Automatic soldering system

a soldering system and soldering technology, applied in the direction of soldering apparatus, manufacturing tools,auxillary welding devices, etc., can solve the problems of low passing rate of production, low efficiency, low quality, etc., and achieve the effect of improving product passing rate and increasing assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

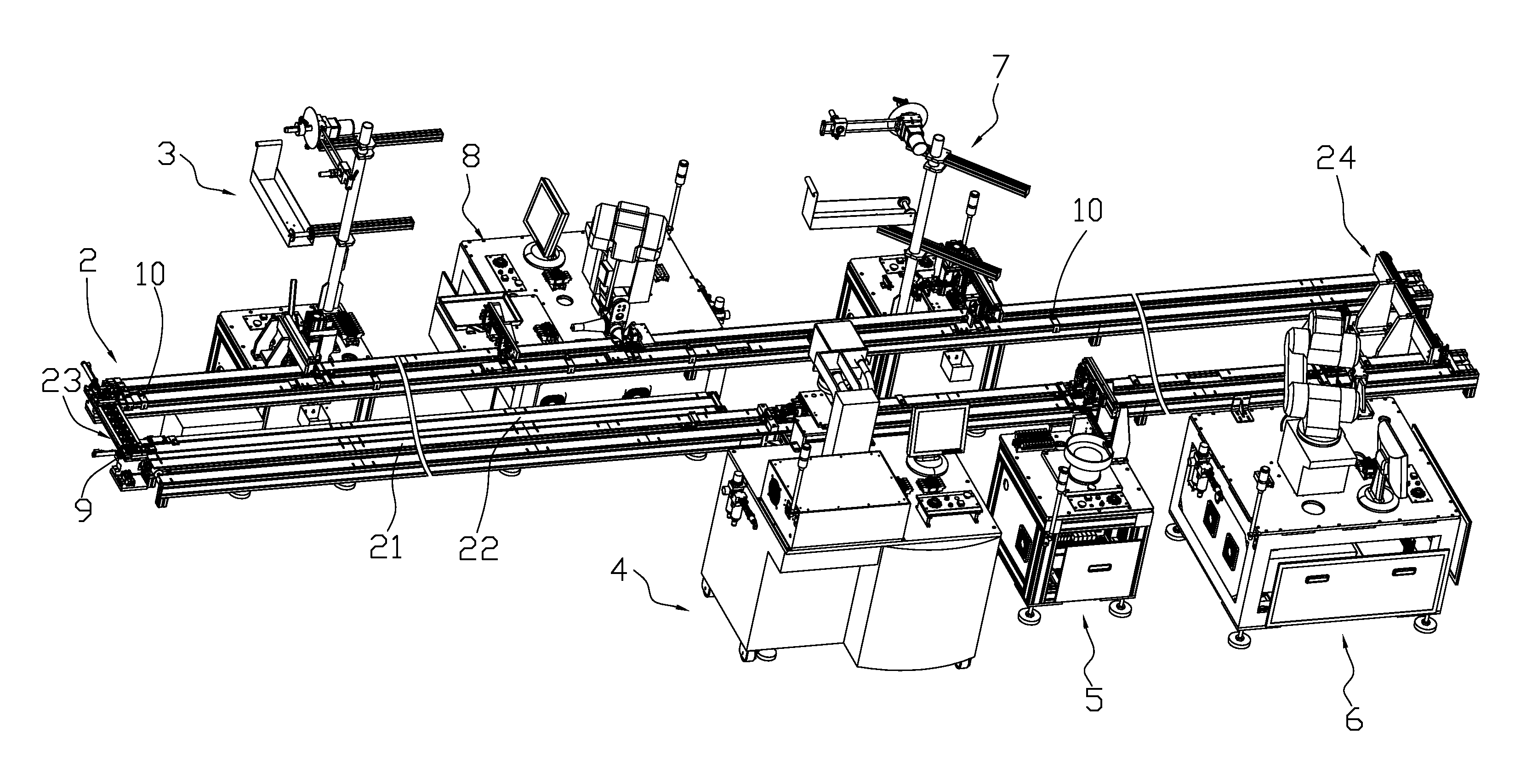

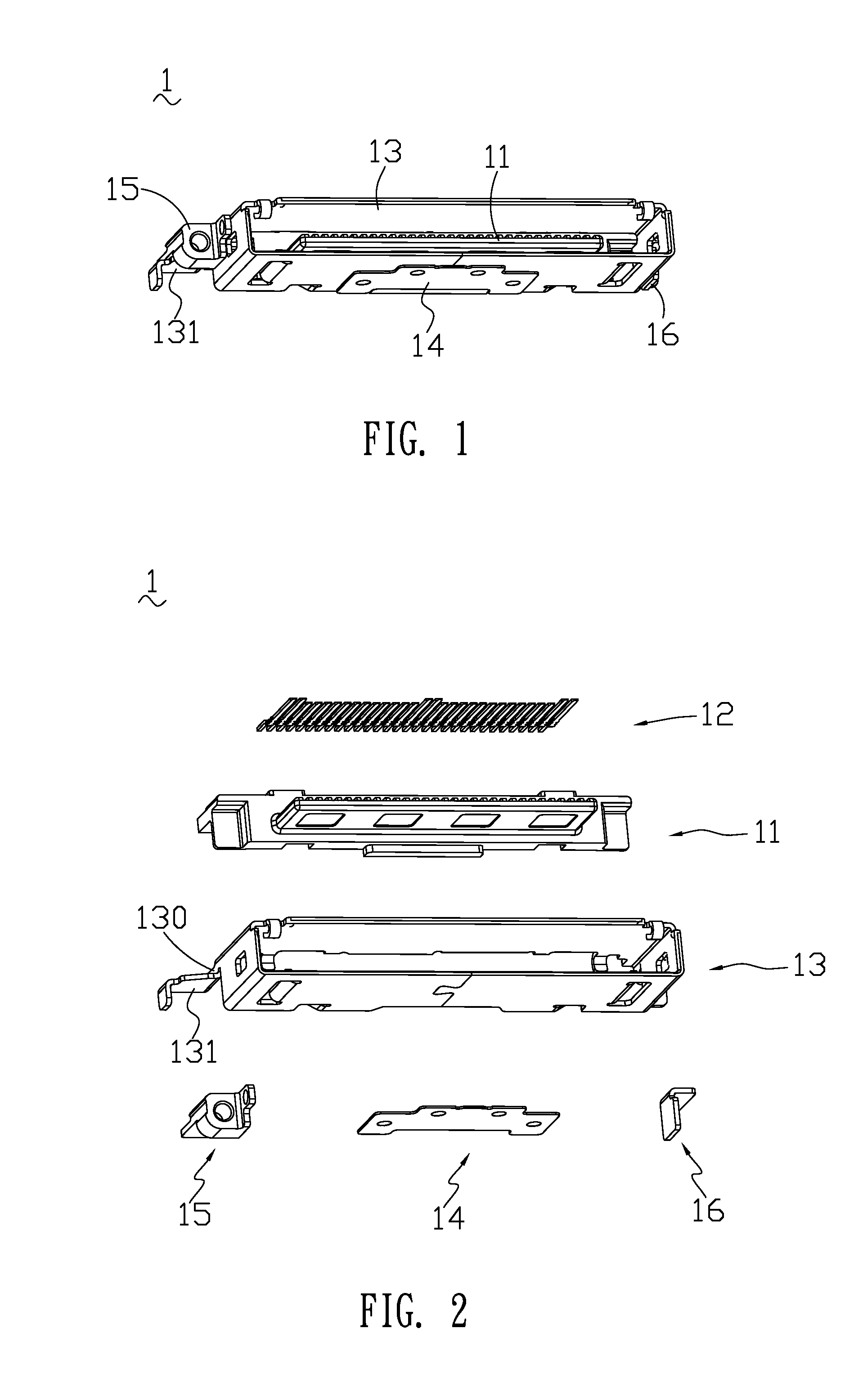

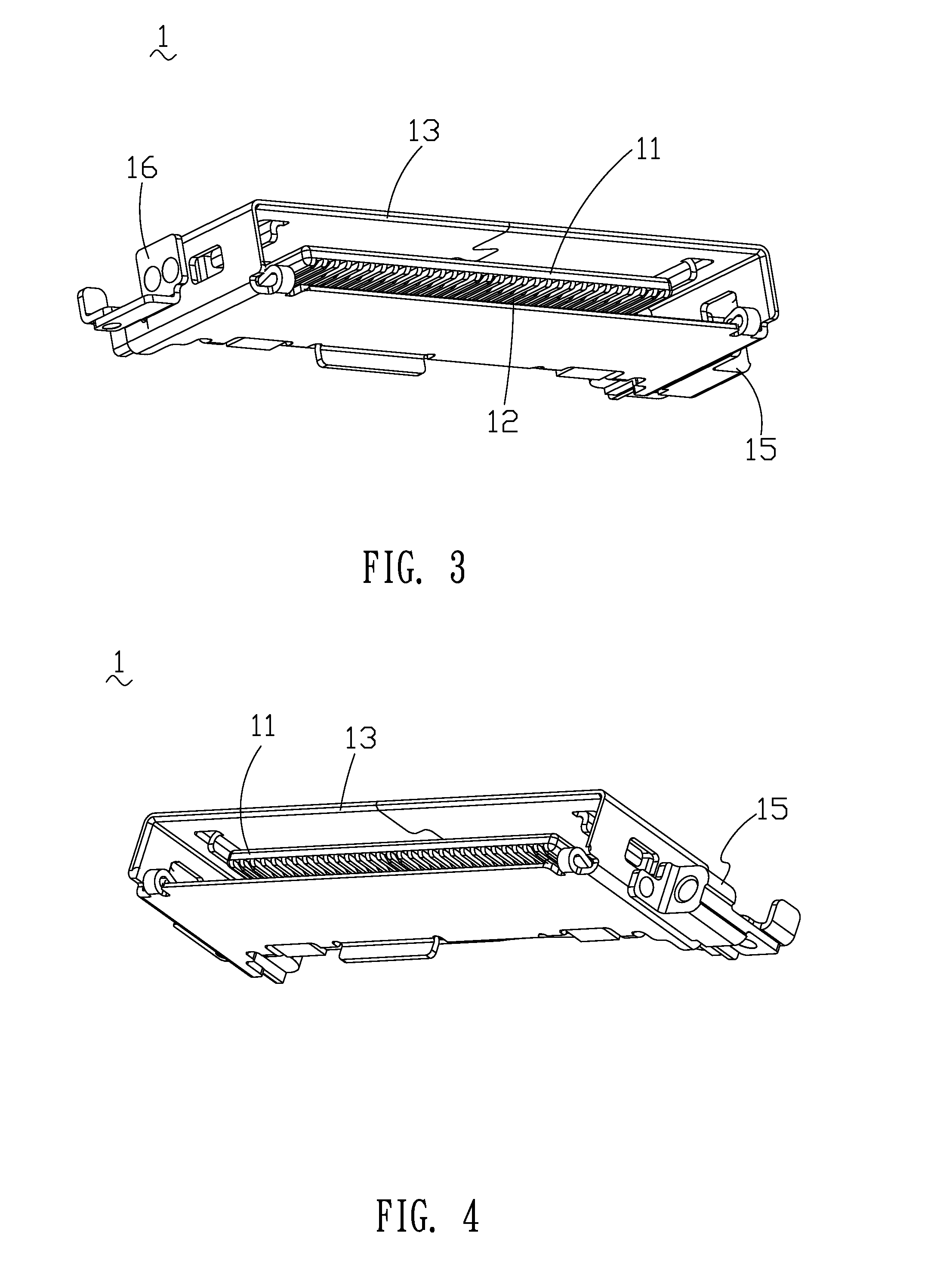

[0030]The present invention provides an automatic soldering system, which is used to solder a plurality of secondary parts to a metal shell of a primary workpiece from various directions in a manufacturing process of the primary workpiece. In the embodiment illustrated, the primary workpiece comprises an electrical connector 1. As shown in FIGS. 1-4, the electrical connector 1 comprises an insulation housing 11, a plurality of conductive terminals 12 mounted in the insulation housing 11, and a metal shell 13 enclosing the insulation housing 11. The metal shell 13 has side boards each forming an extension 130 extending rearward from a rear end of an upper portion of the side board. The two extensions 130 have lower edges from each of which a soldering tab 131 extends outward in a perpendicular manner. The metal shell 13 has a bottom surface and left and right side surfaces to which a first part 14, a second part 15, and a third part 16 are respectively soldered. In an assembling proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com