Reverse electric conduction structure of double-surface solar cell based on PERC and manufacturing method

A technology of double-sided solar cells and conductive structures, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as low photoelectric conversion efficiency, improve photoelectric conversion efficiency, improve the ability to export photogenerated carriers, and reduce heat The effect of loss on power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

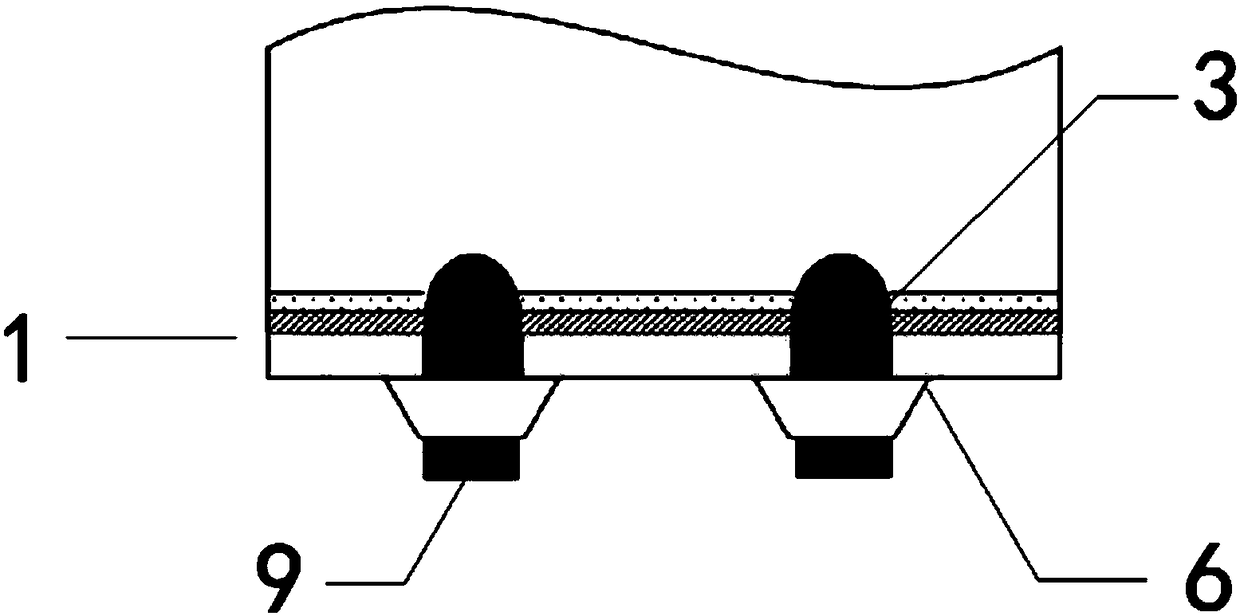

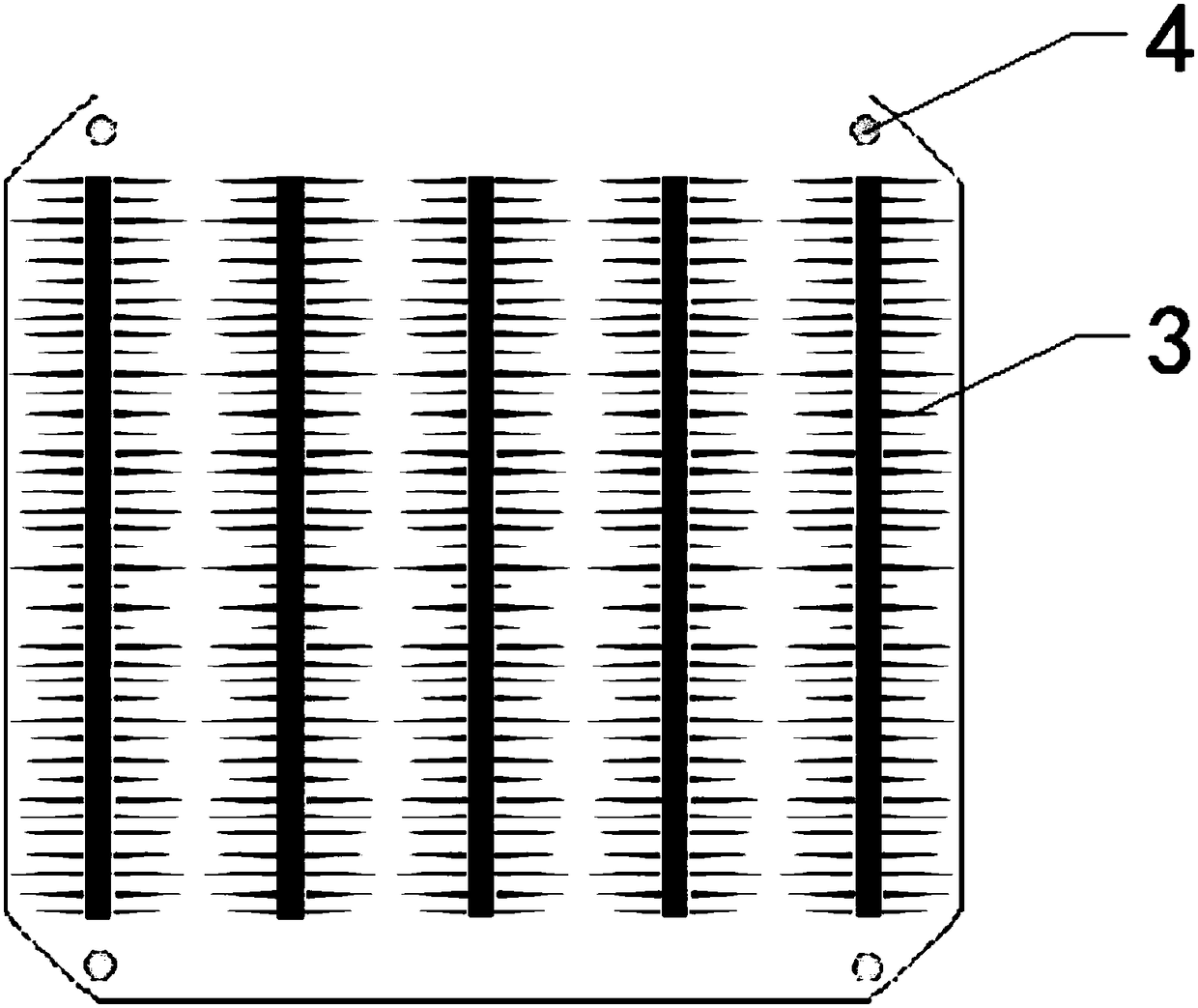

[0040] The manufacturing process of PERC-based bifacial solar cells with five busbar structures is as follows:

[0041] 1) P-type monocrystalline silicon wafers are cleaned to remove impurities and surface defects, and double-sided textured to form a 2-6um random pyramid textured surface.

[0042] 2) Back-to-back diffusion, negative pressure diffusion phosphorus source on the front side of the silicon wafer to prepare 0.3um deep PN junction.

[0043] 3) Remove the PSG on the front side, remove the excess diffused PN junction at the side boundary, and properly polish and correct the suede 2-4um on the back side.

[0044] 4) Double-sided oxidation and annealing to form a 3-7nm silicon dioxide film.

[0045] 5) ALD reaction deposition of Al with a film thickness of 4-6nm on the back surface 2 o 3 film.

[0046] 6) Double-sided PECVD reaction deposition of Si 3 N 4 For the thin film, a silicon nitride anti-reflection passivation protective film of 75-90nm is deposited on the...

Embodiment 2

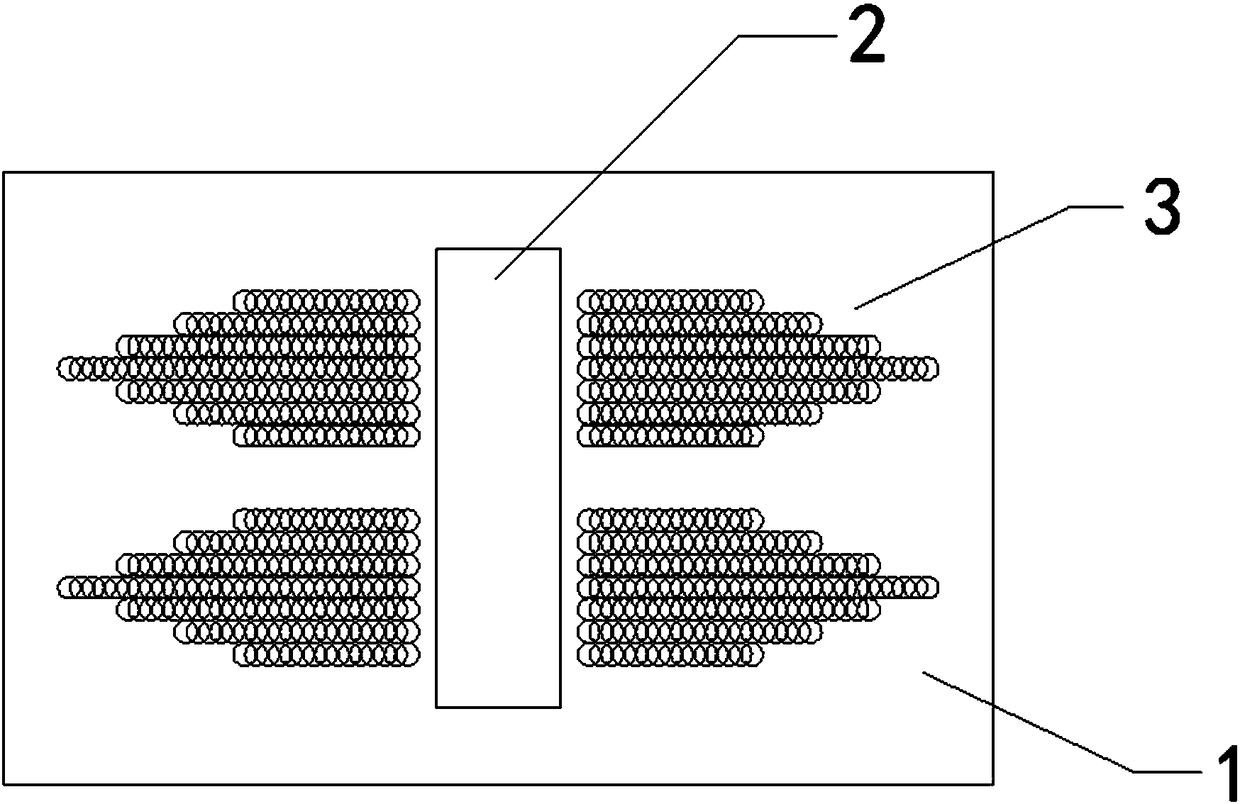

[0053] On the basis of Embodiment 1, the silver paste printing pair with the same pattern and a diameter of 0.3 mm is marked on the corresponding position of the silver bus grid electrode screen with a length of 155.5 mm and a width of 0.8 mm on the back side of the silver bus grid electrode 8. Fitting point 1, and make the center of the alignment fitting point 1 printed with silver paste and the alignment fitting point 5 printed with aluminum paste concentric, and the center of the alignment fitting point 1 printed with silver paste is located in the extended area of the silver bus grid electrode area 2 on the coverage area. Then, the silver paste printing machine captures the aluminum paste printing alignment fitting point 5 marked by the aluminum paste printing machine, and the CCD camera of the silver paste printing machine adjusts the X, Y and angle of the screen to make the silver paste printing alignment fitting point 5 The center of joint point 1 is aligned with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| Line length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com