Copper-containing wastewater treatment technology and application

A wastewater treatment and process technology, which is applied in water/sewage treatment, water treatment parameter control, oxidized water/sewage treatment, etc. It can solve the problem that the biochemical treatment process is difficult to operate stably, cannot stably reach the effluent standard, and the treatment and maintenance costs are expensive. and other problems, to achieve the effect of improving ozone utilization rate, low gas-liquid mass transfer resistance, and improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0170] The actual electroless plating wastewater was taken from an electroplating wastewater treatment plant in a park in Dongguan. The copper-containing wastewater was tested to compare the water quality of the wastewater before and after treatment. Further, the copper-containing wastewater used in this embodiment is wastewater from a pH correction pool in an electroplating wastewater treatment plant in a park in Dongguan.

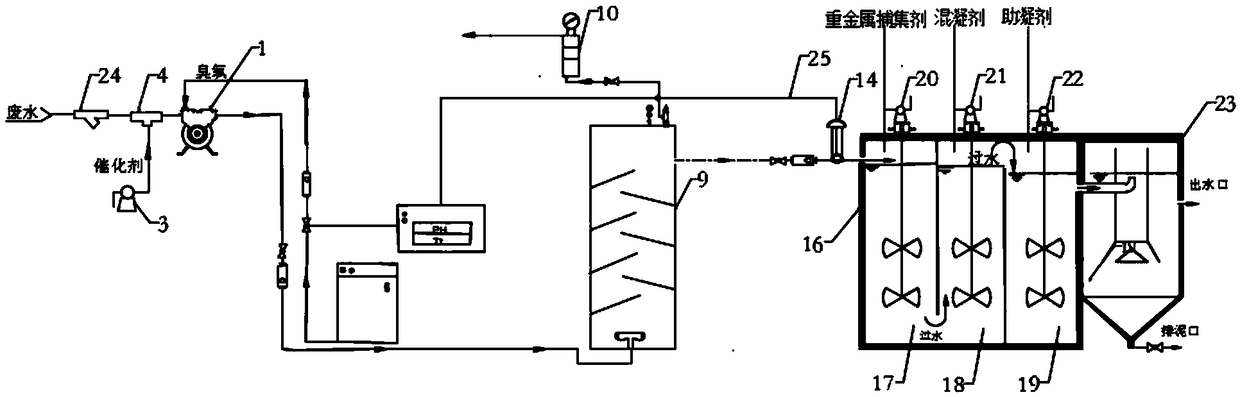

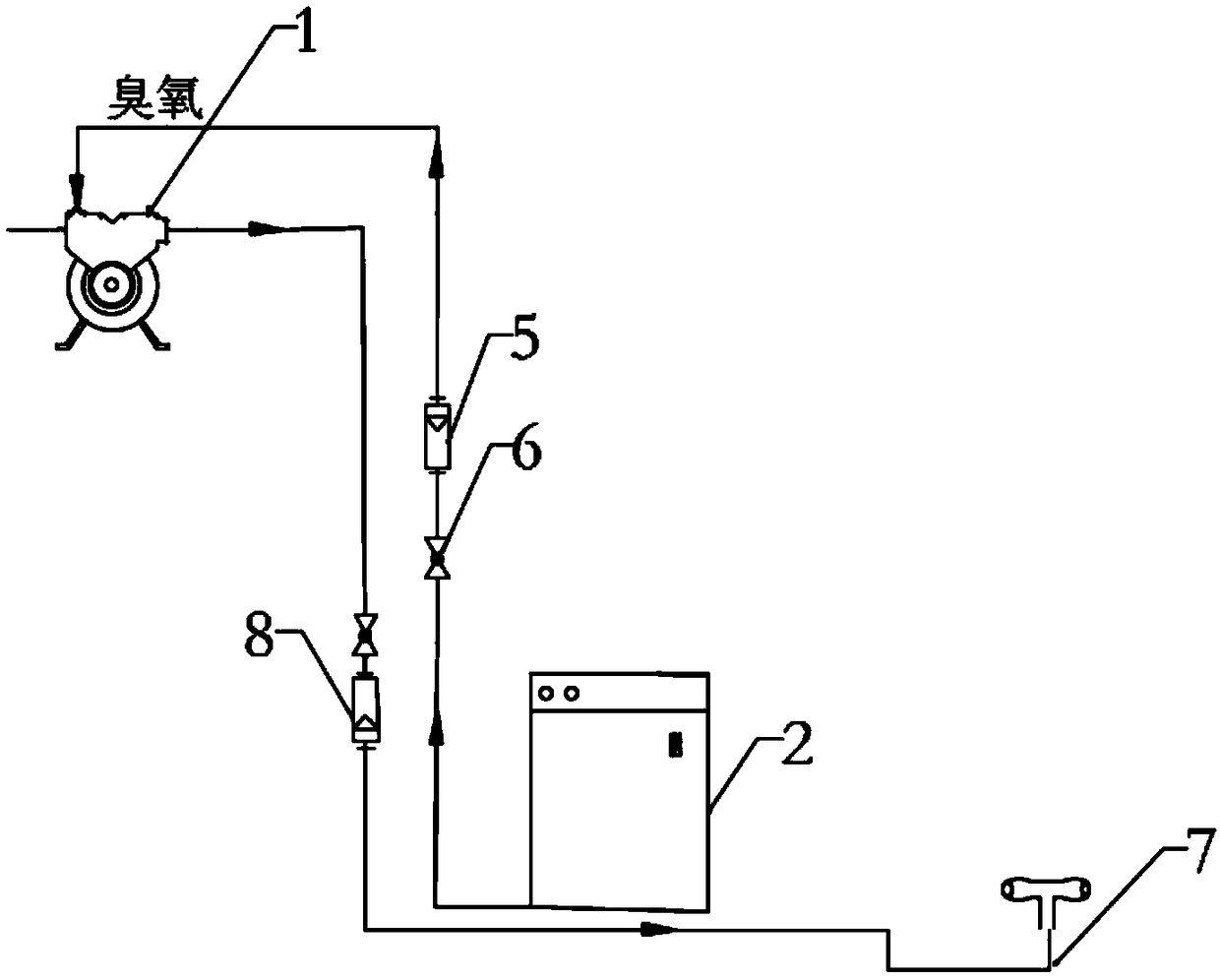

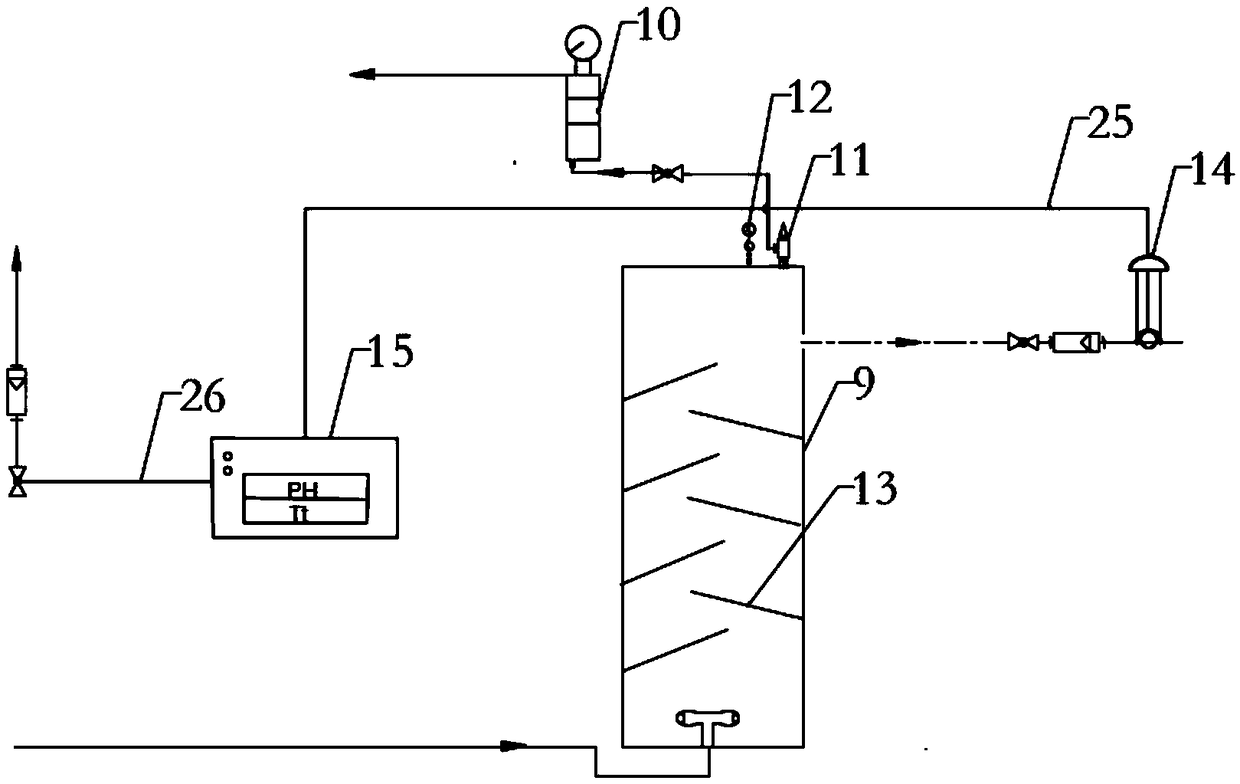

[0171] refer to figure 1 -4, the catalyst dosing device 3, the dosing pipe and the three-way interface 4 are connected, and the water inlet pipeline of the dissolved air pump 1 is provided with a three-way interface 4, and the catalyst passes through the catalyst dosing device 3, the dosing pipe and the three-way interface 4 Throw it into copper-containing waste water; the intake line of the dissolved air pump 1 is connected to the gas supply line of the ozone generator 2, and a gas flow meter 5 and a gas volume regulating valve 6 are arranged on the gas ...

Embodiment 2

[0187] A copper-containing wastewater treatment process, the difference from Example 1 is that in this example:

[0188] The gas-liquid mixing ratio is 1:9;

[0189] The dosage of hydrogen peroxide catalyst is 4mL / L;

[0190] The dosing concentration of DTC heavy metal collector is 80mg / L, the dosing concentration of coagulant PAC (polyaluminum chloride) is 70mg / L, and the dosing concentration of coagulant PAM (polyacrylamide) is 8mg / L L;

[0191] The chelated heavy metal pollutants flow into the vertical flow sedimentation tank after flocculation and coagulation. After sedimentation, the heavy metal pollutant flocs are deposited at the bottom of the tank.

[0192] In this embodiment, after being dispersed by the micro-nano bubble aeration head, the dissolution of ozone is accelerated, the mass transfer efficiency of gas and liquid is reduced, and the utilization rate of ozone reaches 96%, which greatly improves the utilization rate of ozone.

[0193] The water quality of t...

Embodiment 3

[0198] The copper-containing wastewater used in this example is copper-containing wastewater collected separately from an electroplating wastewater treatment plant in a park in Qingyuan.

[0199] refer to figure 1 -4. A copper-containing wastewater treatment process, comprising the following steps:

[0200] Fill the water tank with copper-containing wastewater to be treated, turn on the ozone generator air pump switch, wait for the air intake to stabilize for 3 minutes, turn on the circulating water cooling device, and control the temperature of the circulating water at 15°C. After ensuring that the cooling water flows into the ozone generator tube stably, turn on the ozone switch and adjust the ozone concentration and oxygen flow to 80% and 5L / min respectively; after the ozone is output stably, turn on the dissolved air pump and control the gas-liquid mixing ratio to 1:8 , inhale ozone and copper-containing wastewater to be treated at the same time, and initially dissolve oz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com