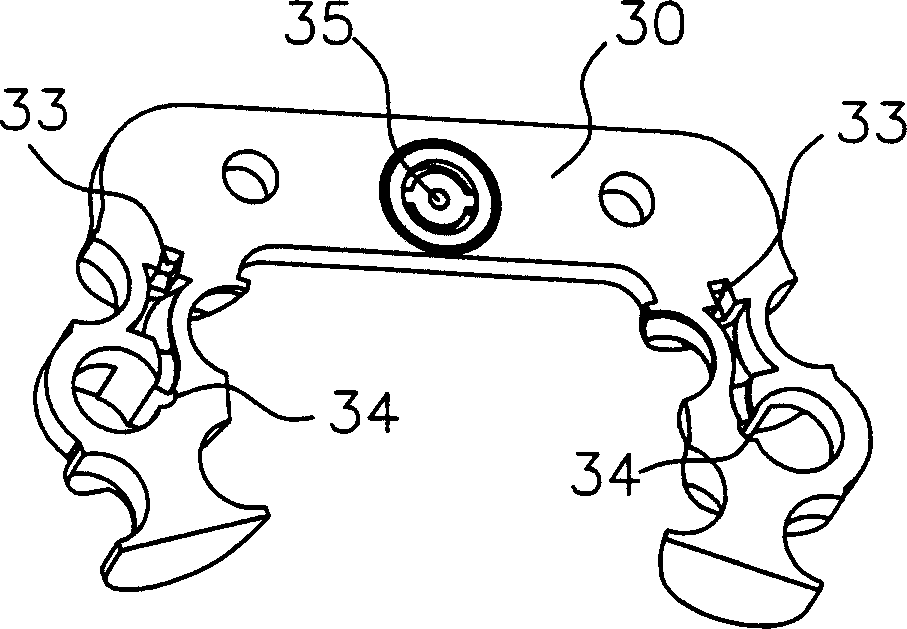

[0034] figure 2 for figure 1 The three-dimensional schematic diagram of the end cap; image 3 for figure 1 Front perspective schematic diagram of the cover plate; Figure 4 for figure 1 The perspective view of the reverse side of the cover plate; the end cover 20 has two oil injection directions: the oil injection hole 21 on the end surface and the oil injection hole 24 on the side. Part 35 has the effect of blocking the lubricating oil from flowing to the end surface of the slider. The lubricating oil is led to both sides from the guide oil passage 32, and then enters the oil holes 33 on both sides to transfer the lubricating oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com