Carded blister pack

a card and blister pack technology, applied in the field of carded blister pack, can solve the problems of unintentional pack rupture and attendant product fracture impede localised or piecemeal foil and blister separation, and impede the detachment of the card, so as to facilitate the detachment. , the effect of sufficient residual mechanical robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0146] There now follows a description of some particular embodiments of the invention, by way of example only, with reference to the accompanying diagrammatic and schematic drawings, in which:

[0147] Cover Card Variants

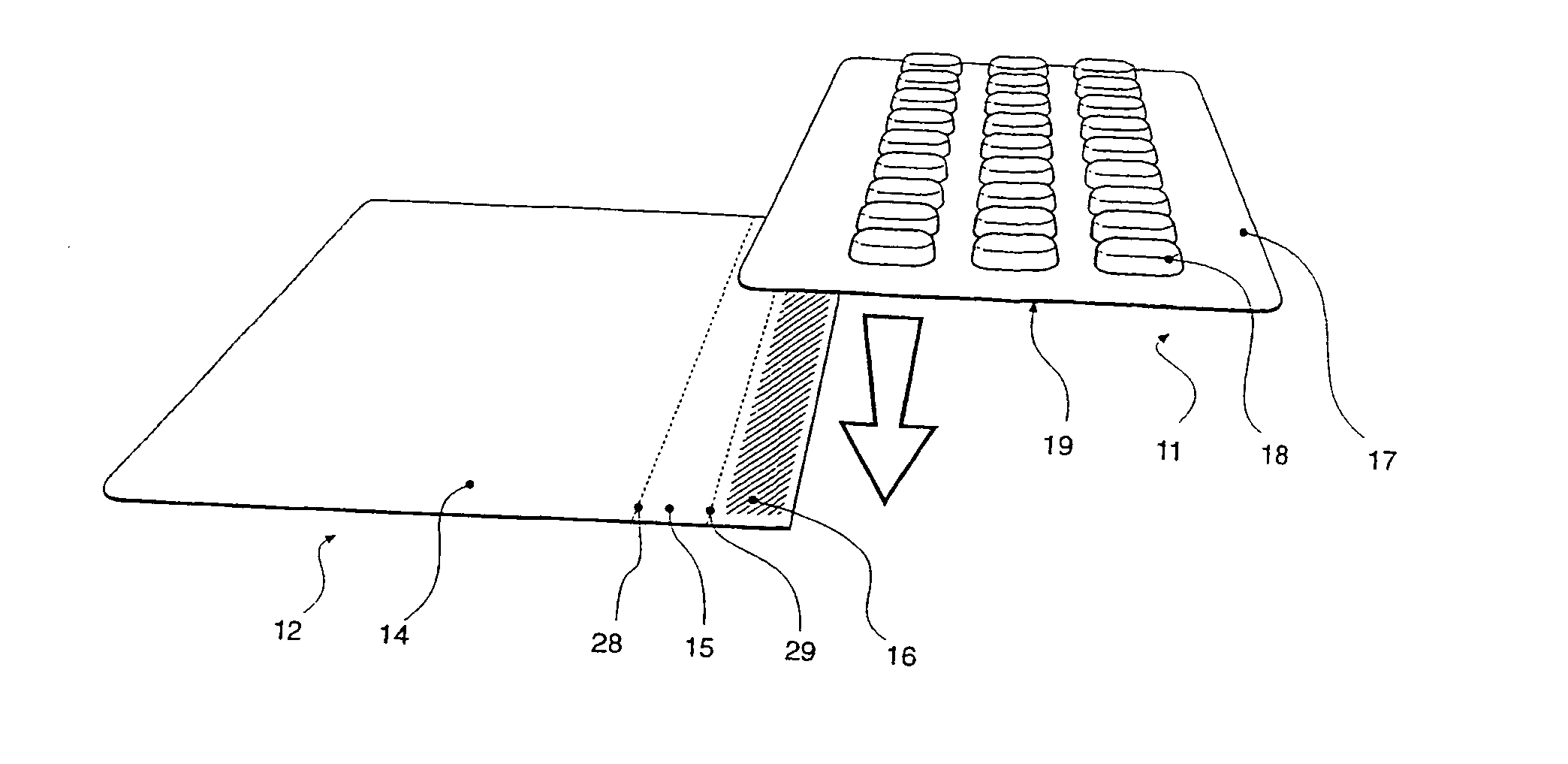

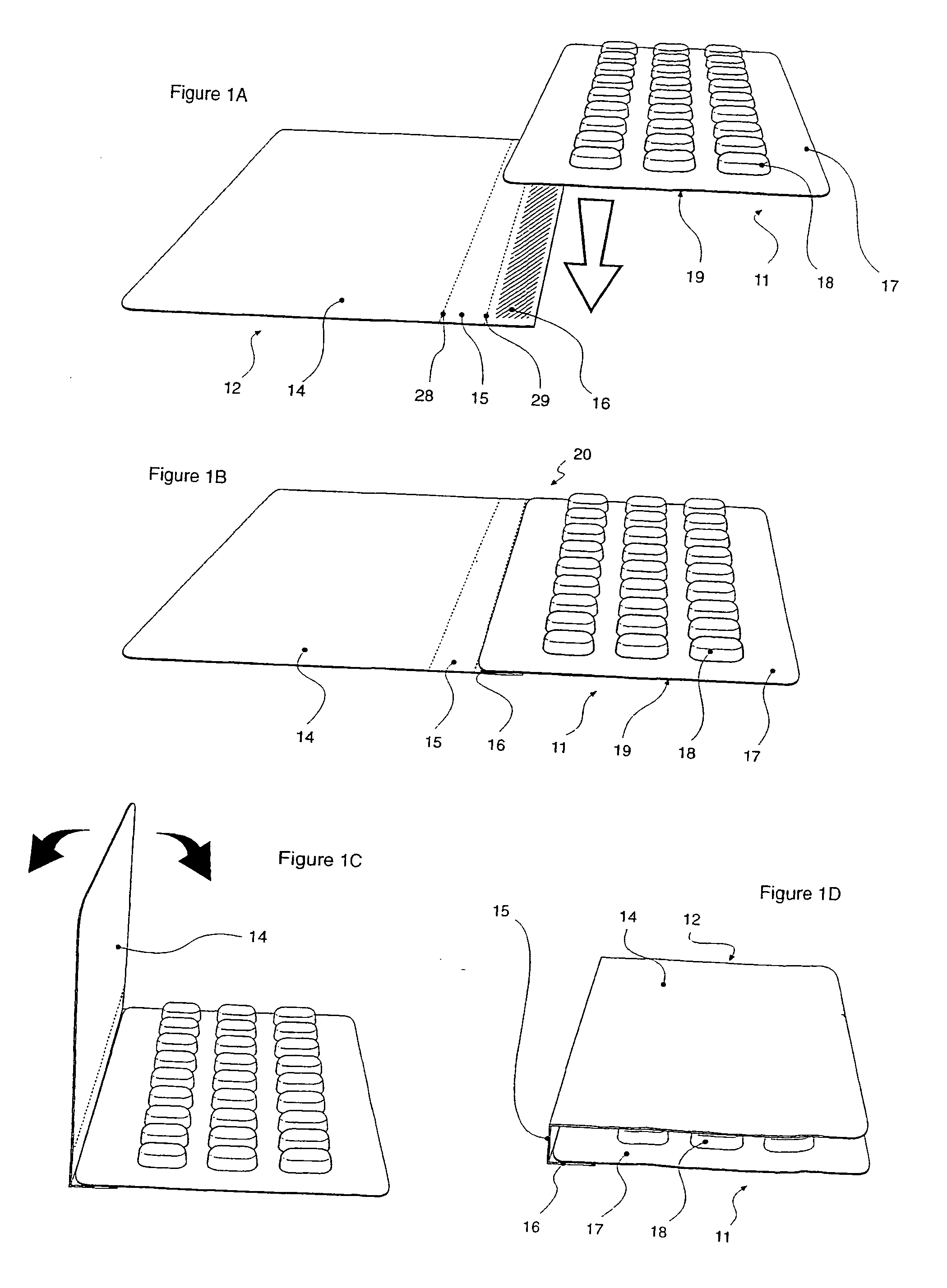

[0148] FIGS. 1A through 1D show successive assembly, folding over and closing together stages for a carded blister pack;

[0149] More specifically:

[0150] FIG. 1A shows juxtaposition of a discrete card element and a blister pack to be entrained thereby, with marginal corresponding edge overlap;

[0151] FIG. 1B shows an assembled card and blister pack, with marginal overlapped edges mutually bonded;

[0152] FIG. 1C shows an initial stage of card element folding, about a crease line, alongside a (adhesively) bonded spine portion;

[0153] FIG. 1D shows closure of the card element to overlie the blister pack, as a book, book cover (leaf) or book jacket configuration;

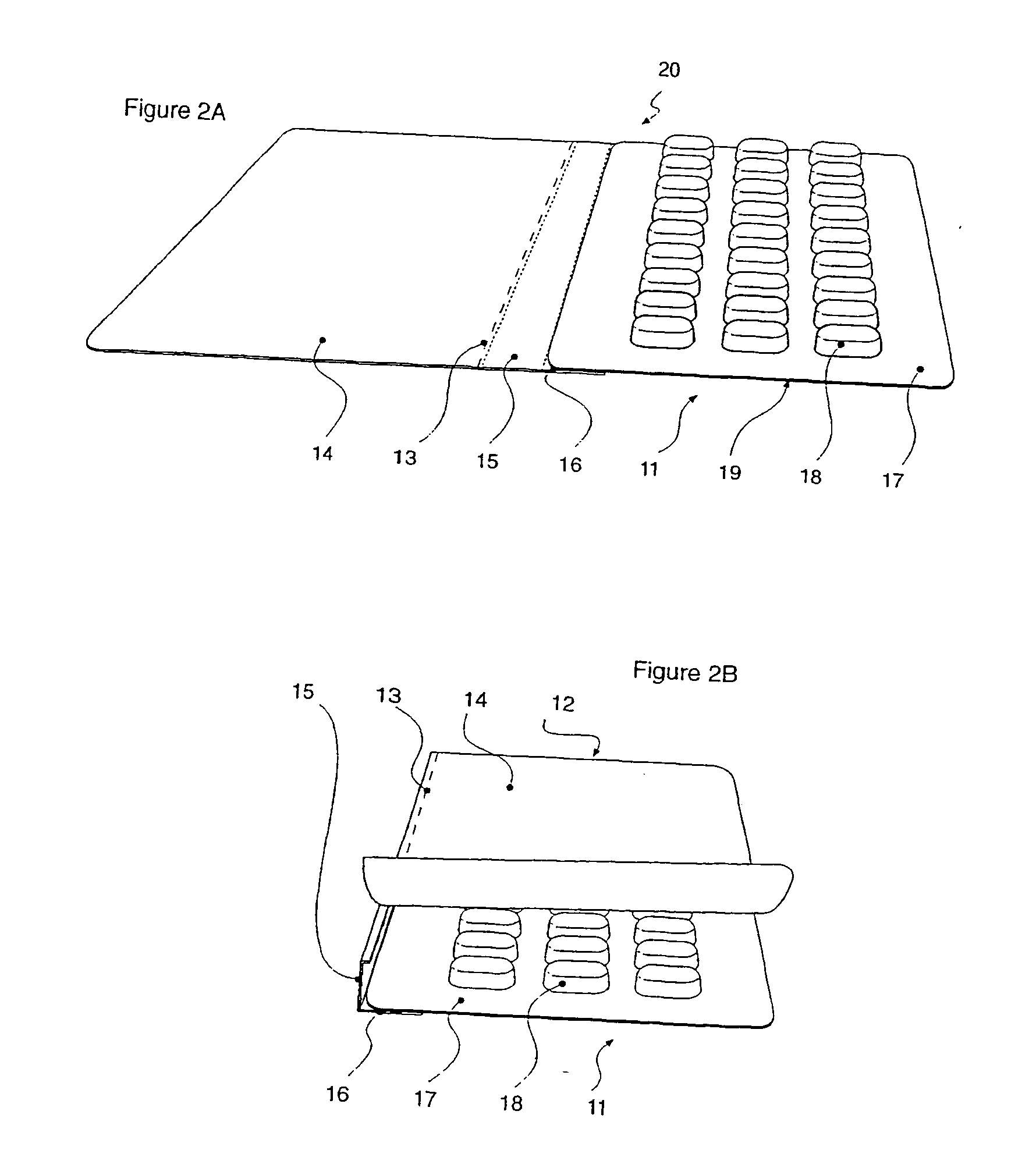

[0154] FIGS. 2A and 2B show a variant of FIGS. 1A through 1D with severable card element through a perforation line;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com