Method for manufacturing pairing marks of CF substrate

A production method and group marking technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of low recognition of materials, only leftovers, and inability to provide clear alignment references in the process, so as to improve recognition and improve optical quality. effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the technical processing adopted by the present invention and its effects, the following is a detailed description in conjunction with preferred embodiments of the present invention and accompanying drawings.

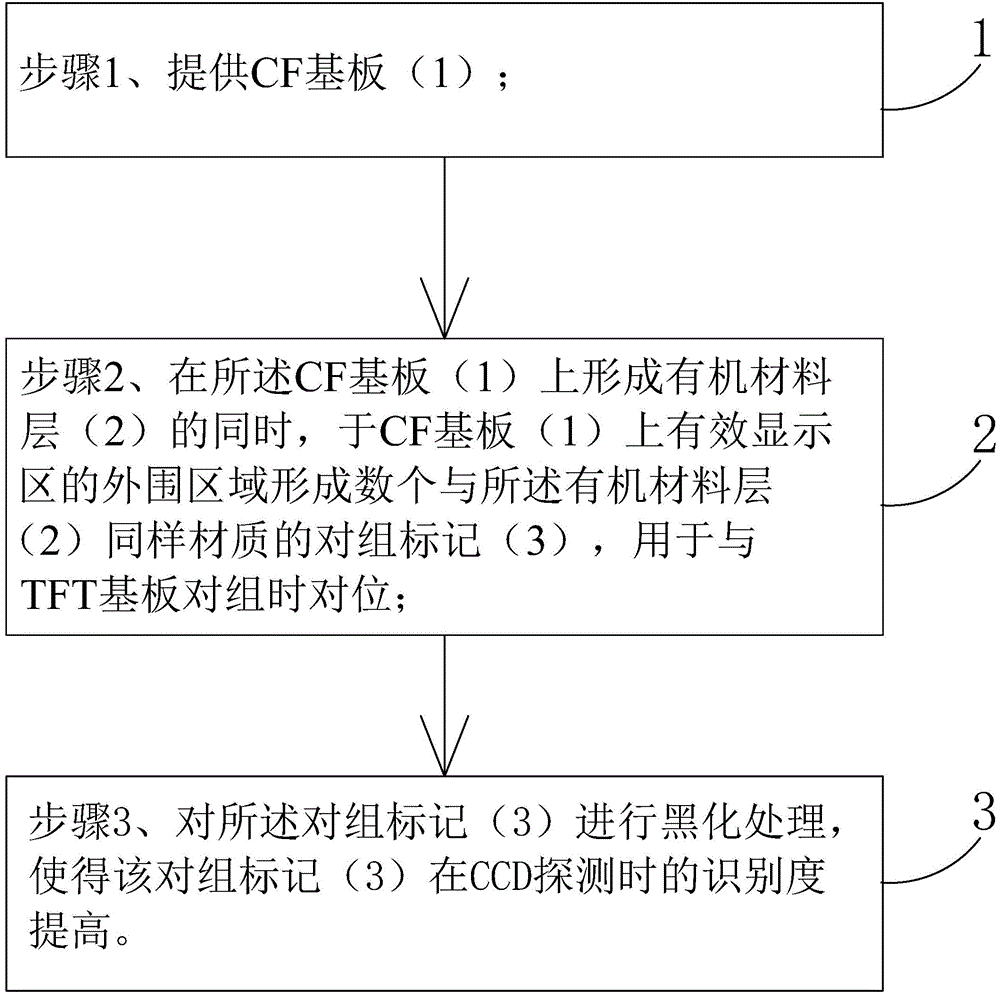

[0031] see Figure 2 to Figure 7 , the present invention provides a method for making a group mark on a CF substrate, comprising the following steps:

[0032] Step 1, providing a CF substrate 1 .

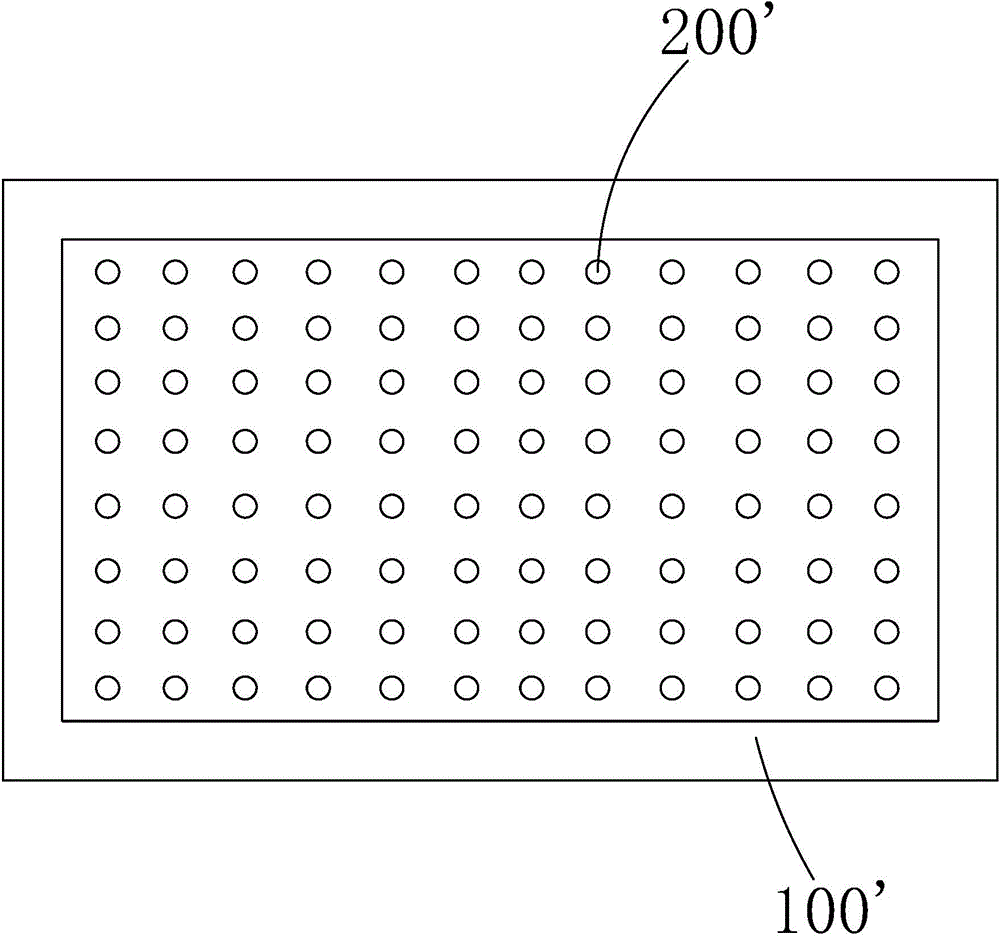

[0033] The CF substrate 1 is a CF substrate in a BOA structure liquid crystal display panel. Since the BOA structure liquid crystal display panel manufactures the black matrix on the TFT substrate, the CF substrate 1 in step 1 does not have materials with high optical density, nor does it have the same group marks as the traditional structure liquid crystal display panel.

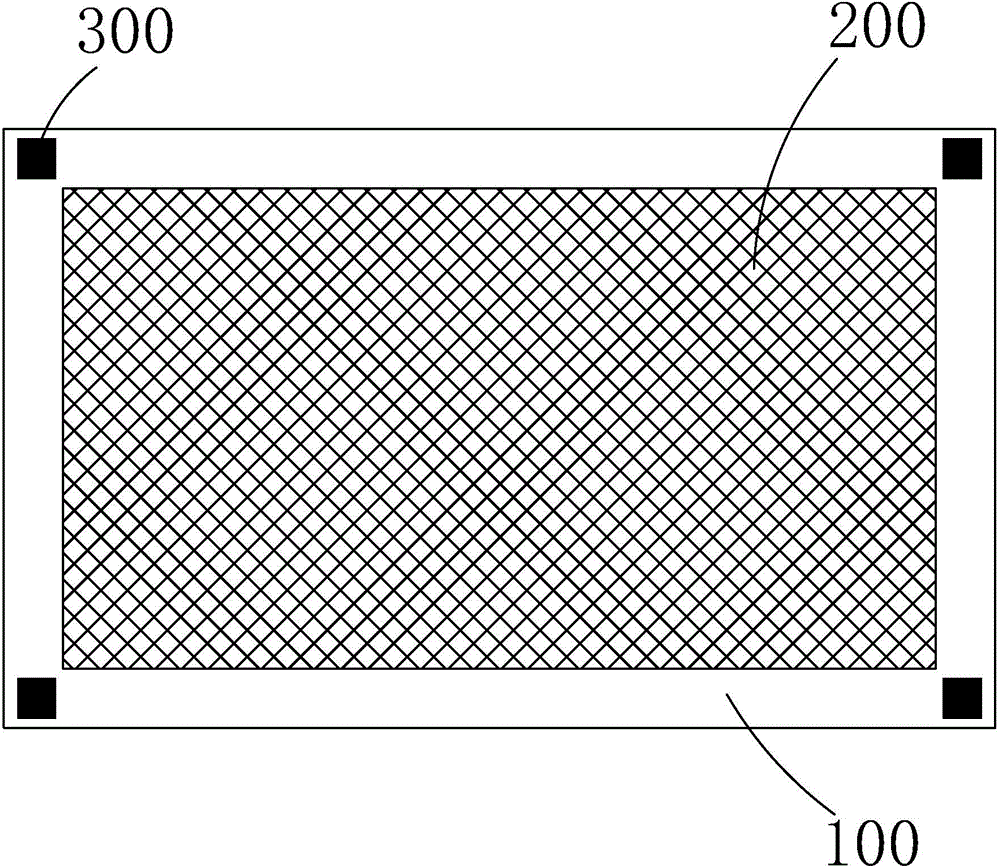

[0034] Step 2, such as Figure 4 As shown, while the organic material layer 2 is formed on the CF substrate 1 , several paired marks 3 of the same material as the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com