Full-automatic combination assembly machine for adjusting screws and nuts

A fully automatic technology for adjusting screws, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of easily affected fingers, low production efficiency of screws and nuts, and easy damage to workers, so as to improve production efficiency and improve appearance The effect of uniform quality and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings.

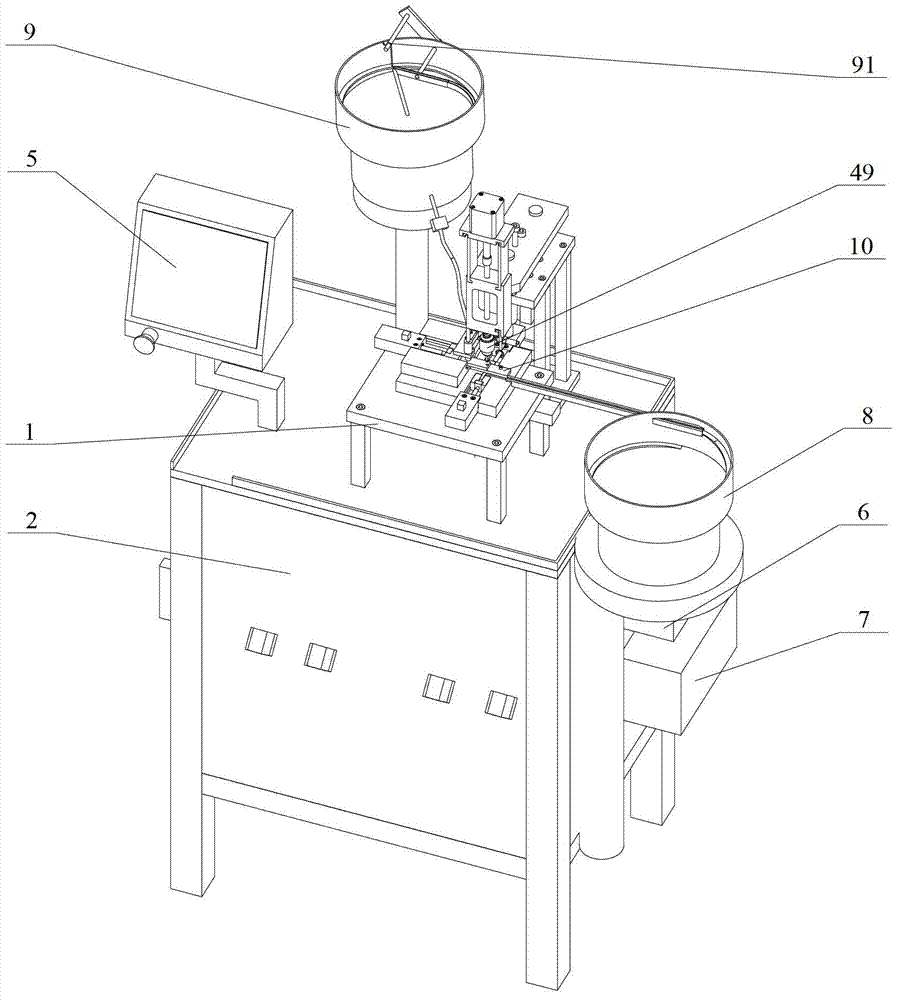

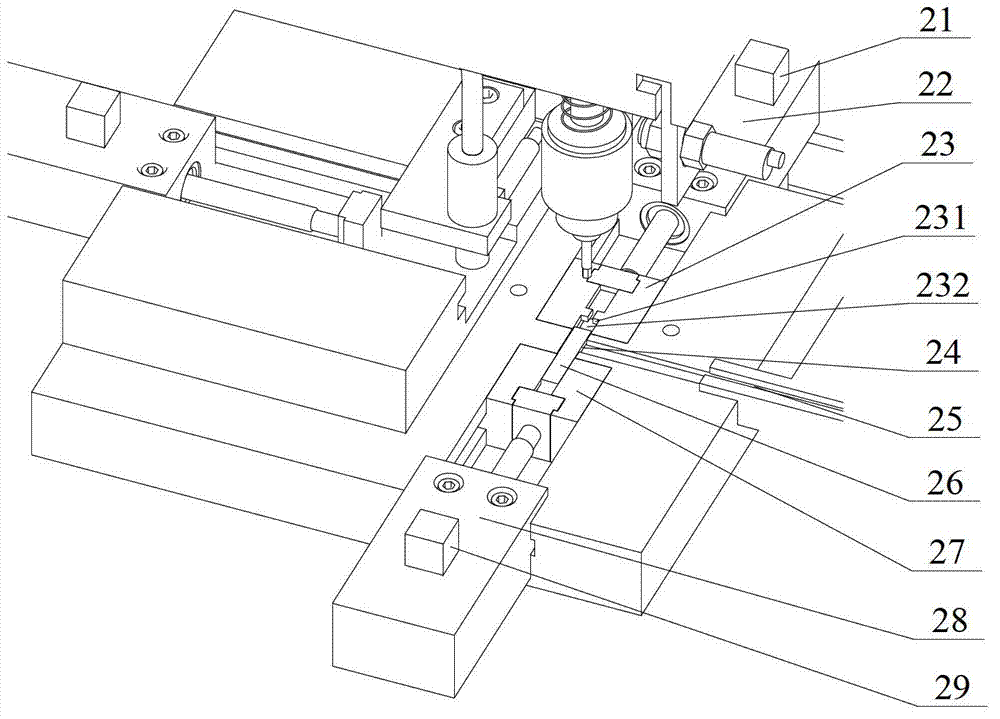

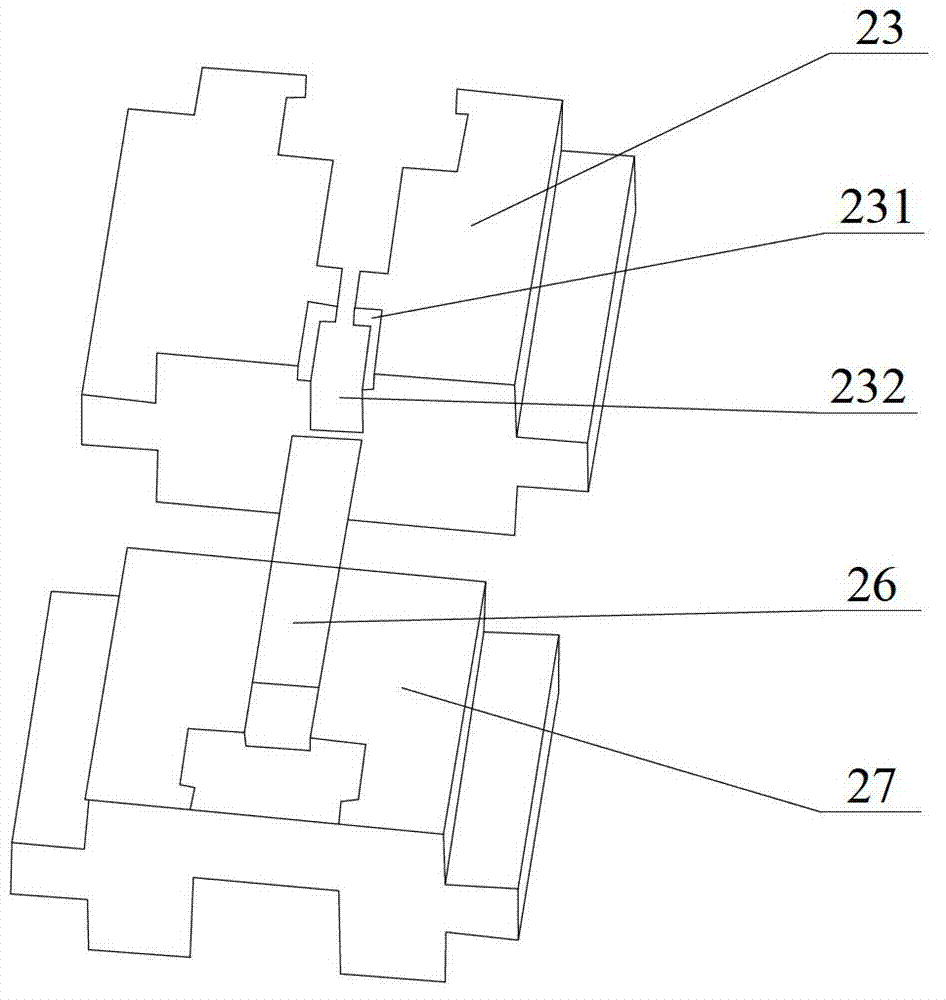

[0028] like figure 1 As shown, the fully automatic assembly machine for adjusting screws and nuts provided by the present invention includes a workbench, a nut feeding device, a screw feeding device, a lifting and spinning device, and a discharging device.

[0029] The workbench includes a lower box body 2 and an assembly table 1 fixed on the box body 2. The assembly table 1 is rectangular and is fixed in the middle of the top surface of the box body 2 through four pillars. The left side of the top surface of the box body 2 is fixed with a The control panel 5 with a touch screen, the inside of the box body 2 is provided with a control system connected to the control panel 5, the air source processor 6 and the cylinder solenoid valve 7 are fixed on the right side of the box body 2, as the nut feeding device, The power source of screw feeding device, lifting spinning de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com