Bridge segment lifting device and method

A hoisting device and hoisting device technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of lack of site and conditions, section transportation, and hoisting difficulties, and achieve the effect of avoiding a large number of complicated aerial operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given hereby, and the details are as follows:

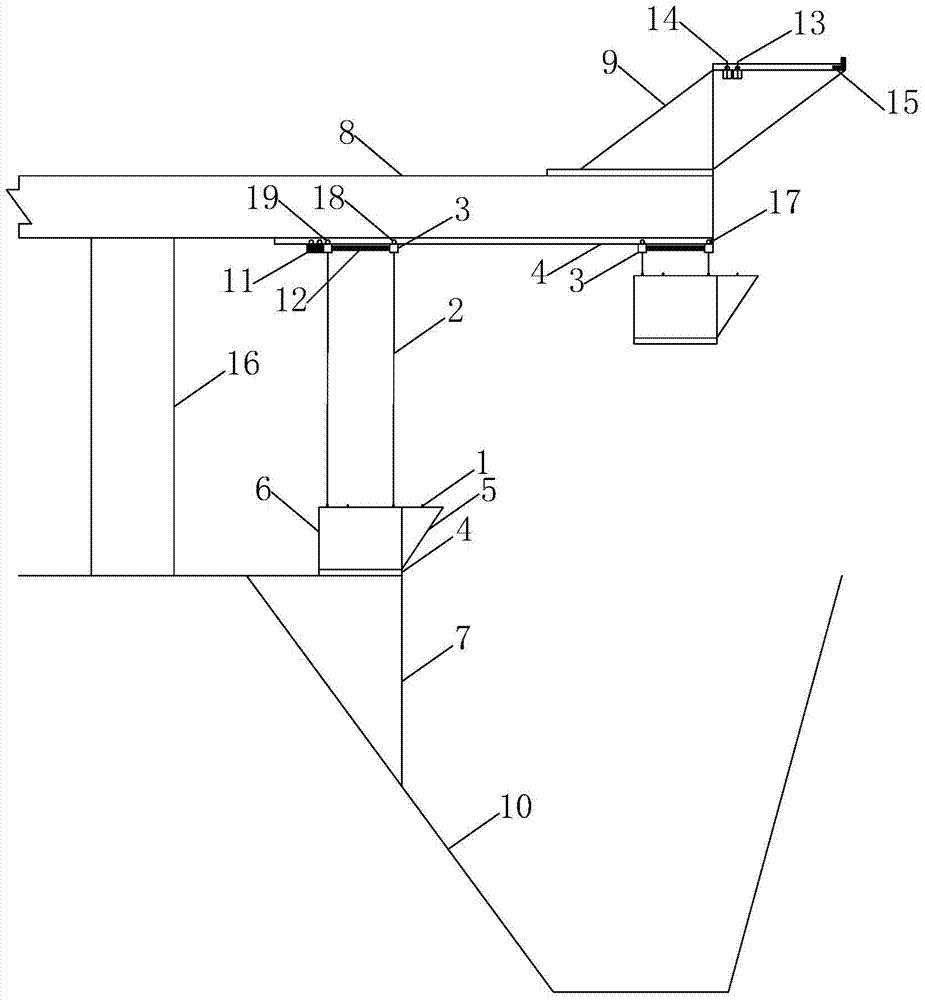

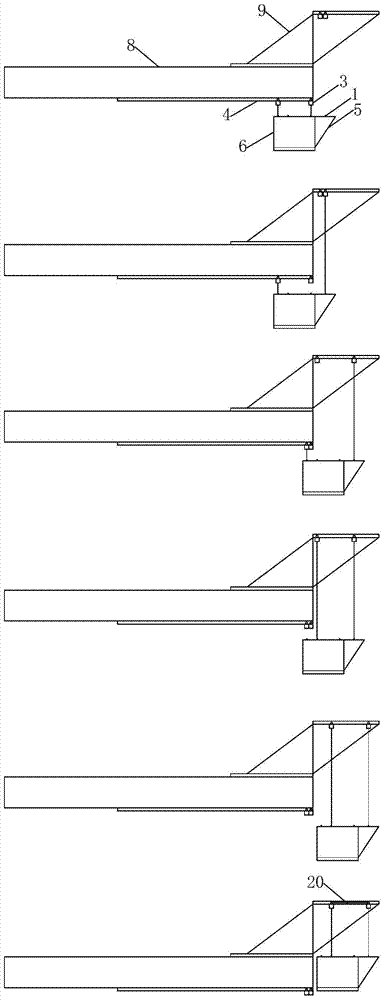

[0023] Such as figure 1 as shown,

[0024] A bridge segment hoisting device, comprising a beam top hoisting device positioned at the top of the erected beam section 8 and a beam bottom hoisting device positioned at the bottom of the erected beam section, the beam bottom hoisting device includes a lower traveling track 4, and the lower traveling track is provided with The front wheel pair 18 and the rear wheel pair 19 are detachably provided with rigid connectors 12 between the front and rear wheel pairs, and the front wheel pair and the rear wheel pair are provided with lifting devices. The hoisting device includes a steel wire rope 2 and a winch 3; the rear wheel pair is provided with a power group 11 that can move along the track.

[0025] The beam top hoisting device includes a section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com