Automatic lens assembly machine

An automatic assembly machine and lens technology, applied in installation, optics, instruments, etc., can solve problems affecting production efficiency, causing equipment waiting time, and inaccurate center positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make your examiner further understand the present invention, hereby give a preferred embodiment, and cooperate with the drawings to describe in detail as follows:

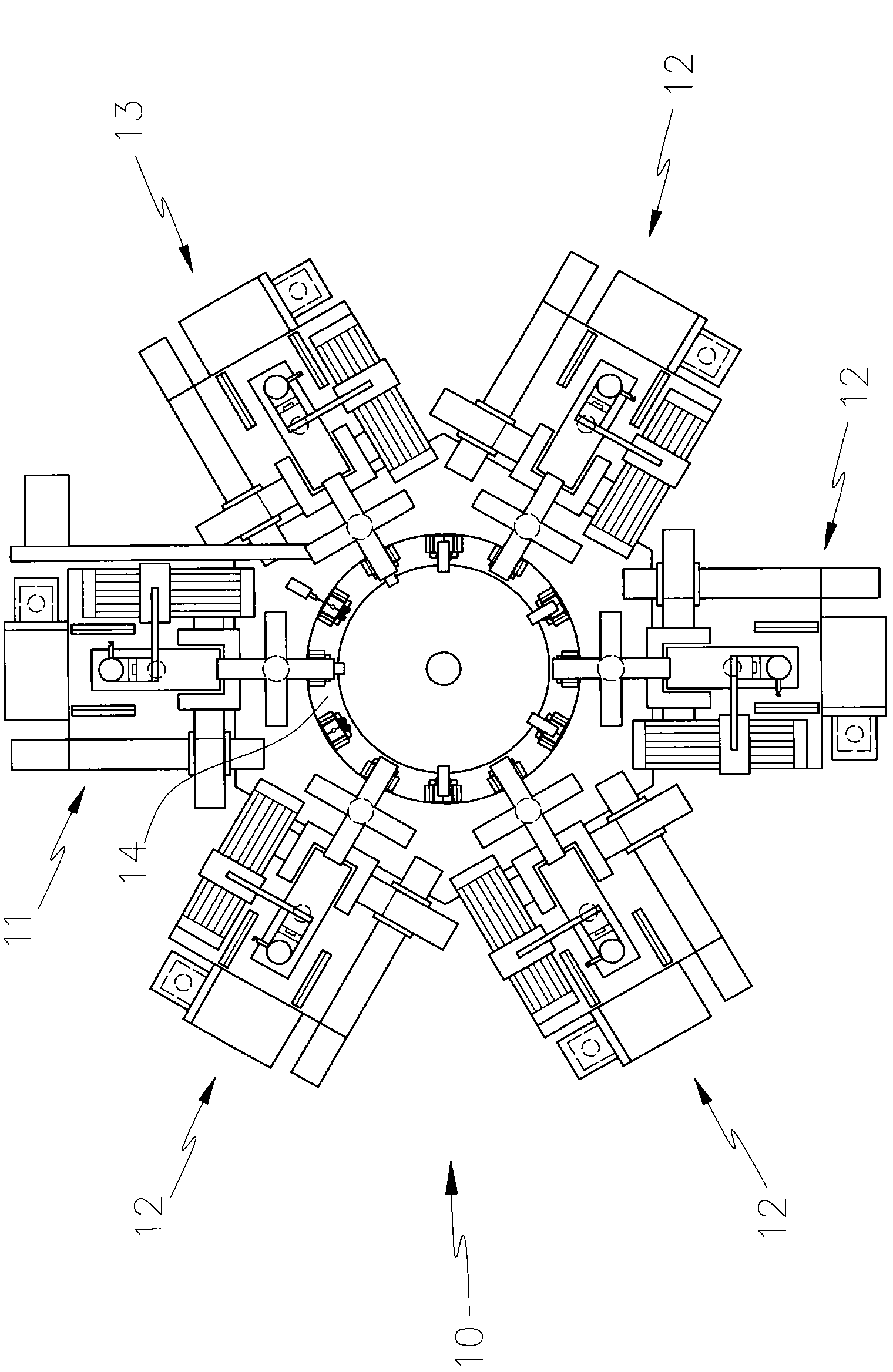

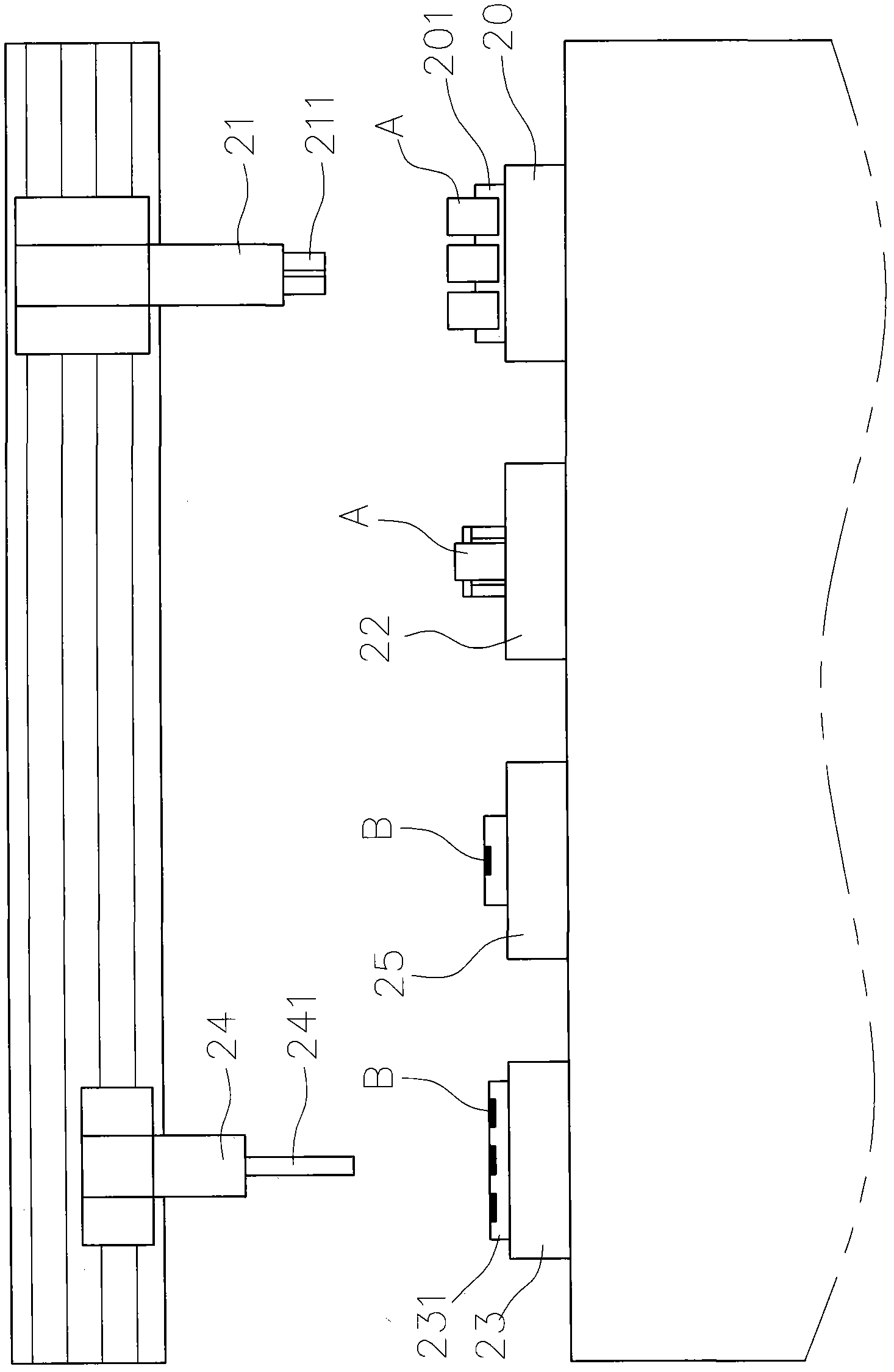

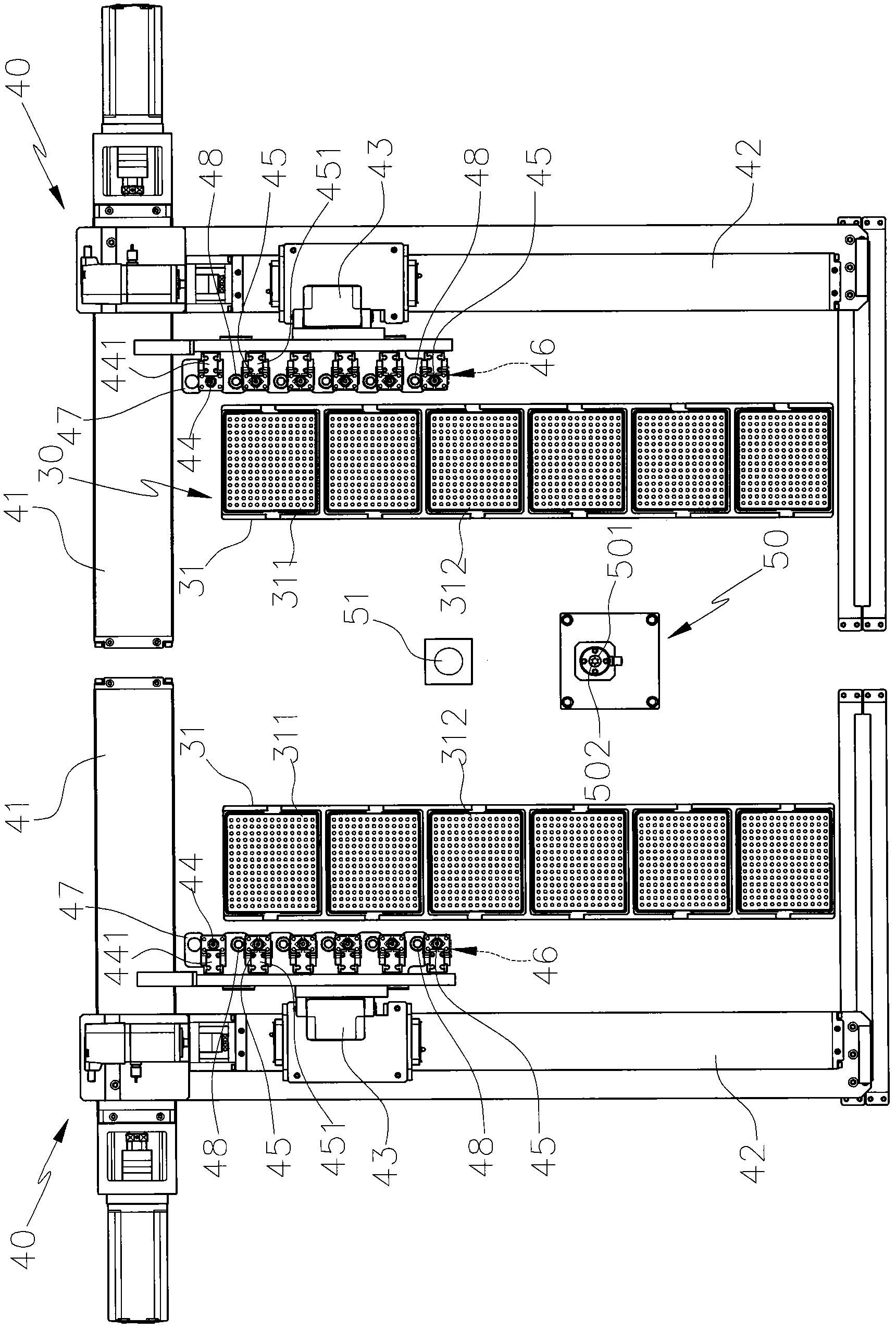

[0043] see image 3 , Figure 4 , Figure 5 , the automatic lens assembly machine of the present invention includes a feeding and receiving device 30, two transfer devices 40 and an assembly stand 50; the feeding and receiving device 30 is used to hold several lens elements; in this embodiment, the feeding and receiving device The device 30 is respectively provided with bearing seats 31 on the two sides of the assembling base 50, and according to the assembly type, several lens components are respectively supported, such as a tray (Tray) 311 for bearing the lens barrel, and a A plurality of trays (Tray) 312 for the lens are used for two transfer devices 40 to take materials; the two transfer devices 40 are relatively arranged on the side of the assembly base 50, and are respectively provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com