Positioning method in novel silk screen printing CCD (charge coupled device) image identification

A technology of image recognition and positioning method, which is applied to screen printing machines, printing machines, printing machines, etc., can solve problems affecting printing accuracy and achieve high-precision alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

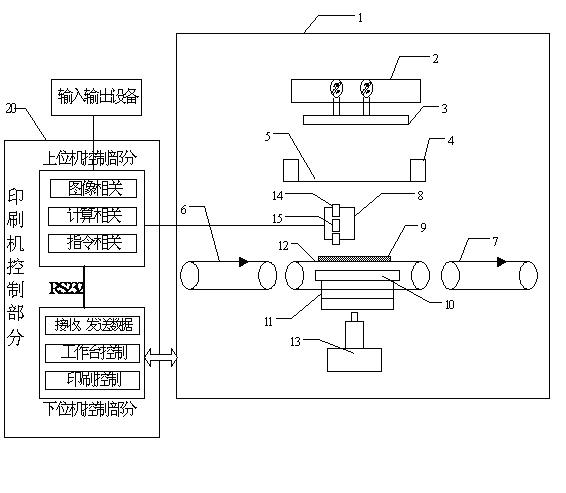

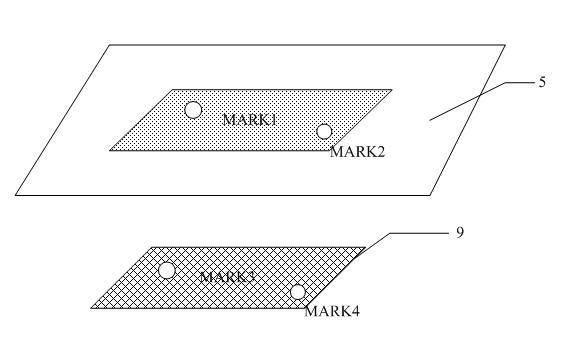

[0016] Such as figure 1 Shown is the structural schematic diagram of the whole screen printing device. exist figure 1 Shown in 1 is the mechanical structure, 20 is the control part, and the control is divided into upper computer (PC) control and lower computer (PLC) control. The upper computer provides the human-computer interaction interface and image processing and the calculation of the position deviation of the MARK point; the lower computer accepts the instructions of the upper computer to drive the relevant movements of the mechanical parts. The adopted structure is that the transmission part has three parts: the incoming part 6, the workbench transmission part 12, and the outgoing part 7. The workbench part 10 has main functions of positioning the PCB board 9 and the workbench lifting part 13 . Image acquisition device 8, its main components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com