Preparation method of high-low frequency hybrid-voltage printed circuit board

A printed circuit board, high and low frequency technology, which is applied in the field of preparation of high and low frequency mixed-press printed circuit boards to achieve the effects of reducing material consumption, reducing destructive testing, and improving alignment

Inactive Publication Date: 2012-12-05

UNIV OF ELECTRONIC SCI & TECH OF CHINA

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

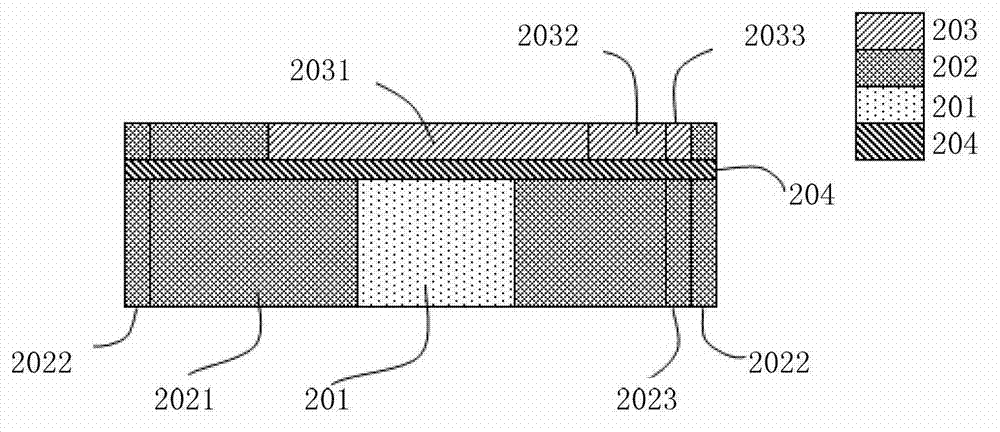

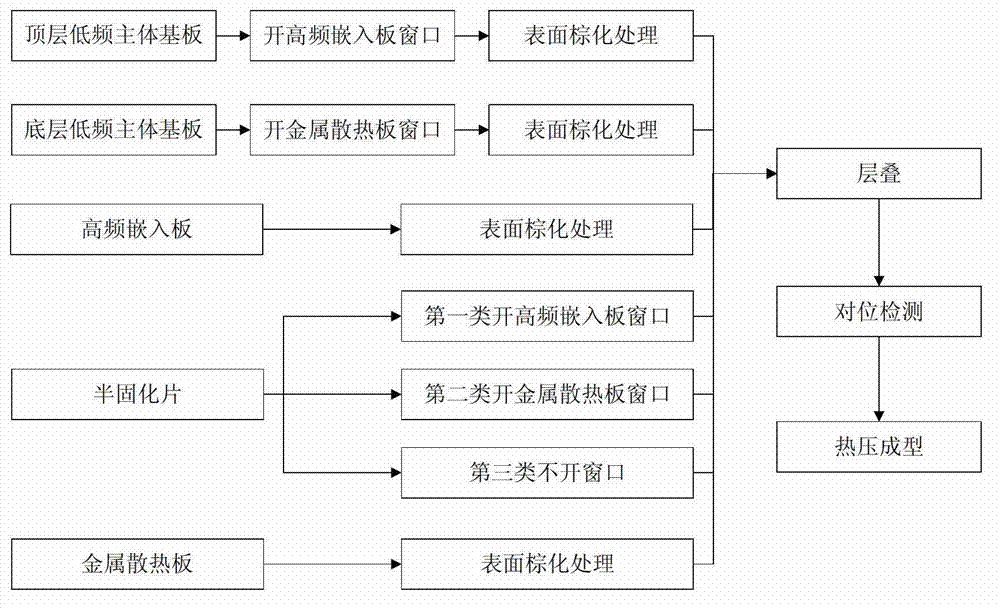

[0004] The invention provides a method for preparing a high-low frequency mixed-pressure printed circuit board. The method is to embed a high-frequency embedding plate on the top layer of the low-frequency main substrate, and embed a metal heat dissipation plate on the bottom layer of the low-frequency main substrate through process edge riveting and positioning. It solves the problem of the alignment between the main substrate and the high-frequency embedded board, reduces the destructive inspection after the low-frequency main substrate and the high-frequency embedded board are laminated, and the obtained multi-layer board meets the requirements of high-frequency circuit design and local high heat dissipation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0022] It is the same as the foregoing technical solutions, and will not be repeated here. However, all other implementations obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

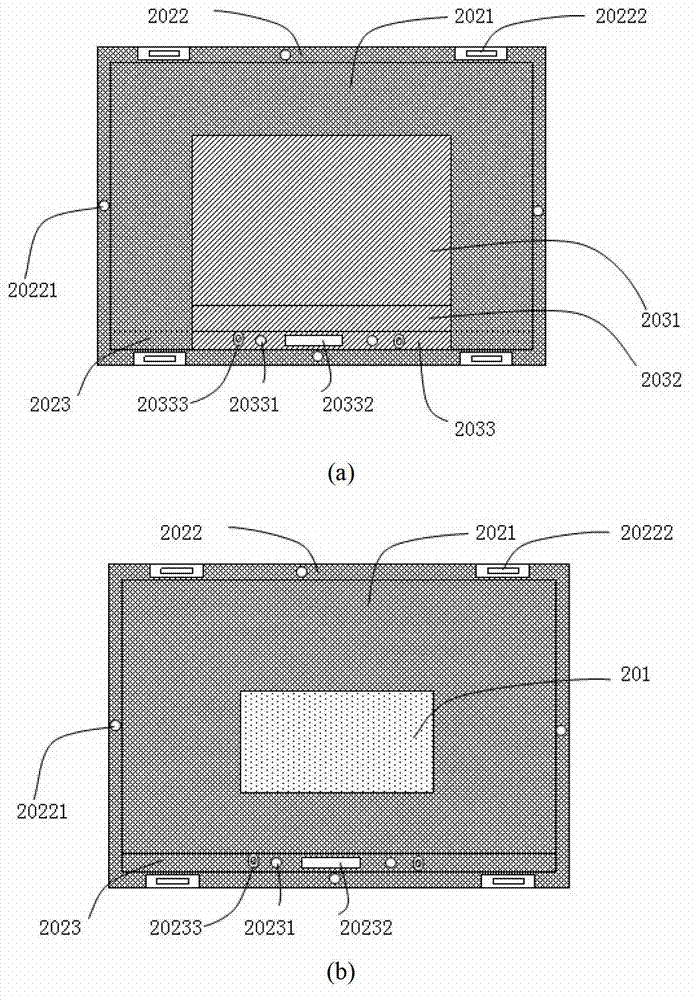

The invention discloses a preparation method of a high-low frequency hybrid-voltage printed circuit board, belonging to the technical field of printed circuit board manufacturing. The method comprises the step of adding counterpoint edges 2023 and 2033 on a low-frequency main body substrate 202 and a high frequency embedding board 203, wherein acounterpoint detecting holes and alignment testing rectangular windows are respectively formed at the added counterpoint edges. The alignment of the low frequency main body substrate with the high frequency embedding board is improved greatly, the destructive detection to the low frequency main body substrate and the high frequency embedding board after being laminated is reduced, and meanwhile the material quantity of the high frequency embedding board is reduced.

Description

technical field [0001] The invention belongs to the technical field of printed circuit board manufacturing, and relates to a high-low frequency mixed voltage printed circuit board, especially a preparation method of a high and low frequency mixed voltage printed circuit board with good heat dissipation performance. Background technique [0002] The development trend of miniaturization, high density and multi-function of electronic information products requires to improve the signal transmission speed (frequency) and heat dissipation performance of Printed Circuit Board (PCB). The materials used in traditional high-frequency PCB manufacturing are relatively expensive, which is not conducive to the popularization of high-frequency signal designs with high electrical performance in civilian electronic information products. The outer layer of the multi-layer circuit board is mixed with high-frequency board or a small piece of high-frequency board is embedded in the outer core bo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H05K3/00

Inventor 何为李瑛陈苑明王守绪陶志华

Owner UNIV OF ELECTRONIC SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com