Expansion bolt automatic assembly machine

An automatic assembly machine and expansion bolt technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly efficiency, low product qualification rate, unstable product quality, etc., to achieve high assembly efficiency and improve product quality. Qualified rate and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is the best example of the expansion bolt automatic assembling machine of the present invention, which does not limit the protection scope of the present invention.

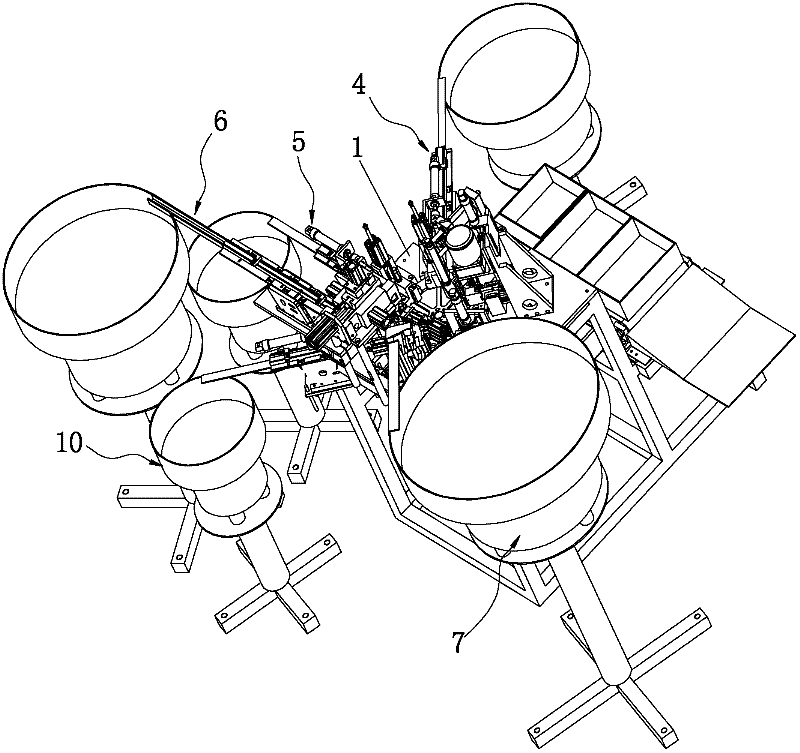

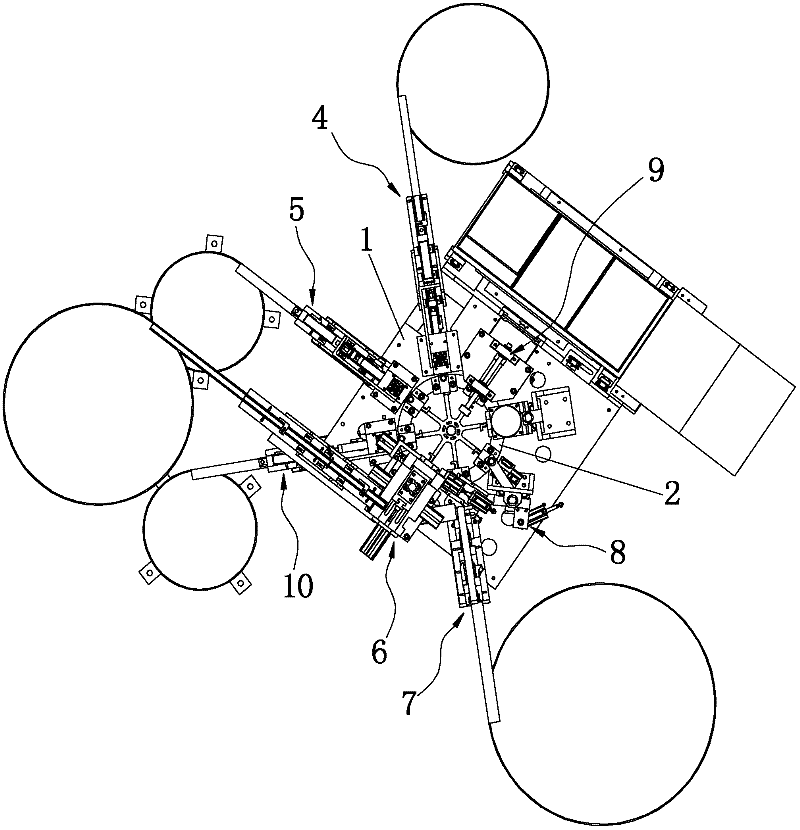

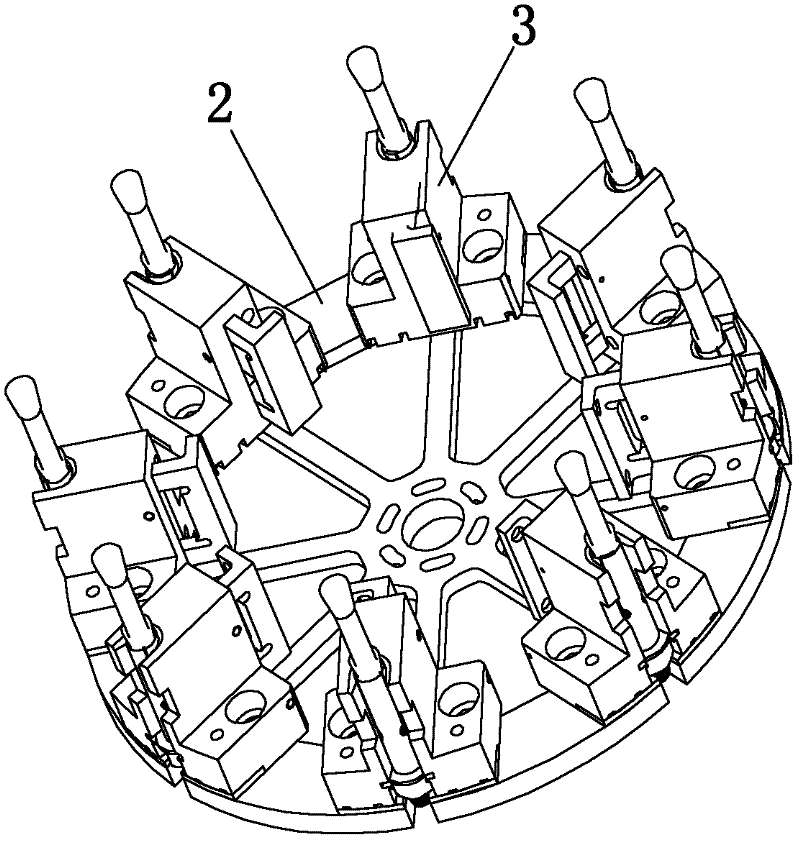

[0024] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , providing an automatic assembly machine for expansion bolts, including a frame 1, a cam divider turntable 2 arranged on the frame 1, a number of clamps 3 are arranged at intervals on the cam divider turntable 2, and a 1 on:

[0025] A nut feeding device 4 for feeding nuts into the fixture 3;

[0026] Gasket feeding device 5 for feeding the gasket into the fixture 3;

[0027] An expansion tube feeding device 6 for sending the expansion tube into the clamp 3;

[0028] A bolt feeding device 7 for feeding bolts into the fixture 3;

[0029] A rotating assembly device 8 for assembling the above-mentioned nuts, gaskets, expansion tubes, and bolts sent into the fixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com