Multi-station automatic assembly machine for quick coupler

A multi-station, assembly machine technology, applied in assembly machines, metal processing, manufacturing tools, etc., can solve the problems of low manual assembly efficiency of quick joints, missing parts, cumbersome procedures, etc., to achieve rapid assembly and reduce the rate of defective products , The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

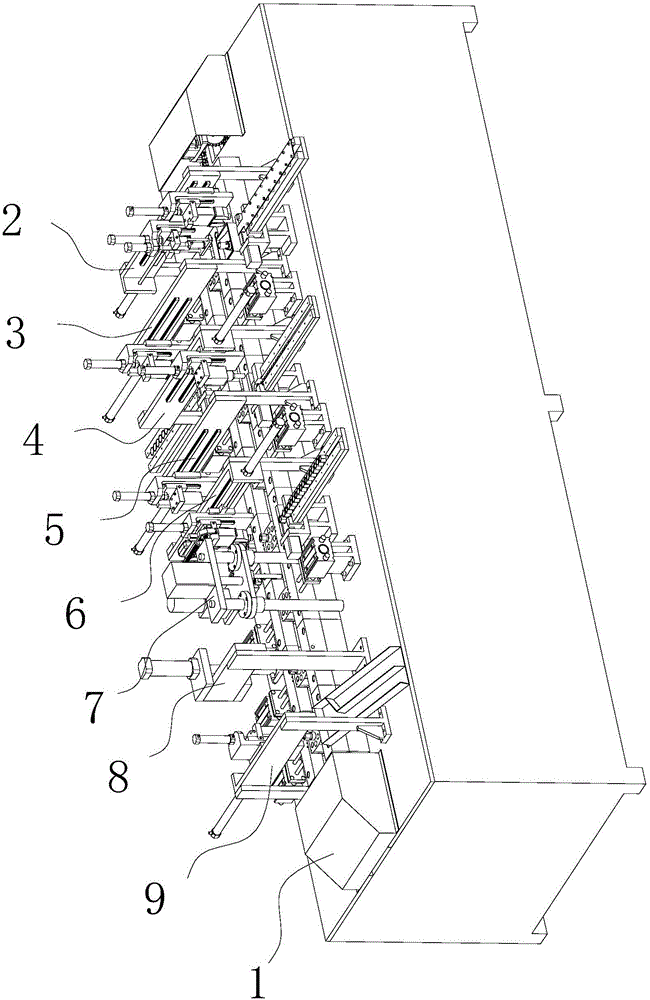

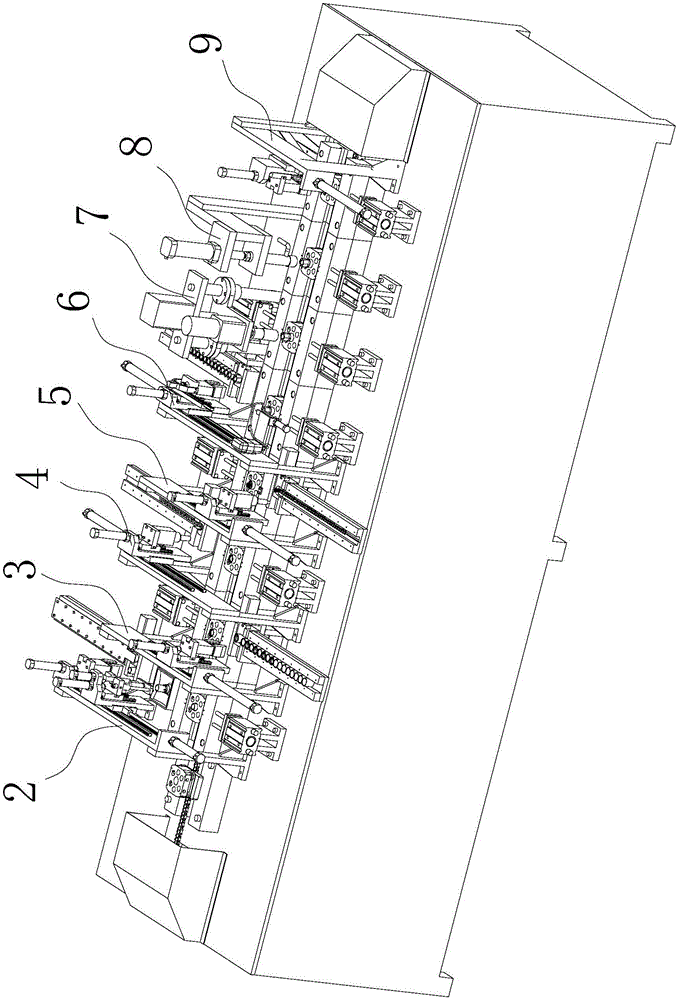

[0041] refer to figure 1 and figure 2 As shown, the main structure of the multi-station quick connector automatic assembly machine is a workpiece transmission mechanism 1 driven by a stepping motor to realize stepping motion. In the transmission direction of the workpiece transmission mechanism 1, there are: central loading station 2, Jacket feeding station 3, gasket feeding station 4, valve core feeding station 5, nut feeding and pre-tightening station 6, nut locking station 7, air tightness testing station 8 and pick-up station 9.

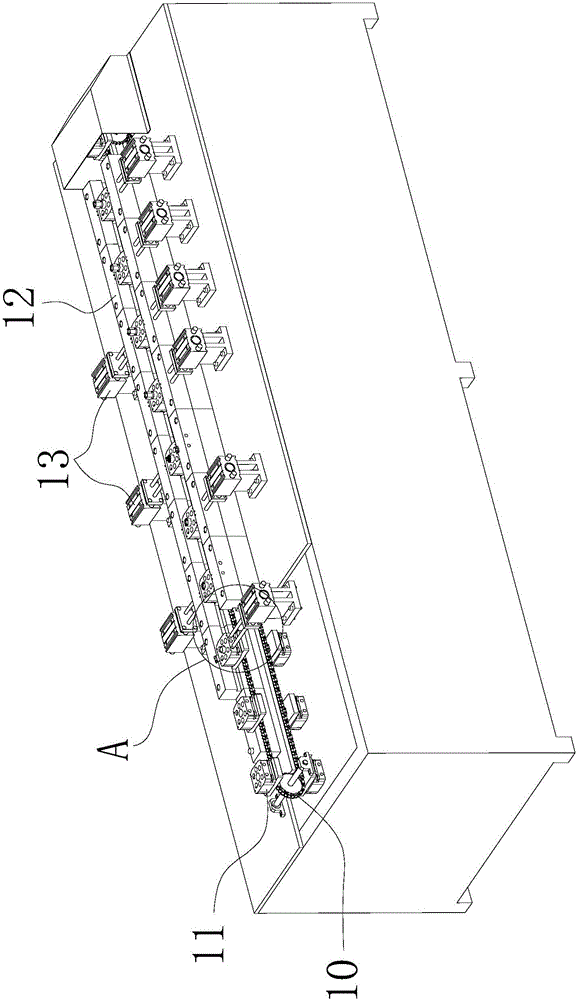

[0042] combine figure 1 , figure 2 As shown, the workpiece transmission mechanism 1 is provided with a transmission chain 10 driven by a stepping motor to rotate step by step. The entire transmission chain 10 is equidistantly equipped with workpiece clamping devices 11 for instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com