Method for making metal mother board

A production method and metal technology, which is applied in the copying and printing of printing plates, and can solve the problems of reduced efficiency, easy breakage, and low electroforming strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

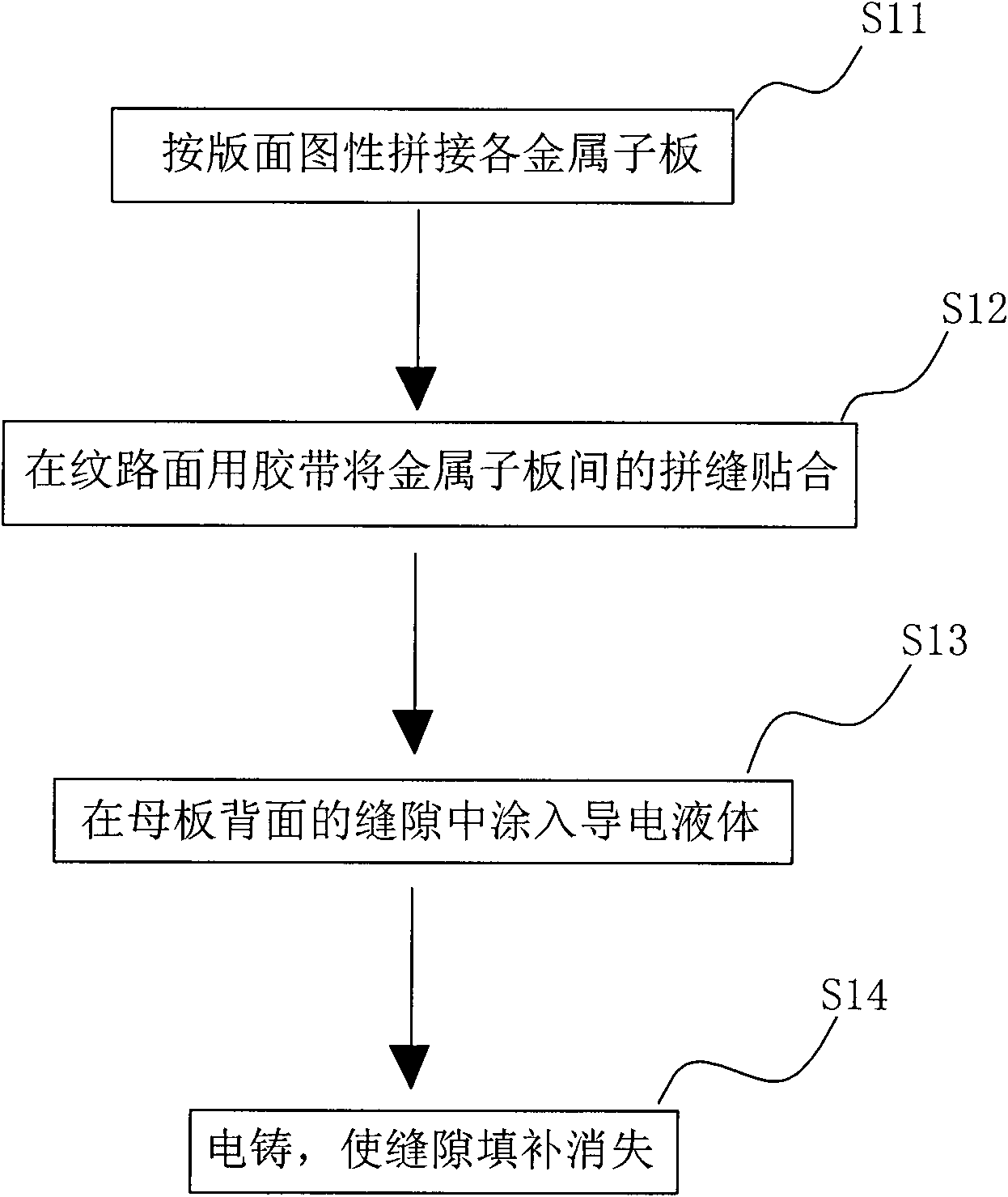

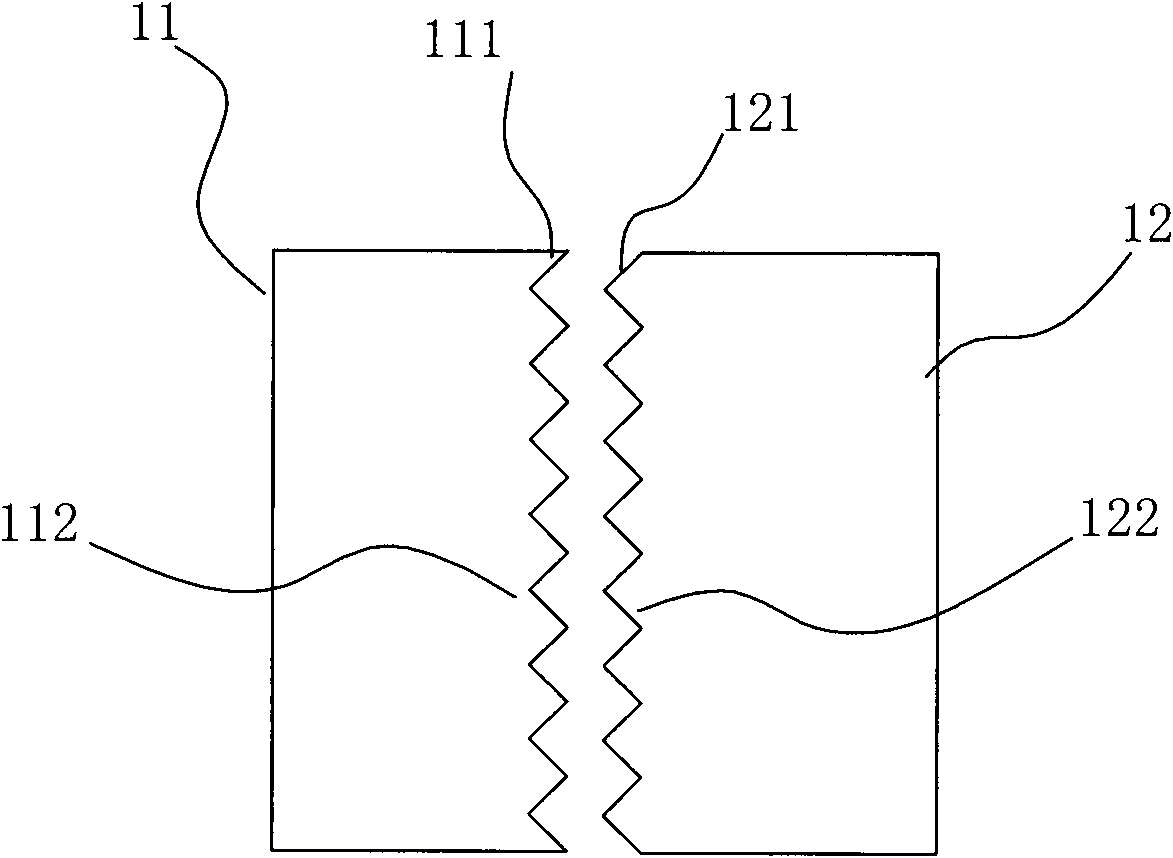

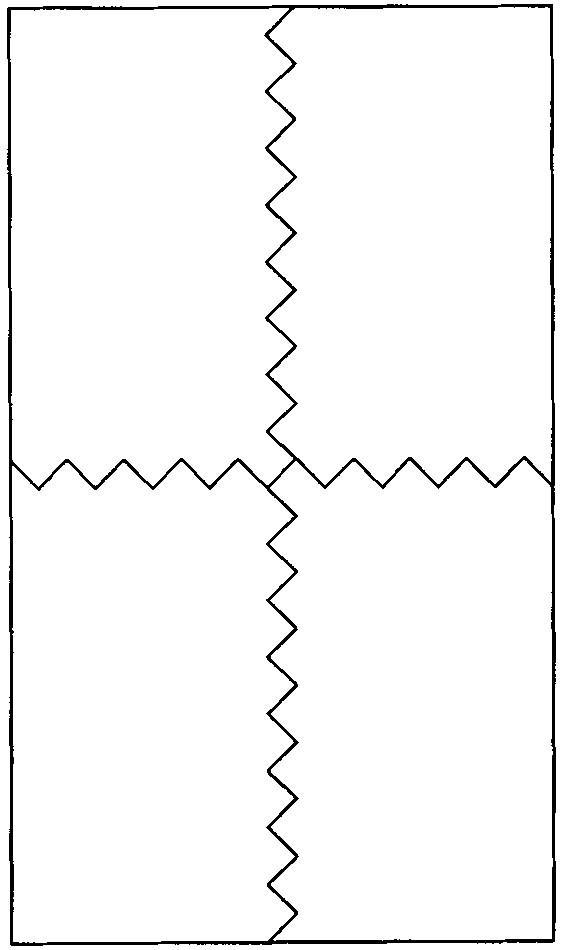

[0023] Please refer to figure 1 , figure 1 It is a flow chart of making a metal mother plate according to the first embodiment of the present invention. As shown in the figure, the first is step S11: splicing the pre-fabricated metal sub-boards according to the layout pattern of the mother board to be made. The splicing action is best carried out on a flat table, because for metal sub-boards, the thickness is often only a few tens of microns, and the thickness difference between different metal sub-boards is also less than 10um, so for splicing flat Degree requirements are very high.

[0024] Then step S12: After the splicing is completed, with the texture facing upward, use adhesive tape to fit and fix the seams on the texture surface, so that the metal sub-plates are not easy to separate, and a large-sized metal mother board with gaps is formed. The tape used is preferably acid-resistant, alkali-resistant, and high-temperature-resistant tape to avoid corrosion by the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com