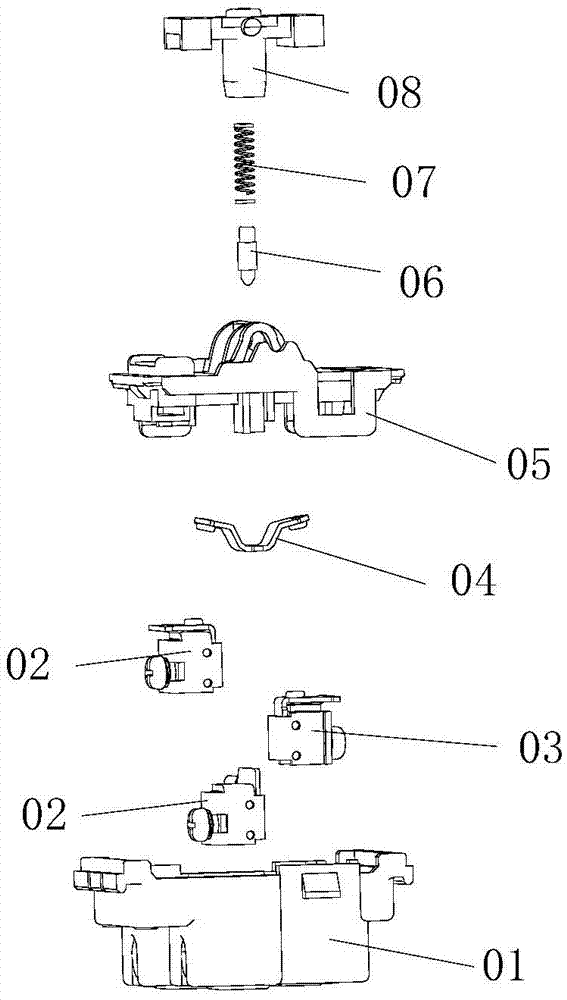

Automatic assembly machine for wall control switch

A technology of automatic assembly machine and control switch, applied in the direction of assembly machine, electric switch, manufacturing tool, etc., can solve the problems of low product qualification rate, low assembly efficiency, unstable product quality, etc., and achieve high degree of automation and high assembly efficiency. , The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is the best example of the wall control switch automatic assembly machine described in the present invention, which does not limit the protection scope of the present invention.

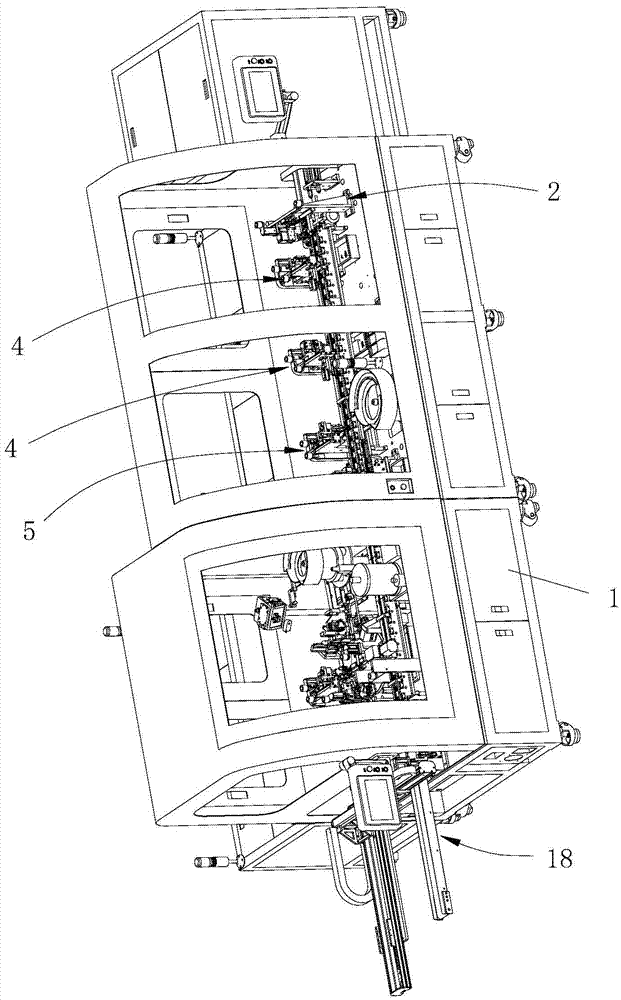

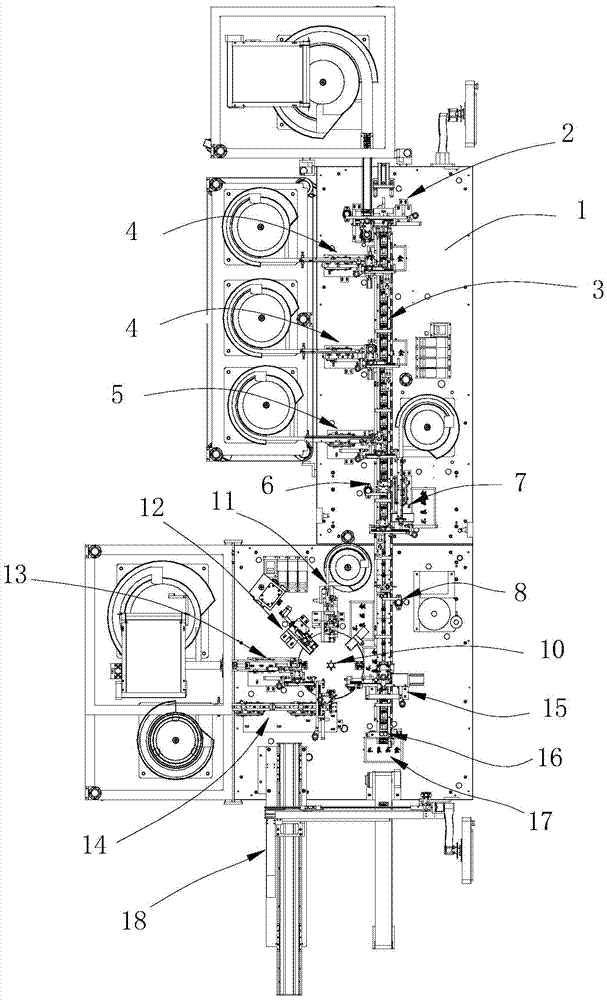

[0045] Please refer to figure 2 and image 3 , a wall control switch automatic assembly machine is shown in the figure, including a frame 1, a trough conveying device 3 is installed on the frame 1, and a base feeding mechanism for sending the switch base into the trough conveying device 3 2. One or two side terminal feed assembly mechanisms 4 for assembling the switch side terminals to the switch base, one middle terminal feed assembly mechanism 5 for assembling the middle terminals of the switch to the switch base, and one for the switch The seesaw feeding assembly mechanism 7 that the seesaw is assembled on the switch base, a turntable mechanism 10 with several clamps 9, a bullet feed mechanism 11 for placing the switch bullet on the clamp 9, and a bullet feed mechanism 11 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com