Biaxial numerical control machine tool correction positioning implementation method and system based on counterpoint platform

A technology of alignment platform and CNC machine tools, which is applied in the control system of CNC machine tools and the field of two-axis CNC machine tool processing, can solve the problems of higher positioning accuracy, unsatisfactory processing accuracy, and difficult positioning and calibration, so as to improve processing efficiency , low cost and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to describe the technical content of the present invention more clearly, further description will be given below with reference to specific embodiments.

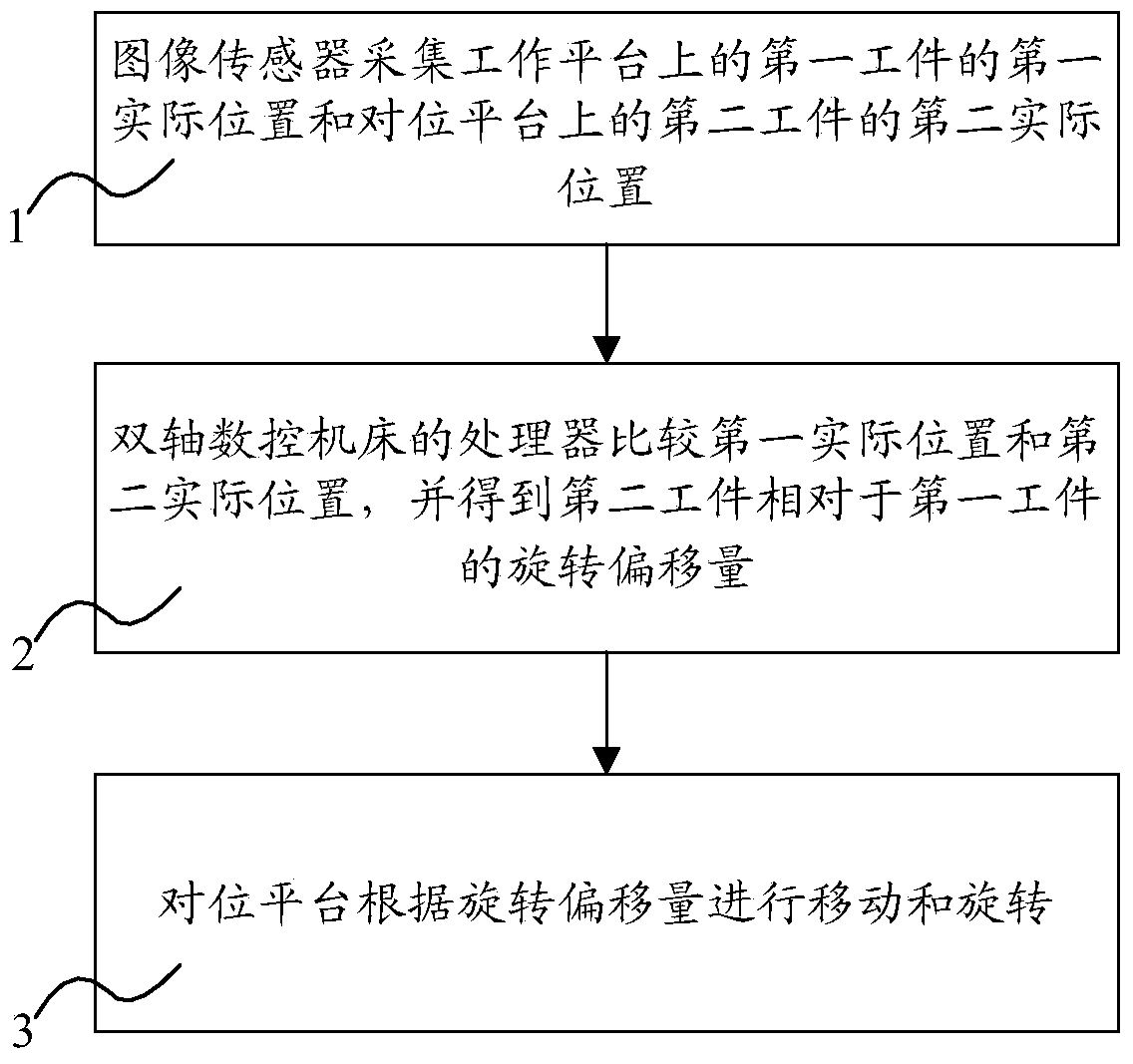

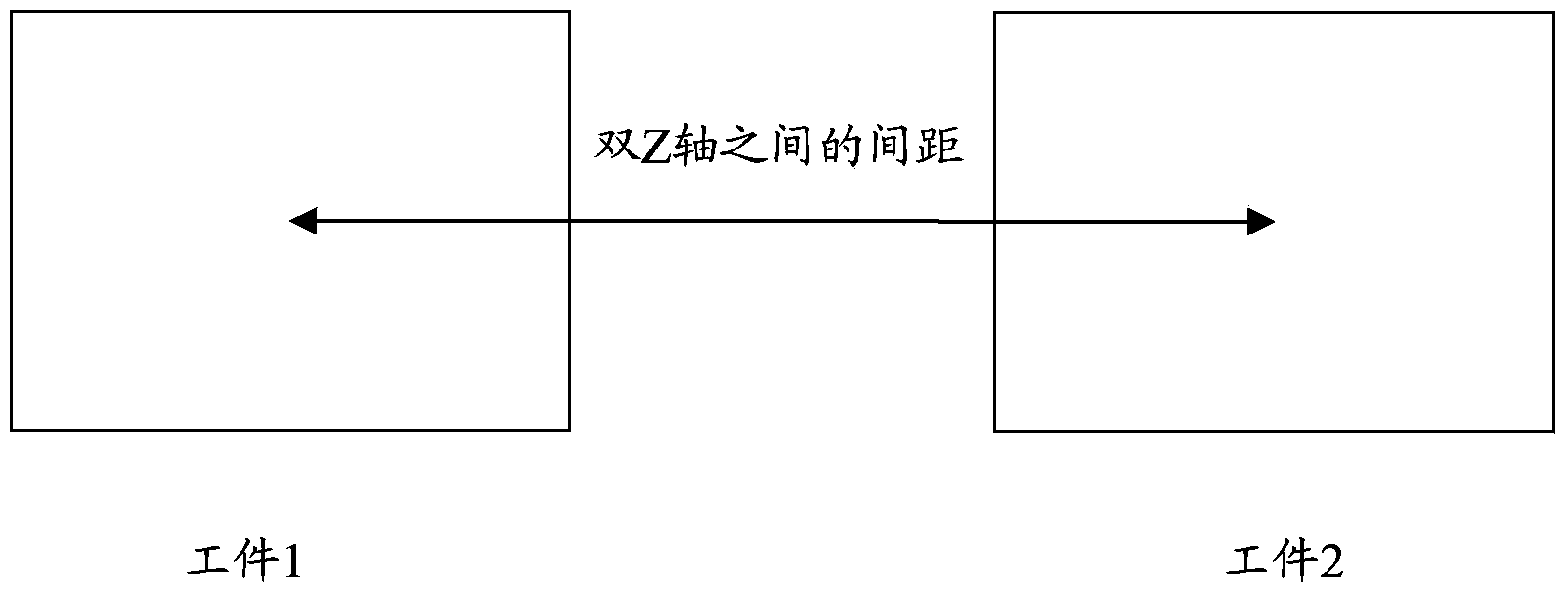

[0035] see figure 1 , in one embodiment, the alignment platform is placed on the working platform of the two-axis CNC machine tool, the first workpiece is placed on the working platform, and the second workpiece is placed on the alignment platform. The present invention is based on the alignment The method for realizing the correction and positioning of a two-axis CNC machine tool by a bit platform includes the following steps:

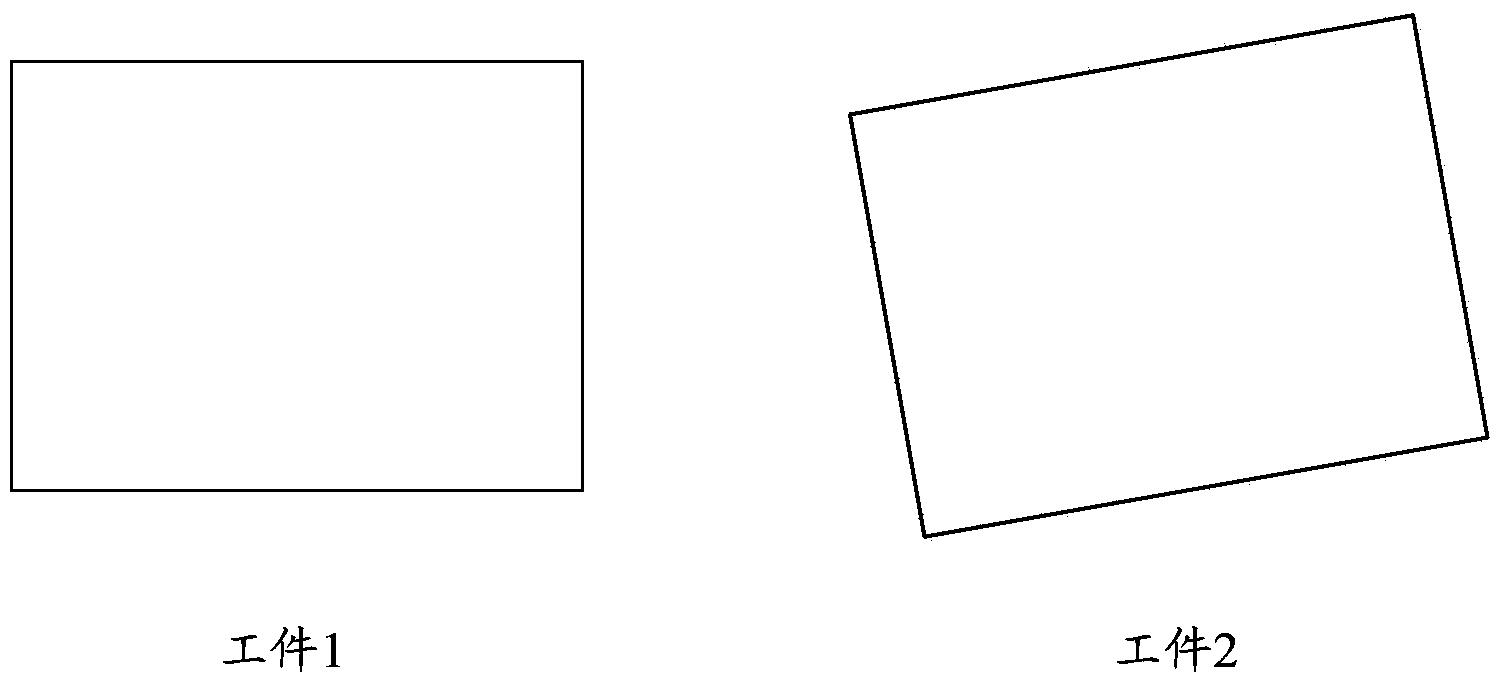

[0036] (1) The image sensor collects the first actual position of the first workpiece on the working platform and the second actual position of the second workpiece on the alignment platform;

[0037] (2) The processor of the two-axis numerical control machine tool compares the first actual position and the second actual position, and obtains the rotational offset of the second work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com