Counterpoint label, circuit board and display device

一种对位标识、电路板的技术,应用在电路板工具定位、印刷电路、印刷电路等方向,能够解决无法满足电路板窄边化要求、降低电路板利用率等问题,达到满足窄边化、提高利用率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

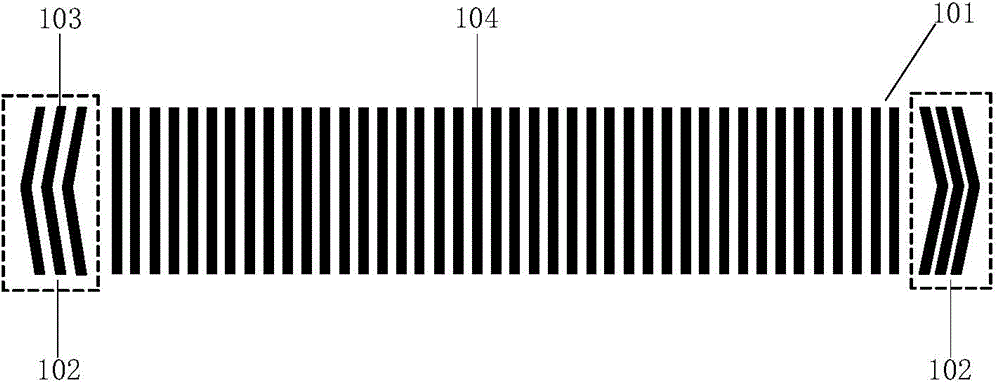

[0023] image 3 It is a schematic structural diagram of an alignment mark provided by Embodiment 1 of the present invention. Such as image 3 As shown, the alignment mark 102 is set on the binding area 101, and the alignment mark 102 is used to locate the parts to be bound during the binding process, and the alignment mark 102 is set on the parts to be bound The first gold finger 103 on the top constitutes. A plurality of second golden fingers 104 spaced apart from each other are also arranged on the binding area 101 . Optionally, there are two alignment marks 102 in one binding area 102, wherein one alignment mark 102 is set at one end of the binding area 101, and the other alignment mark 102 is set at the end of the binding area 101. The other end of the binding area 101.

[0024] In practical applications, the components to be bound include flexible circuit boards or printed circuit boards. Gold Finger (Gold Finger) is the interface between the circuit of the printed c...

Embodiment 2

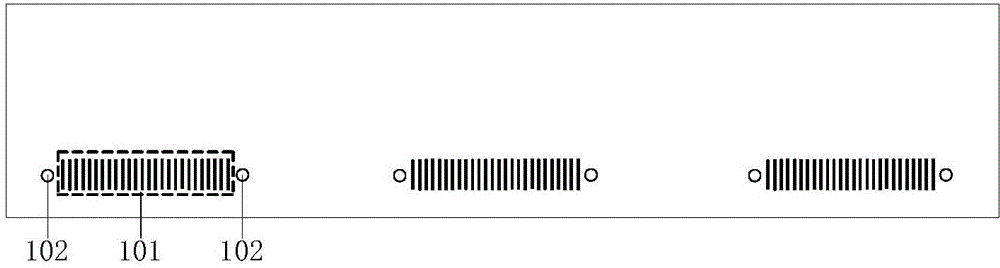

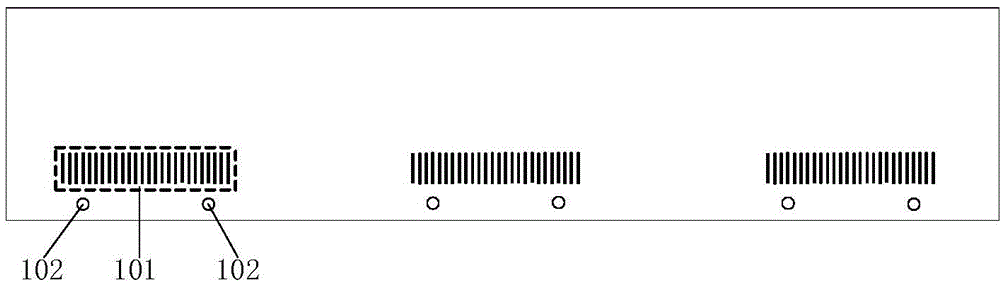

[0028] Figure 5 It is a schematic structural diagram of a circuit board provided by Embodiment 2 of the present invention. see image 3 and Figure 5 , the circuit board includes a substrate 105, and the substrate 105 is provided with a binding area 101, and the binding area 101 is provided with the alignment mark 102 provided in the first embodiment. The alignment mark 102 is used for positioning the components to be bound during the binding process, and the alignment mark 102 is composed of a first golden finger 103 arranged on the components to be bound. A plurality of second golden fingers 104 spaced apart from each other are also arranged on the binding area 101 . Optionally, there are two alignment marks 102 in one binding area 102, wherein one alignment mark 102 is set at one end of the binding area 101, and the other alignment mark 102 is set at the end of the binding area 101. The other end of the binding area 101.

[0029] In practical applications, the compone...

Embodiment 3

[0033] This embodiment provides a display substrate, including the circuit board provided in Embodiment 2. For specific content, refer to the description in Embodiment 2 above, which will not be repeated here.

[0034] In the display device provided in this embodiment, the alignment mark is used to position the component to be bound during the binding process, and the alignment mark is formed by a first golden finger arranged on the component to be bound. The alignment mark provided by this embodiment is set in the binding area without additionally occupying the effective area of the circuit board, so that more components can be placed on the circuit board, thereby improving the utilization rate of the circuit board and meeting the requirements of narrowing the circuit board Require.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com