Novel tact switch assembling machine

A light touch switch and assembly machine technology, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of long running route of manipulators, inconvenient assembly and assembly, and affecting quality, so as to facilitate reciprocation, fast installation, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific examples, but the specific examples do not limit the present invention in any way.

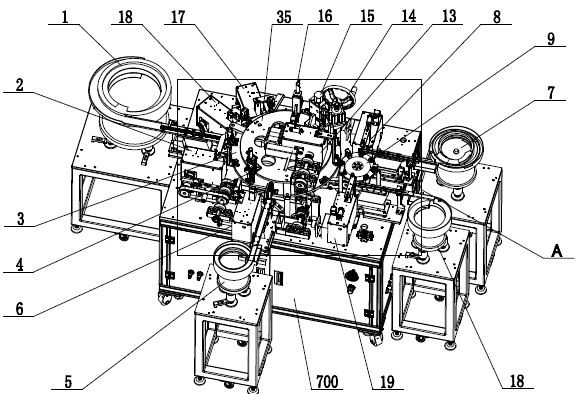

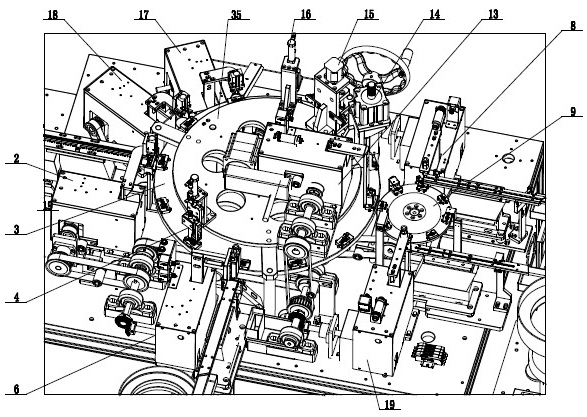

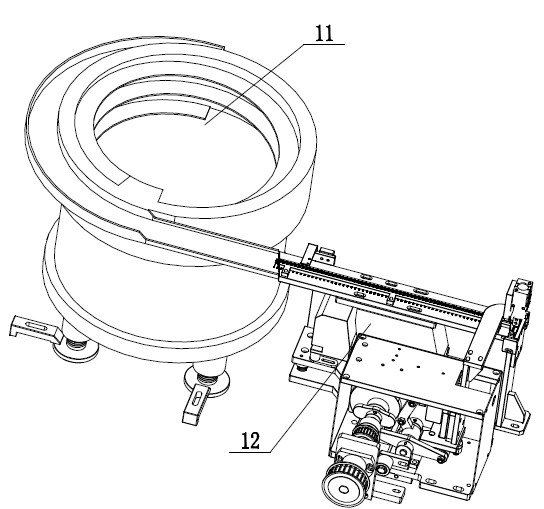

[0040] Such as figure 1 , 2 As shown, the new light touch switch assembly machine in the present invention includes: a body 700 and a large rotating disk assembly 3 and a small rotating disk assembly 9 arranged on the body 700 . Along the counterclockwise circumferential direction of the large rotating disk assembly 3, there are sequentially arranged: sending body vibration disk assembly 1, upper body manipulator assembly 2, foreign object removal assembly 4, upper shrapnel manipulator assembly 6, shrapnel sending vibration disk assembly 5, assembly manipulator assembly 13. A pressing component 14 , a CLICR detection component 15 , a conduction detection component 16 , a good product manipulator component 17 and a defective product manipulator component 18 . Among them, the assembly manipulator componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com